TOMATECH AUTOMATION

program,

which is called the compound programming.

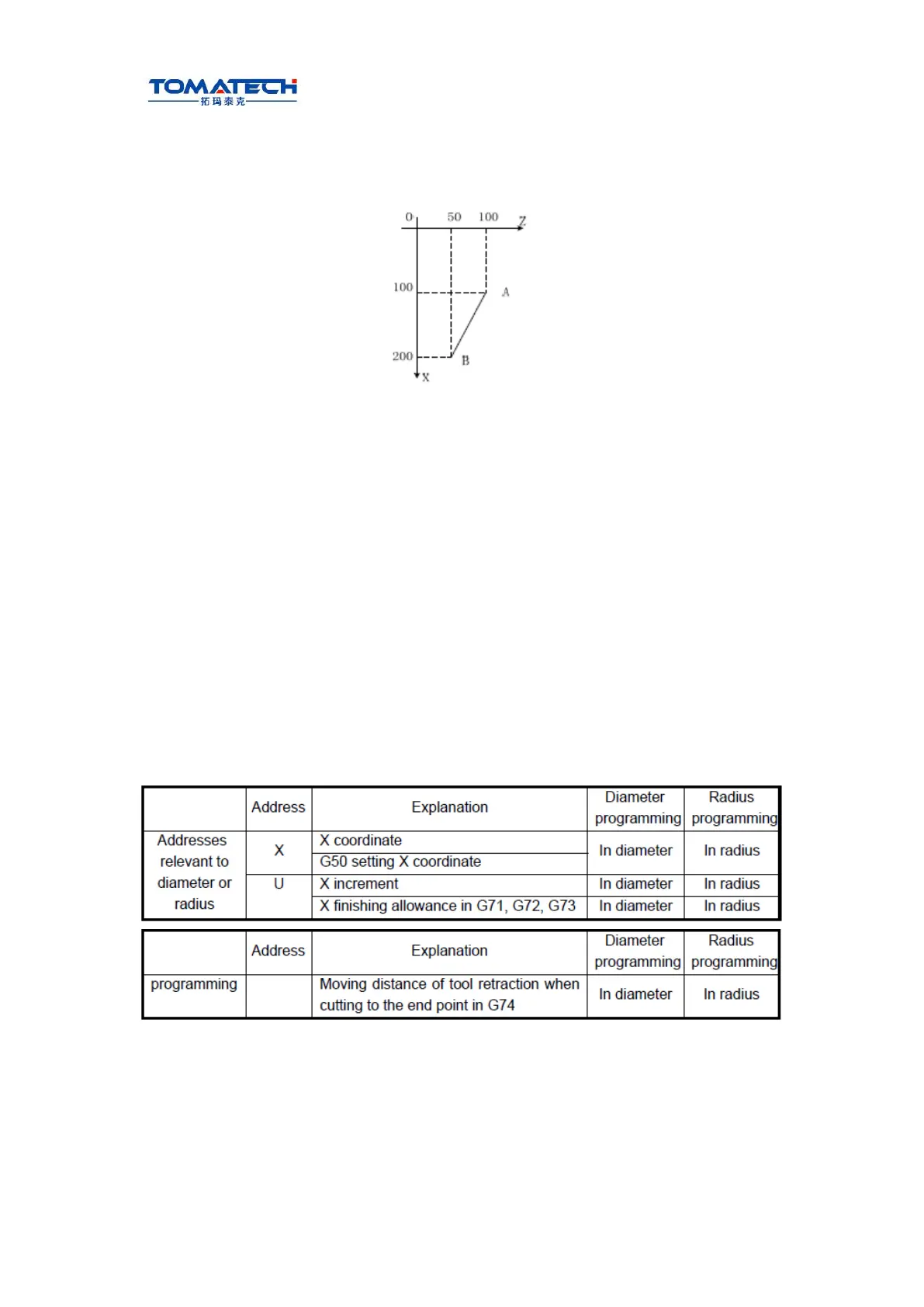

Example: A→B linear interpolation

Fig.1-8

Absolute programming: G01 X200 Z50;

Incremental programming: G01 U100 W-50;

Compound programming: G01 X200 W-50; or G01 U100 Z50

Note: When there are command address X/ U or Z/ W at the same time, X/Z command value is

valid.

Example: G50 X10 Z20;

G01 X20 W30 U20 Z30; 【End point of the block (X20, Z30)】

1.3.6 Diameter programming and radius programming

Programming methods of X coordinate values are divided into: diameter programming

and radius programming.

