TOMATECH AUTOMATION

Program:

O0005;

G00 X176 Z10 M03 S500 (Change No.2 tool and execute its compensation, spindle

CW rotation with 500 r/min)

G72 W2.0 R0.5 F300; (Tool infeed 2mm, tool retraction 0.5mm)

G72 P10 Q20 U0.2 W0.1; (Roughing a--d,X roughing allowance 0.2mm and Z 0.1mm)

Ⅰ Programming

N10 G00 Z-55 S800 ; (Rapid traverse)

G01 X160 F120; (Infeed to a point)

X80 W20; (Machining a—b) Blocks for finishing path

W15; (Machining b—c)

N20 X40 W20 ; (Machining c—d)

G70 P050 Q090 M30; (Finishing a—d)

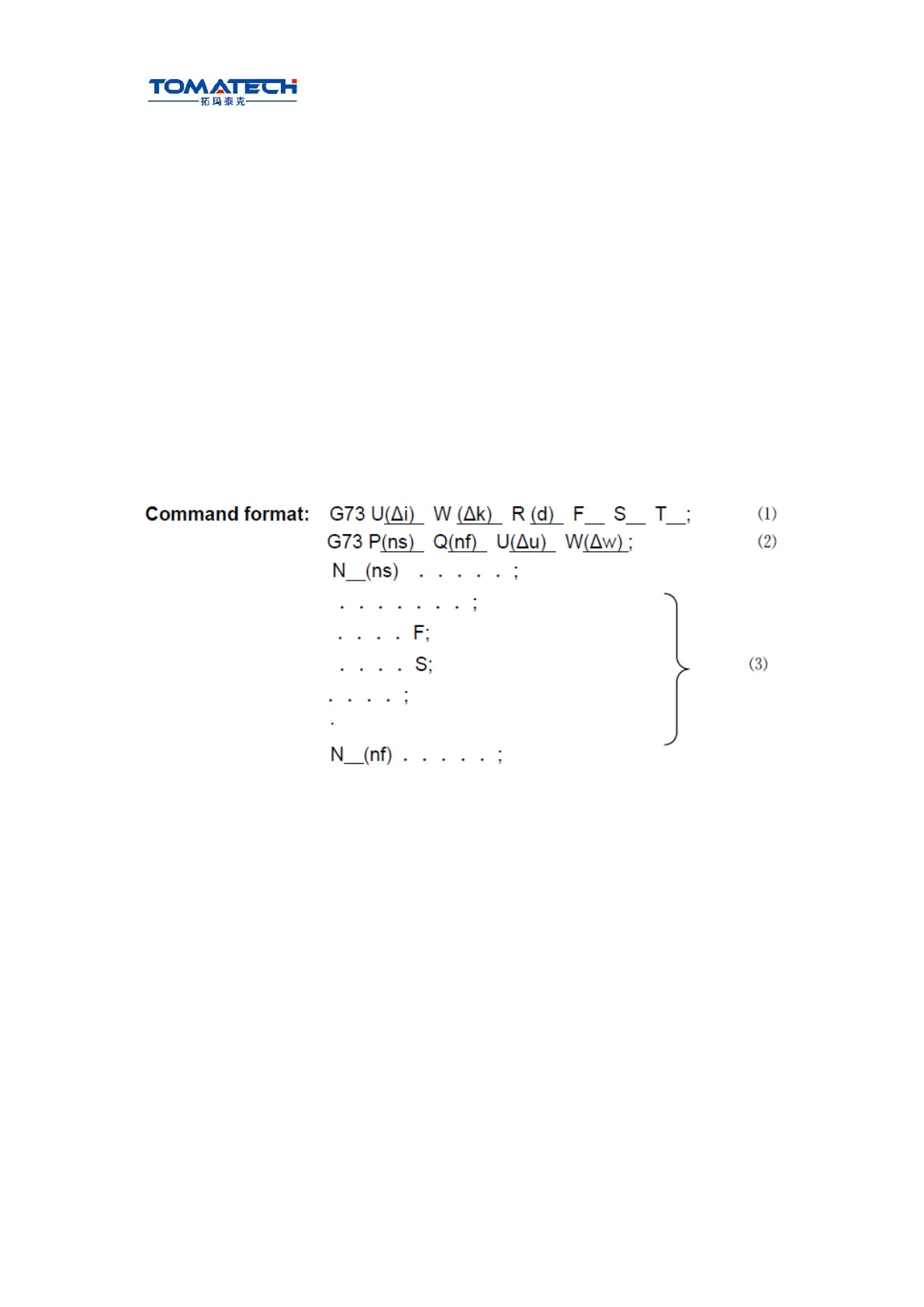

3.20.3 Closed cutting cycle G73

Command functions: G73 is divided into three parts:

⑴ Blocks for defining the travels of tool infeed and tool retraction, the cutting speed, the

spindle speed and the tool function when roughing;

⑵ Blocks for defining the block interval, finishing allowance;

⑶ Blocks for some continuous finishing path, counting the roughing path without being

executed actually when executing G73.

According to the finishing allowance, the travel of tool retraction and the cutting times, the

system automatically counts the travel of roughing offset, the travel of each tool infeed

and the path of roughing, the path of each cutting is the offset travel of finishing path, the

cutting path approaches gradually the finishing one, and last cutting path is the finishing

one according to the finishing allowance. The starting point and end point of G73 are the

same one, and G73 is applied to roughing for the formed rod. G73 is non-modal and its

path is shown in Fig.3-31.

Relevant definitions:

Finishing path: The above-mentioned Part 3 of G73 (ns~nf block)defines the finishing

path,and the starting point of finishing path (start point of ns block)is the same these

of starting point and end point of G73, called A point; the end point of the first

Loading...

Loading...