Section 09 PROPULSION

Subsection 01 (JET PUMP)

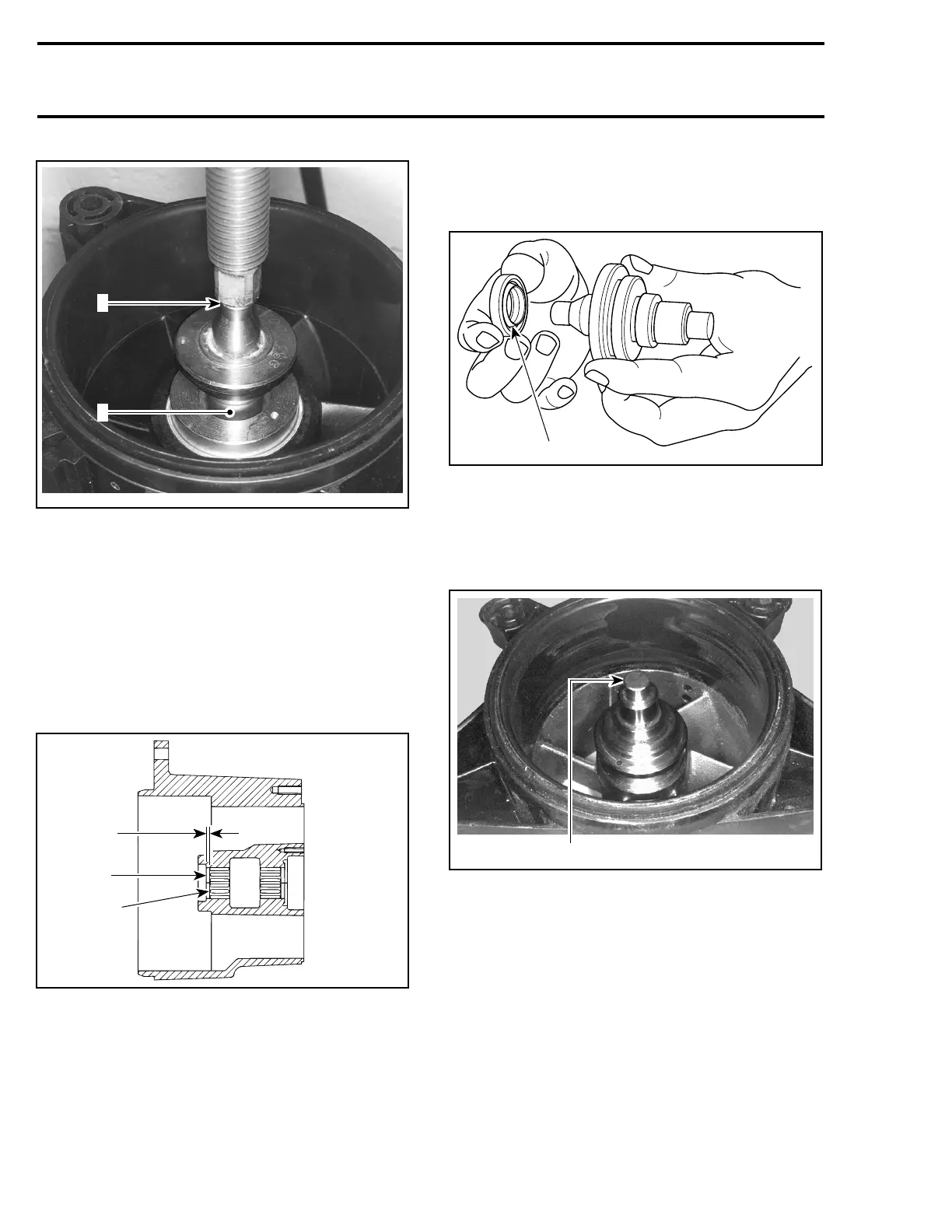

F00J0ZA

1

2

1. Press on tool until it stops

2. Bearing

CAUTION: These tools have been designed to

properly position bearings and seal, thus pro-

viding space for lubrication purposes. The tool

flanges allow this. If a different pusher type is

being used, components must be properly po-

sitioned as follows.

Bearingonimpellersidemustbe1.5to2.5mm

(.060 - .100 in) inside reservoir measured from seal

seat. Refer to following illustration.