Diameter programming: when NO.001 Bit2 is 0, X input command value is in diameter and

X coordinate is in diameter at the moment;

Radius programming: when NO.001 Bit2 is 1, X input command value is in radius and X

coordinate is in radius at the moment.

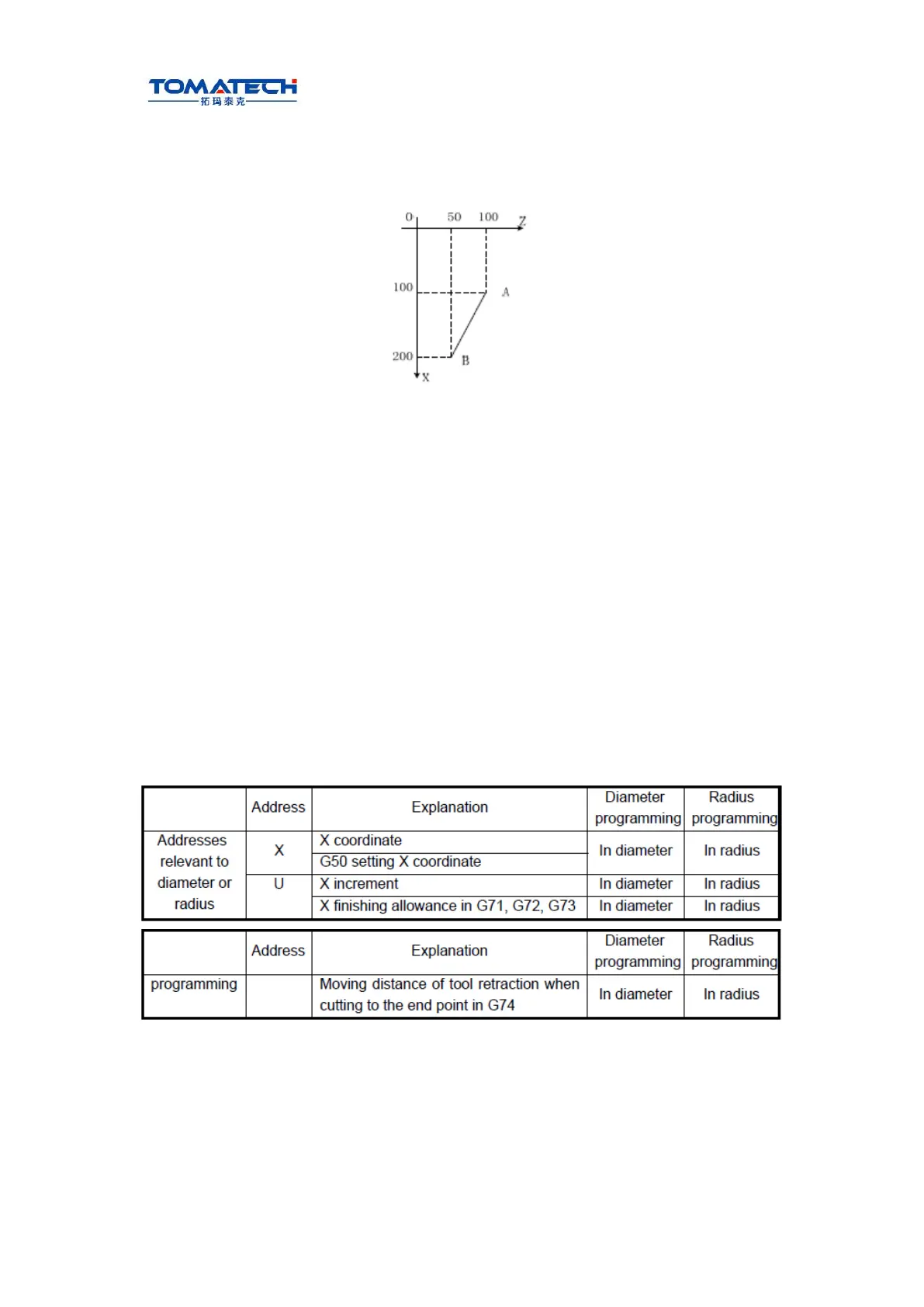

Addresses relevant to diameter or radius programming

Except for addresses and data in Table 1-1, others (arc radius, taper in G90) are

unrelated to diameter or radius programming, and their input values in X direction are

defined by the radius.

Note: The diameter programming is used except for the special description in the following

explanation.

1.4 Structure of an NC Program

Loading...

Loading...