TOMATECH AUTOMATION

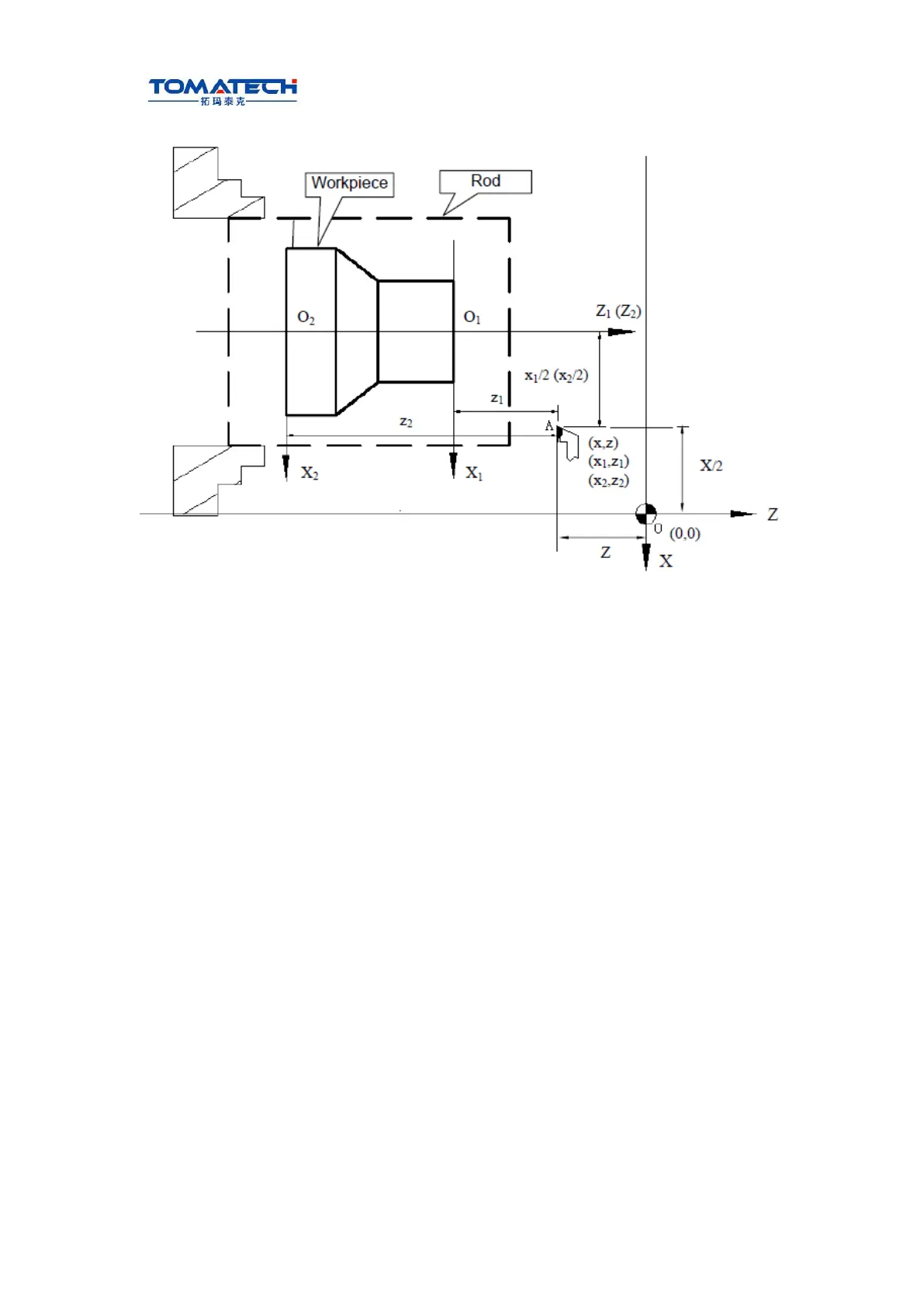

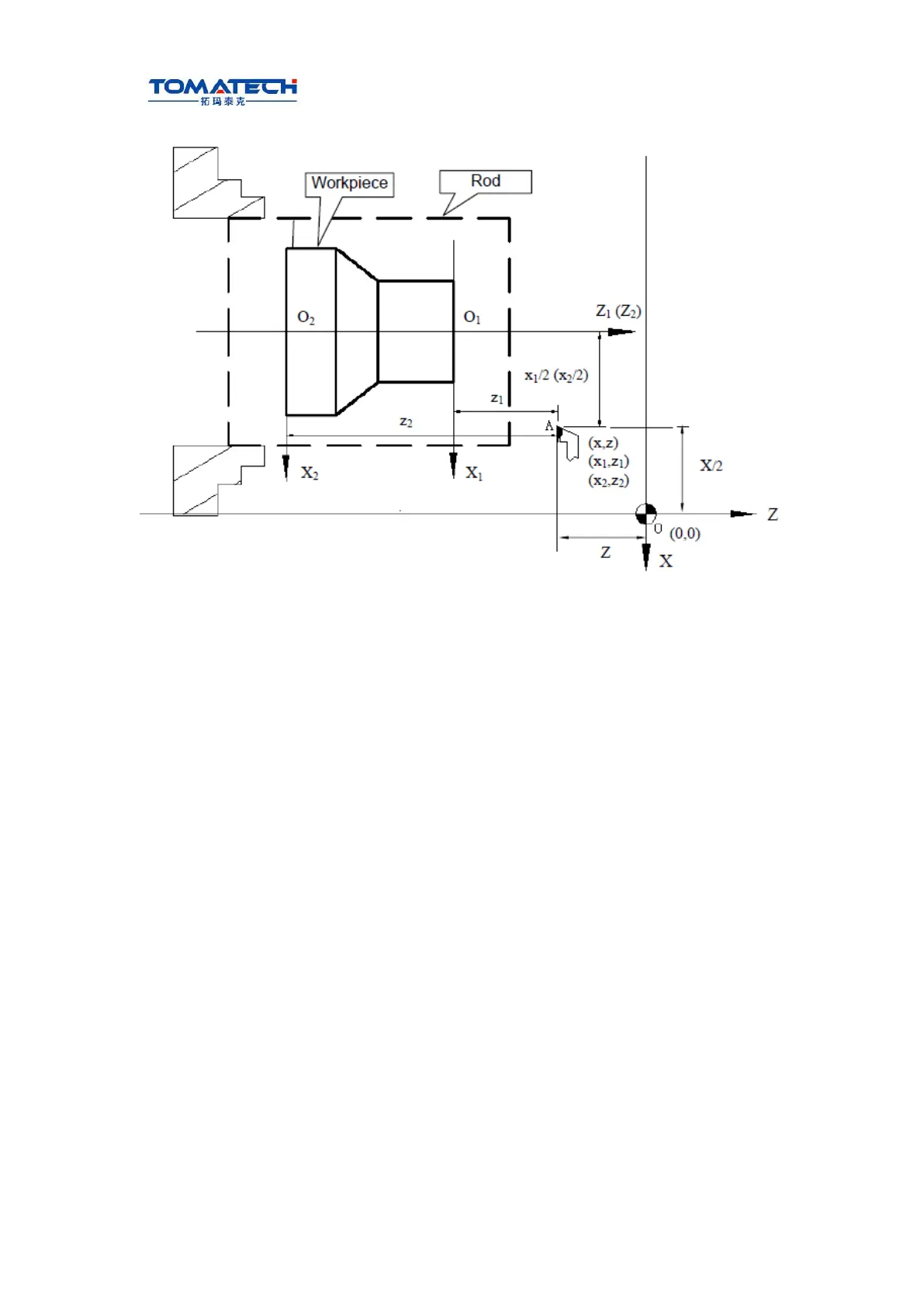

Fig. 1-6

In the above figure, XOZ is the coordinate system of machine tool, X1O1Z1 is the

workpiece coordinate system of X axis located at the heading of workpiece, X2O2Z2 is the

one of X axis located at the ending of workpiece, O point is the machine reference point, A

point is the tool nose and Fig. 1-6

Programming

coordinates of A point in the above-mentioned coordinate systems is as follows:

A point in the machine tool coordinate system: (x,z);

A point in X1O1Z1 coordinate system: (x1,z1);

A point in X2O2Z2 coordinate system: (x2,z2).

1.3.4 Interpolation function

Interpolation is defined as a planar or three dimensional contour formed by path of 2 or

multiple axes moving at the same time, also called Contour control. The controlled

moving axis is called link axis when the interpolation is executed. The moving distance,

direction and speed of it are controlled synchronously in the course of running to form the

required Composite motion path. Positioning control is defined that motion end point of

one axis or multiple axes instead of the motion path in the course of running is controlled.

TAC-100XT X and Z axis are link axes and 2 axes link CNC system. The system

possesses linear, circular and thread interpolation function.

Linear interpolation: Composite motion path of X, Z axis is a straight line from starting

point to end point.

Circular interpolation: Composite motion path of X, Z axis is arc radius defined by R or the

circle center (I, K) from starting point to end point.

Thread interpolation: Moving distance of X or Z axis or X and Z axis is defined by rotation

angle of spindle to form spiral cutting path on the workpiece surface to realize the

Loading...

Loading...