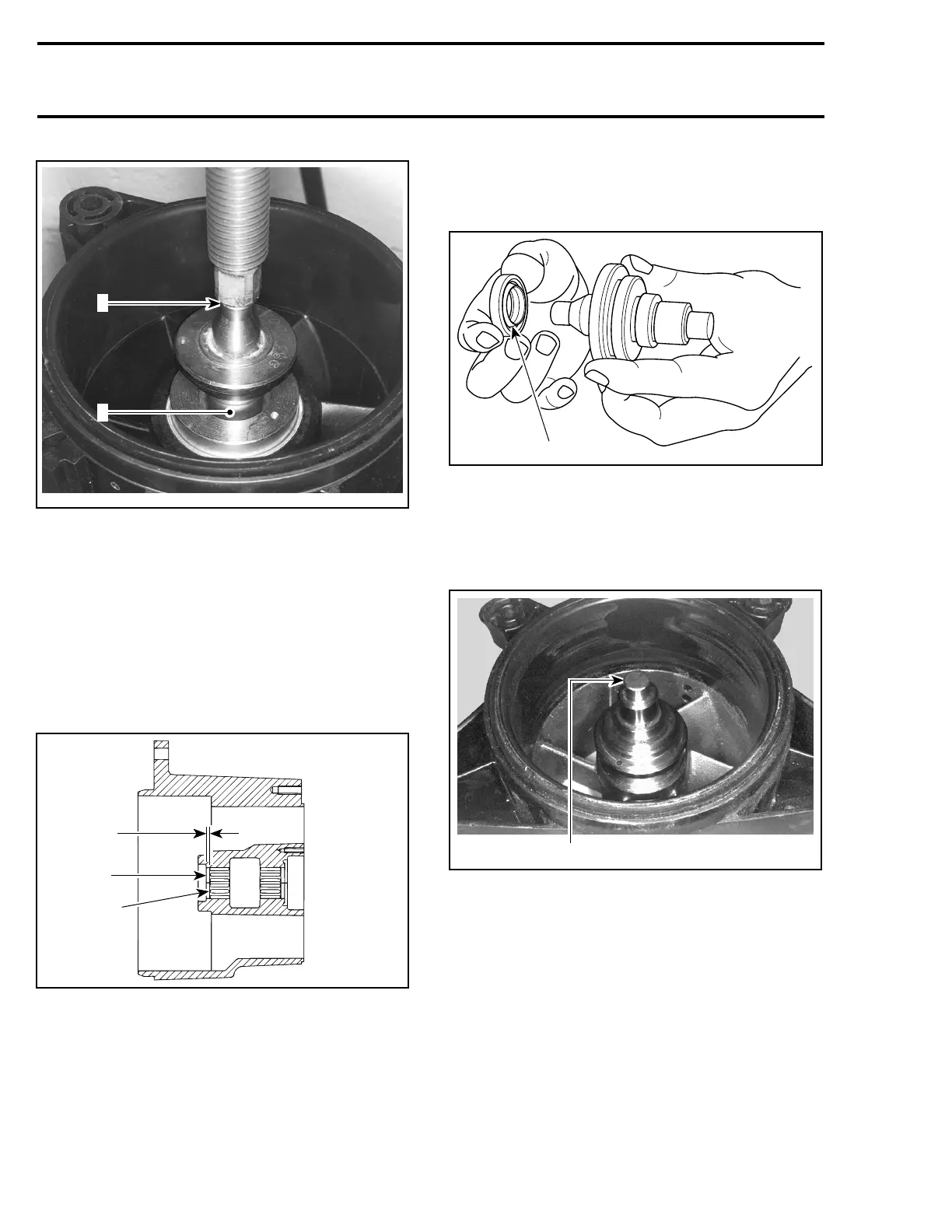

F01J5YA

A

1

2

1. Seal seat

2. Stamped end of bearing

A. 1.5 - 2.5 mm (.060 - .100 in)

Apply Loctite 518 (P/N 293 800 038) to seal hous-

ing, all around outer diameter and on seal seat.

Properly insert seal on tool.

NOTE: Apply synthetic grease (P/N 293 550 010)

on tool to ease seal insertion.

Install seal with the spring toward the outside.

F01J1KA

1

1. Spring of seal facing tool

CAUTION: Prevent sealant from contacting any

needles of bearing.

Push on tool end with a press until tool flange con-

tacts housing.

F00J0CA

1

1. Press on tool until it stops

Apply synthetic grease (P/N 293 550 010) be-

tween seal lips.

244 smr2005-062

Loading...

Loading...