TOMATECH AUTOMATION

G32 X50 W-75 F2.0; (Second taper thread cutting )

G00 X55; (Tool retraction)

W75 ; (Z returns to the starting point)

M30;

3.21.3 Thread cutting with variable lead G34

Command format:G34 X(U)__ Z(W)__ F(I)__ J__ K__ R__ ;

Command function: The motion path of tool is a straight line from starting point of X, Z to

end point specified by the block, the longer moving distance from starting point

to end point(X in radius value) is called as the long axis and another is called as the short

axis. In course of motion, the long axis traverses one lead when the spindle rotates one

rev, the pitch increases or decreases a specified value per rev and one spiral grooving

with variable lead on the surface of workpiece to realize thread cutting with variable lead.

Tool retraction can be set in thread cutting.

F, I are specified separately to metric, inch pitch. Executing G34 can machine metric or

inch straight, taper, end face thread with variable pitch.

Command specifications:

G34 is modal;

Meanings of X(U) , Z(W) , J, K are the same that of G32;

F: Specify lead, and its range is referred to Table 1-2;

I: Specify thread teeth per inch, and its range is referred to Table 1-2;

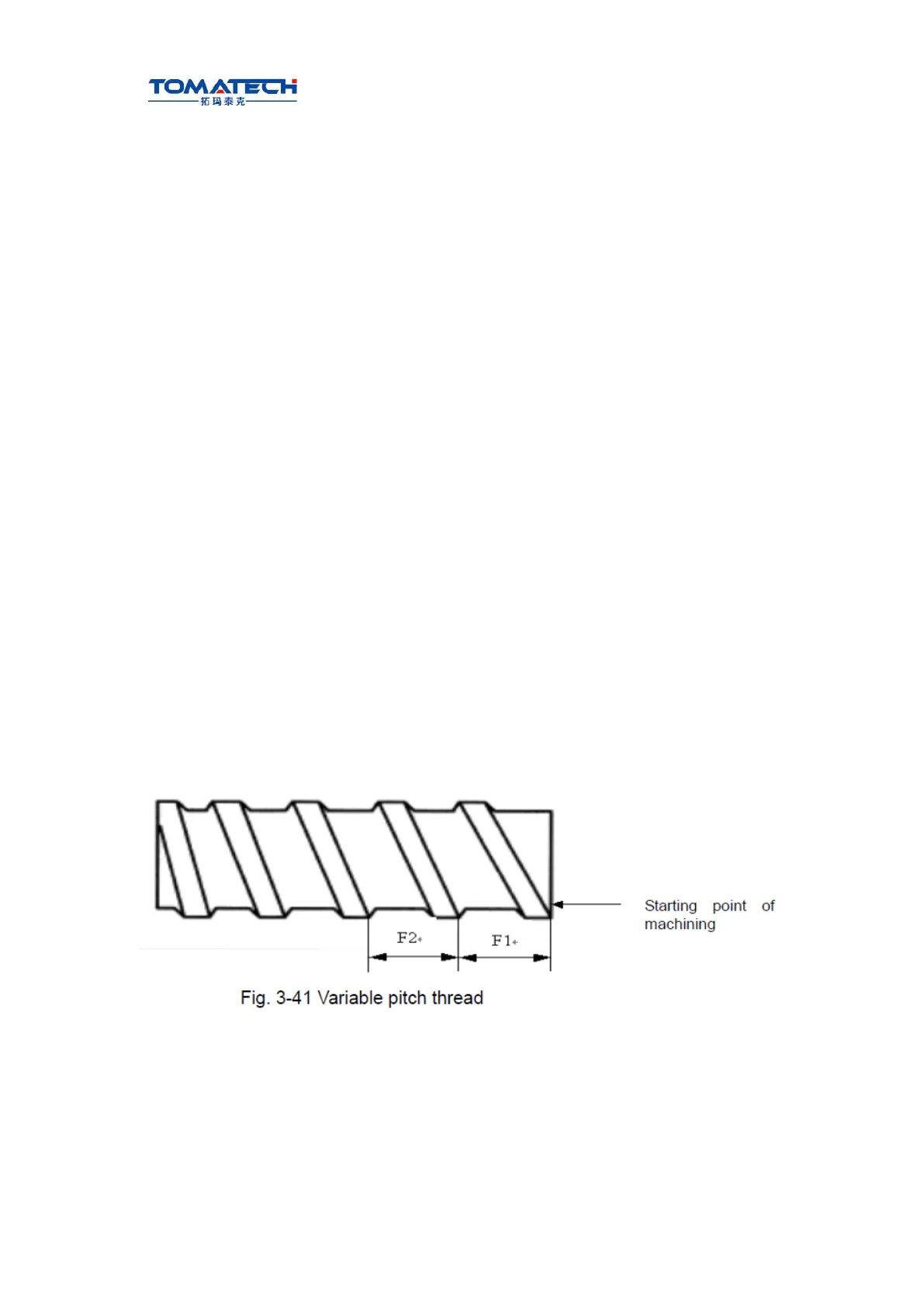

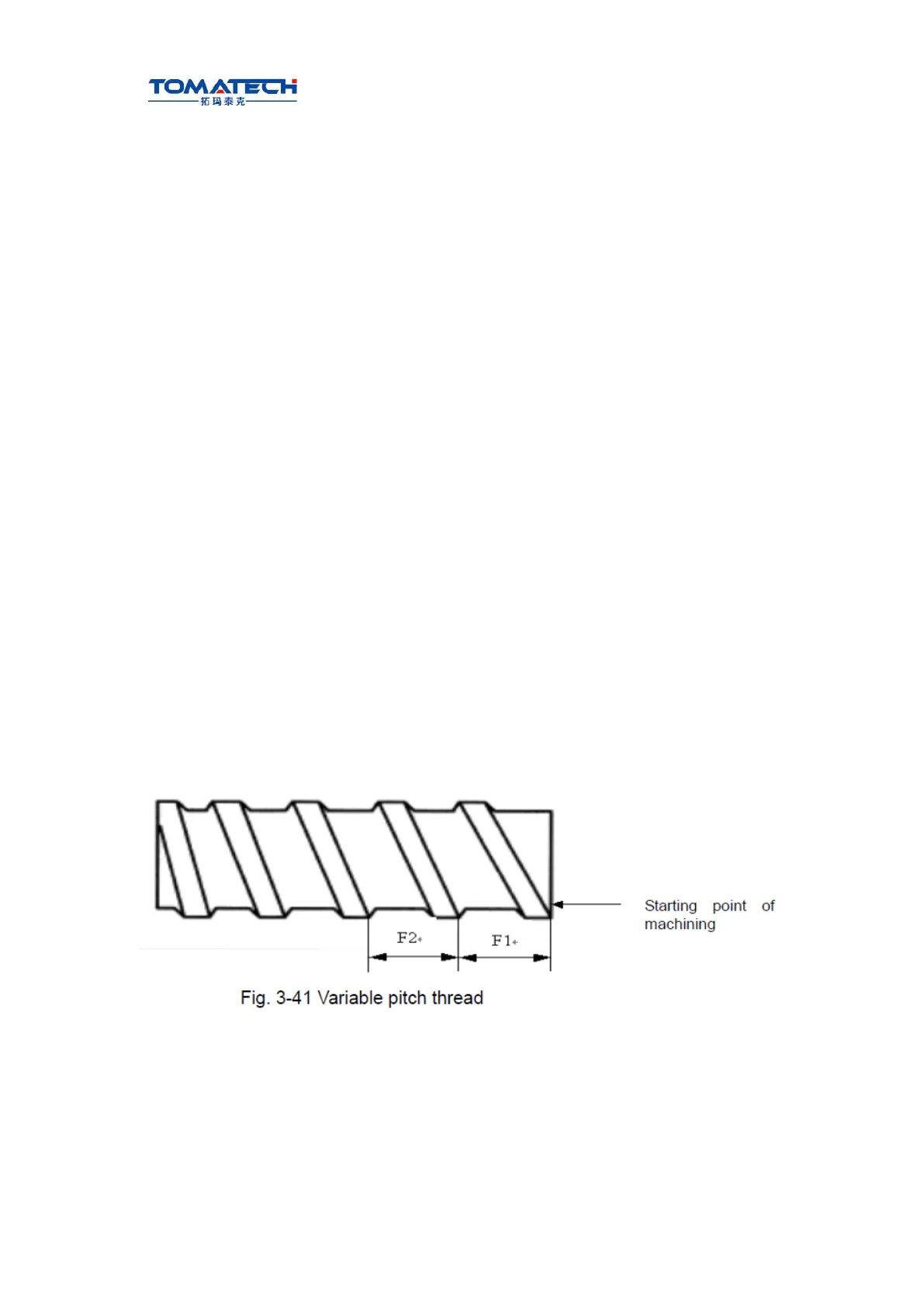

R: Increment or decrement of pitch per rev, R=F1- F2, with direction; F1>F2, pitch

decreases when R is negative; F1<F2, pitch increases when R is positive (as Fig. 3-41);

R: ±0.001~±500.000 mm/pitch (metric thread);

±0.060~±25400 tooth/inch (inch thread).

The system alarms when R exceeds the above-mentioned range or the pitch exceeds

permissive value or is negative owing to R increases or decreases.

Note: It is the same as that of G32.

Example: First pitch of starting point: 4mm, increment 0.2mm per rev of spindle.

Loading...

Loading...