TOMATECH AUTOMATION

� Diameter or radius programming: currently, because there is only one bit parameter No

1.2 to select the diameter or the radius programming and is valid to only X axis, Z and Y

axis use the only radius programming in G2, G3, and X axis is selected by the parameter;

� The tool nose direction of C tool compensation is 0 in G17, G19.

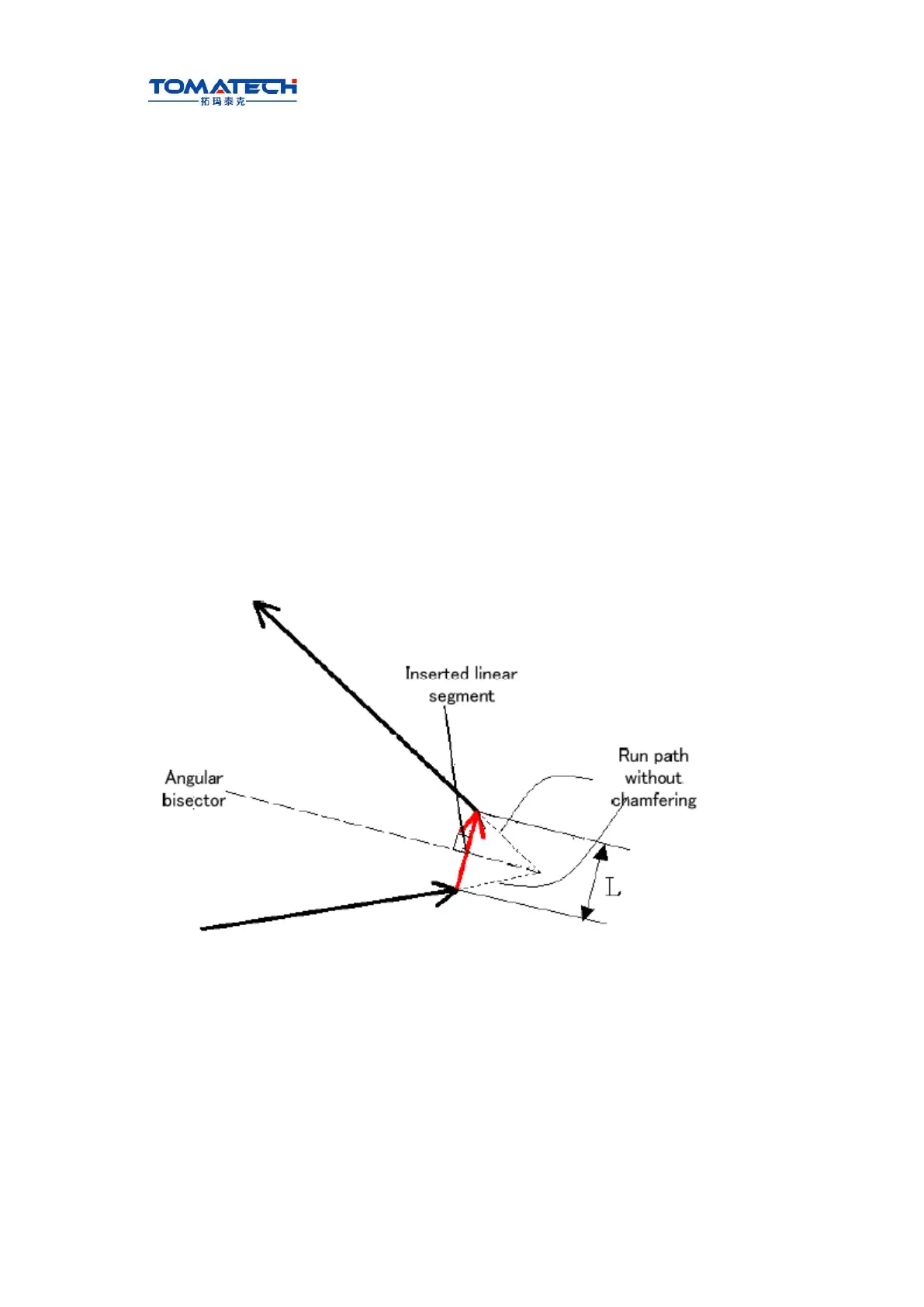

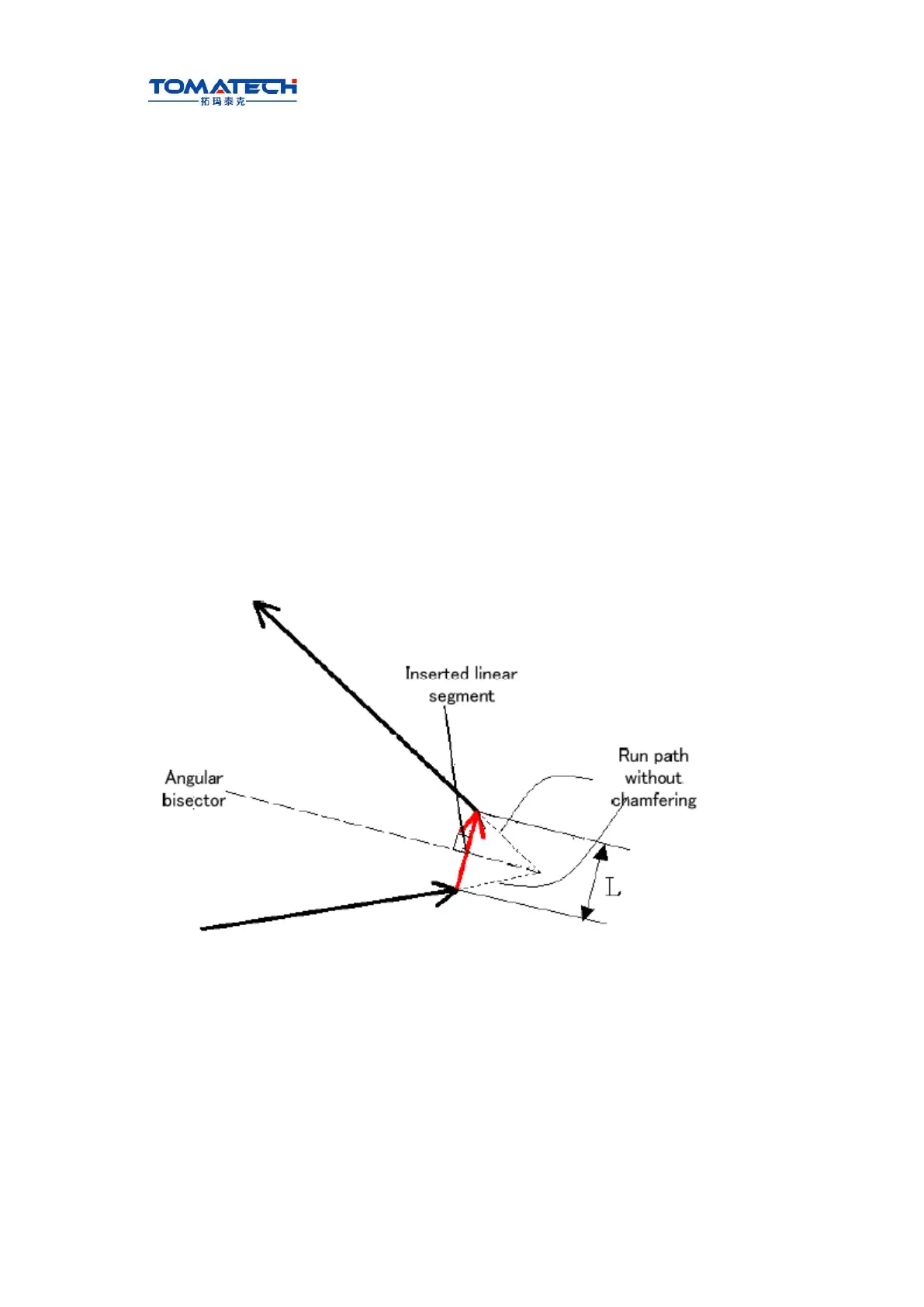

3.11 Chamfering Function

Chamfering function is to insert one straight line or circular between two contours to make

the tool smoothly transmit from one contour to another one.TAC-1002T uses the linear

and circular chamfering functions.

3.11.1 Linear chamfering

Linear chamfering: insert one straight line in the linear contours, arc contours, linear

contour and arc contour. The command address of linear chamfering is L, behind which

data is the length of chamfering straight line. The linear chamfering must be used in G01,

G02 or G03 command.

A. Linear to linear

Command format: G01 X(U)_ Z(W)_ L_ ;

G01 X(U)_ Z(W)_ ;

Ⅰ

Programming

Command function: insert one straight line between two linear interpolation blocks.

B. Linear to circular

Command format: G01 X(U)_ Z(W)_ L_;

G02/G03 X(U)_ Z(W)_ R_;

Or

G01 X(U)_ Z(W)_ L_;

G02/G03 X(U)_ Z(W)_ I_ K_;

Command function: insert one straight line between the linear and circular interpolation

blocks.

Loading...

Loading...