TOMATECH AUTOMATION

N010 G90 X20.0 Z10.0 F400;

N011 ; (execute G90 one time repetitively)

…

4) Pause or single block is executed in G90, G94, the single block stops after the tool

moves end

point of current path.

(Outer cutting Φ120)

(C→B→A,cutting Φ60) rogramming

3.20 Multiple Cycle Commands

Multiple cycle commands of the system includes axial roughing cycle G71, radial roughing

cycle G72, closed cutting cycle G73, finishing cycle G70, axial grooving multiple cycle

G74, axial grooving multiple cycle G75 and multiple thread cutting cycle G76. When the

system executes these commands, it automatically counts the cutting times and the

cutting path according to the programmed path, travels of tool infeed and tool retraction,

executes multiple machining cycle (tool infeed → cutting→retract tool→tool infeed ),

automatically completes the roughing, finishing

workpiece and the starting point and the end point of command are the same one.

3.20.1 Axial roughing cycle G71

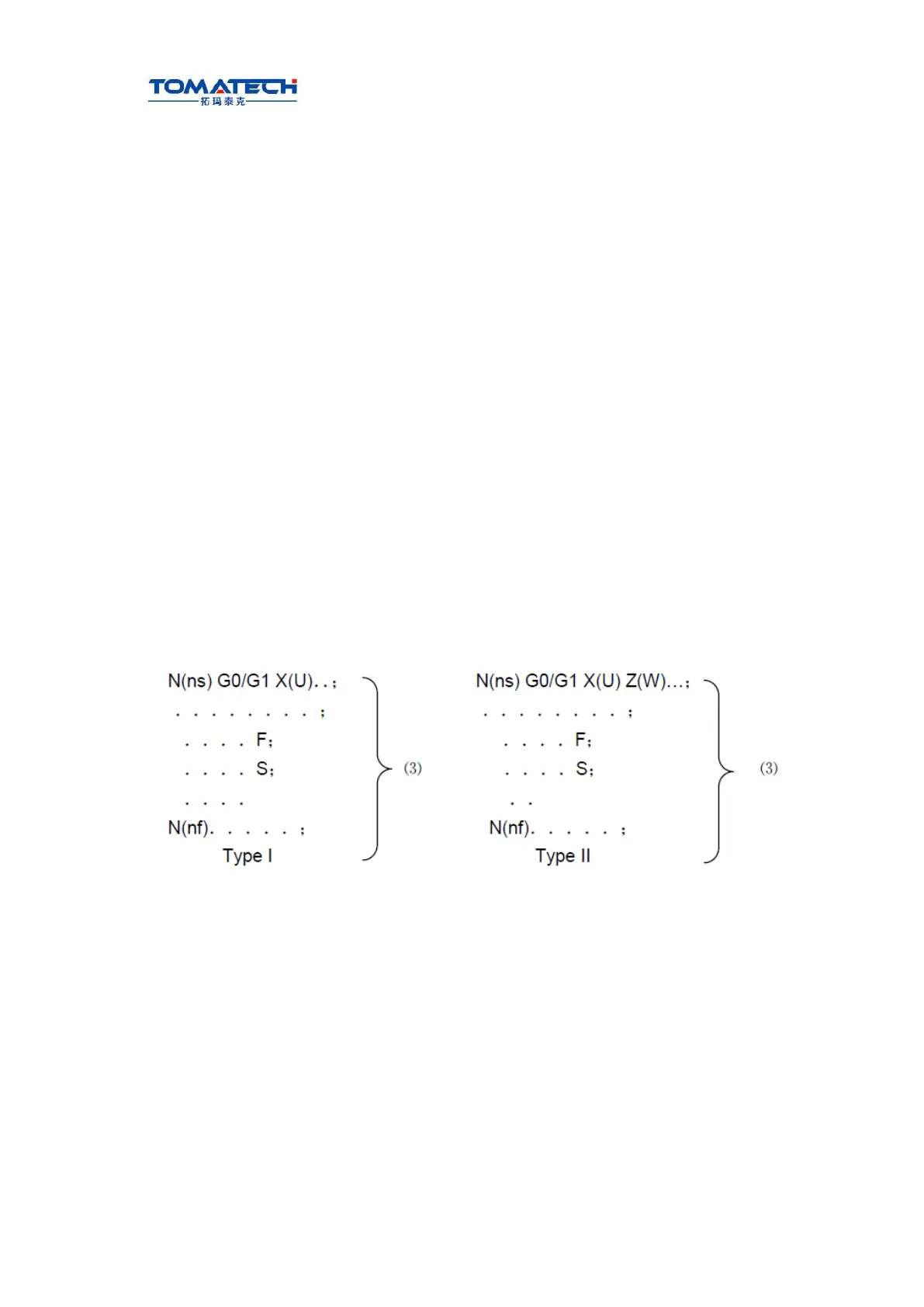

