Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT ADJUSTMENT, INSPECTION AND REPLACEMENT)

TEMPERATURE RESISTANCE (OHMS)

°C °F NOMINAL LOW HIGH

-30 -22 12600 11800 13400

-20

-4

11400 11000 11800

-10

14

9500 8000 11000

0 32 5900 4900 6900

10 50 3800 3100 4500

20 68 2500 2200 2800

30 86 1700 1500 1900

40 104 1200 1080 1320

50 122 840 750 930

60 140 630 510 750

70 158 440 370 510

80 176 325 280 370

90 194 245 210 280

100 212 195 160 210

110 230

145

125 160

120 248

115

100 125

CONVERSION CHART FOR TEMPERATURE SENSORS

The resistance value of a temperature sensor may

test good at a certain temperature but it might be

defective at other temperatures. If in doubt, try a

new sensor.

Also remember this validates the operation of the

sensor at ambient temperature. It does not val-

idate the over temperature functionality. To test

it, the sensor could be removed from the engine/

muffler and heated with a heat gun while it is still

connected to the harness to see if the ECM will

detect the high temperature condition and gener-

ate a fault code.

When working with injectors, the resistance value

might test good while the complete current would

notflowthroughthewirewhenpulsatingcurrent

is supplied to the injector in its normal operation.

A solution would be to use a jumper wire to di-

rectly supply the injector from the VCM. If it now

works, replace the defective wire. A Noid light

(available from after-market tool/equipment sup-

pliers) may also be used to validate the injector

operation.