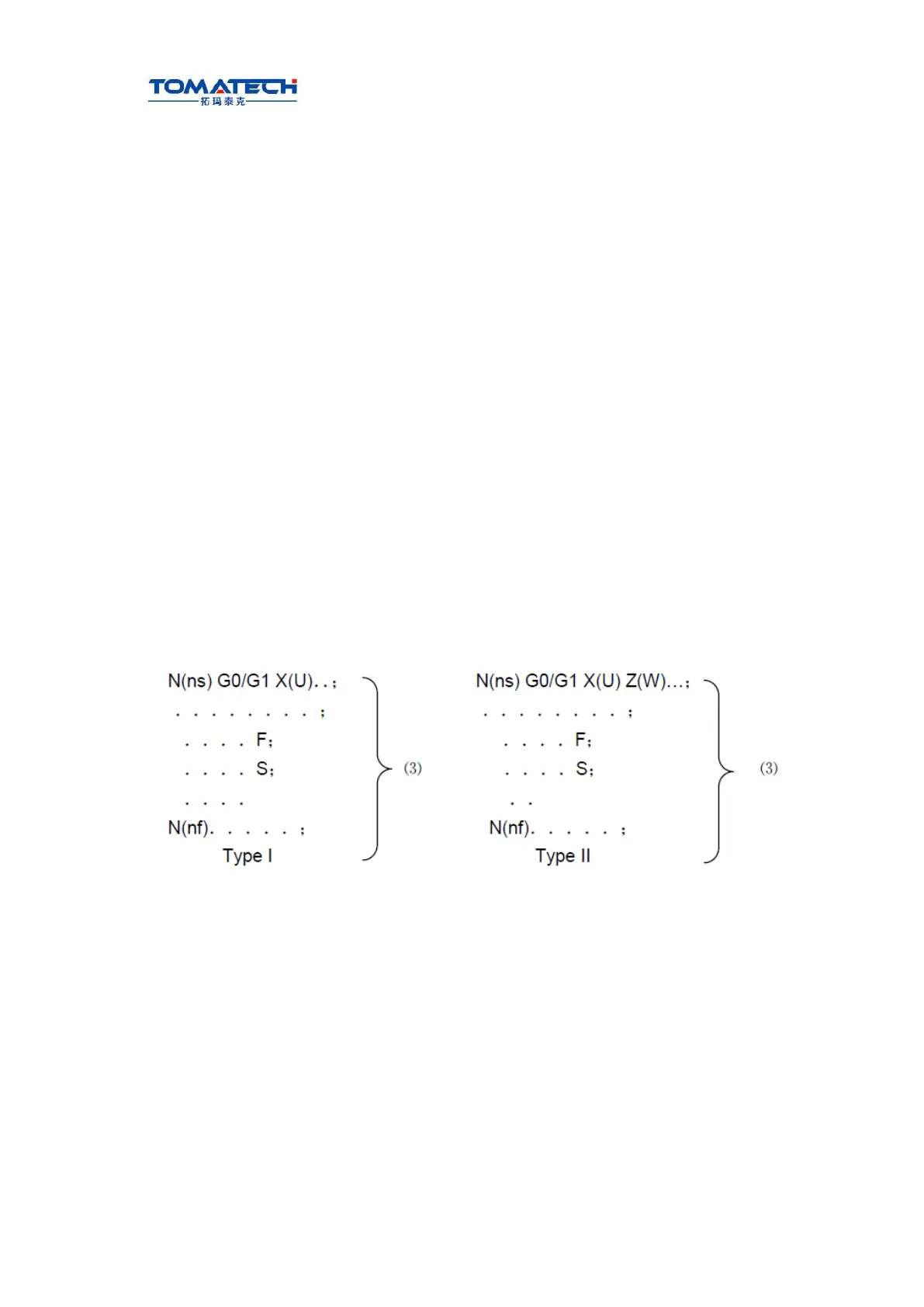

G71 has two kinds of roughing cycle: type I and type II.

Command format:G71 U(Δd) R(e) F S T ;⑴

G71 P(ns) Q(nf) U(Δu) W(Δw) K0/1 J0/1;⑵

Command function: G71 is divided into three parts:

⑴ 1st blocks for defining the travels of tool infeed and retract tool, the cutting feedrate,

the spindle speed and the tool function when roughing;

⑵ 2nd blocks for defining the block interval, finishing allowance;

⑶ 3rd blocks for some continuous finishing path, counting the roughing path without

being executed actually when executing G71.

According to the finishing path, the finishing allowance, the path of tool infeed and tool

retract,

the system automatically counts the path of roughing, the tool cuts the workpiece in

paralleling with Z,

and the roughing is completed by multiple executing the cutting cycle tool

infeed→cutting→tool

retraction. The starting point and the end point are the same one. The command is applied

Loading...

Loading...