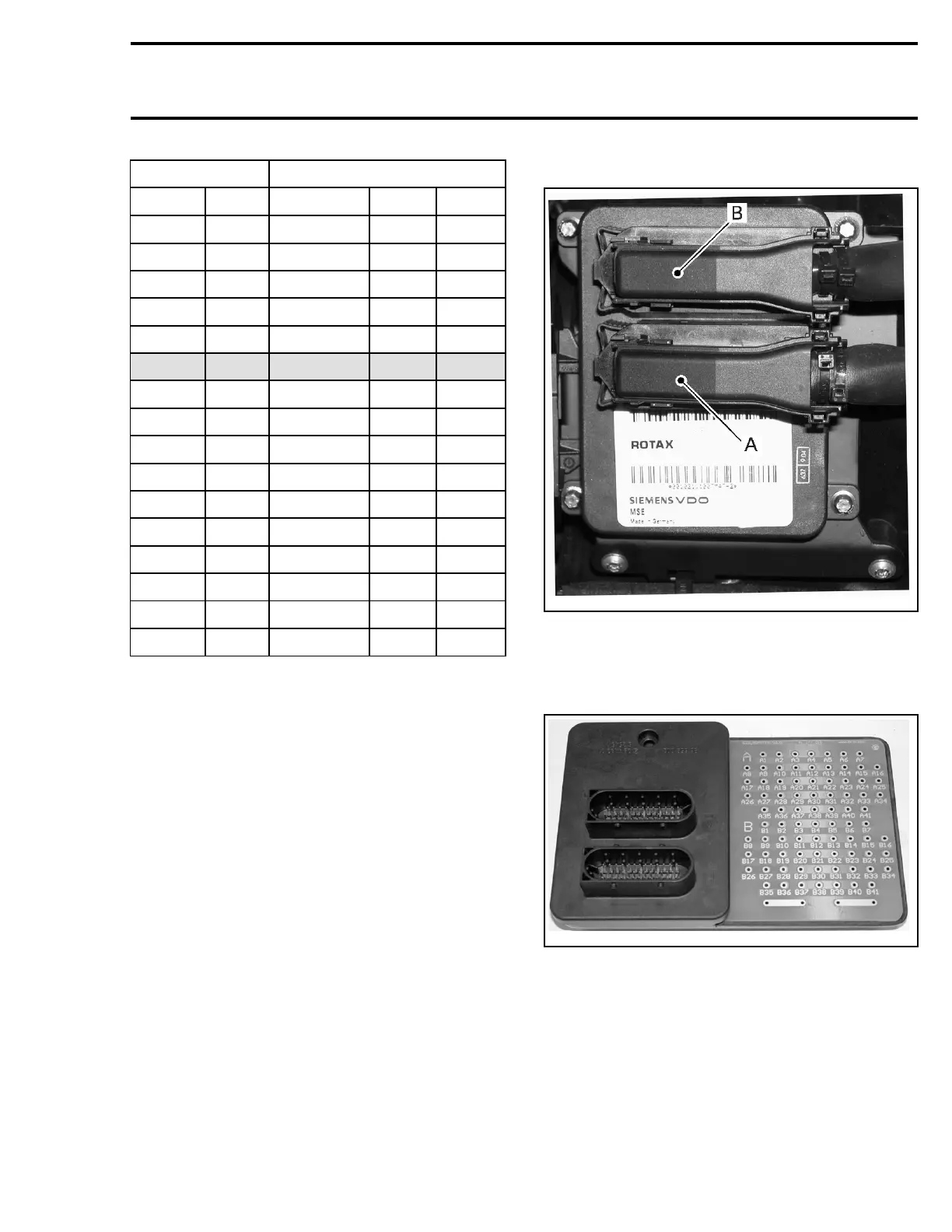

ECM Connectors

smr2005-056-004_a

ECM CONNECTORS IDENTIFICATION

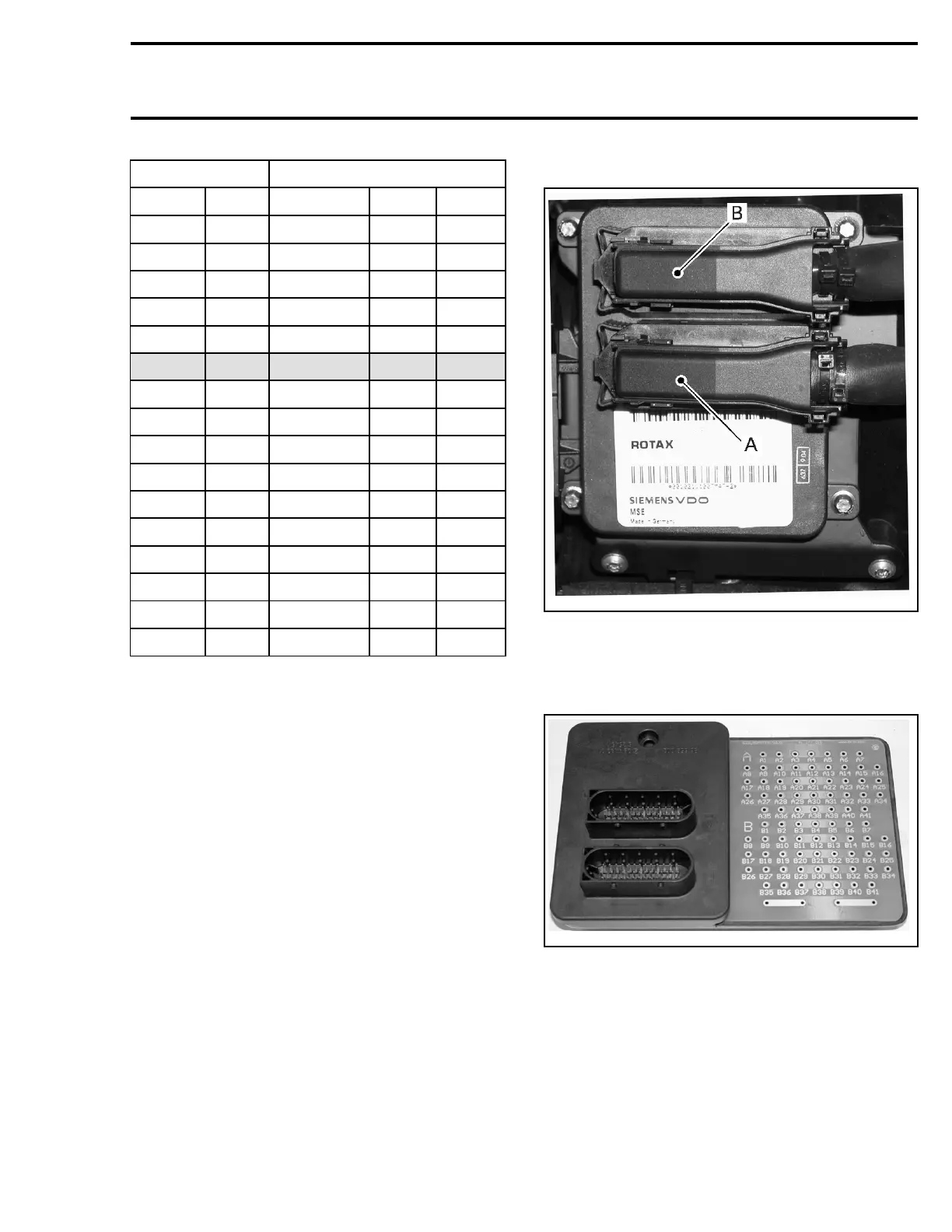

The most recommended and safest method to

probe ECM connector terminals is to use the ECM

adapter (P/N 420 277 010).

420277010

This tool will prevent deforming or enlarging termi-

nals which would lead to bad ECM terminal con-

tact creating intermittent or permanent problems.

Disconnect the desired 1connector from ECM and

reconnect on the tool connector. Probe required

terminals directly in the tool holes.

smr2005-056 127

Loading...

Loading...