TOMATECH AUTOMATION

CHAPTER 2 MSTF COMMAND

2.1 M (Miscellaneous Function)

M command consists of command address M and its following 1~2 or 4 bit digits, used

for

controlling the flow of executed program or outputting M commands to PLC.

M98, M99, M9000~M9999 is executed by NC separately and NC does not output M

commands to PLC.

M02, M03 are for ending of programs defined by NC, and NC outputs M commands to

PLC which can control spindle OFF, cooling OFF and so on.

M98, M99, M9000~M9999 are for calling programs, M02, M30 are for ending of program

which are not changed by PLC. Other M commands output to PLC and their function are

defined by PLC.

Please refer to User Manual from machine manufacturer.

There is only one M command in one block, otherwise the system alarms.

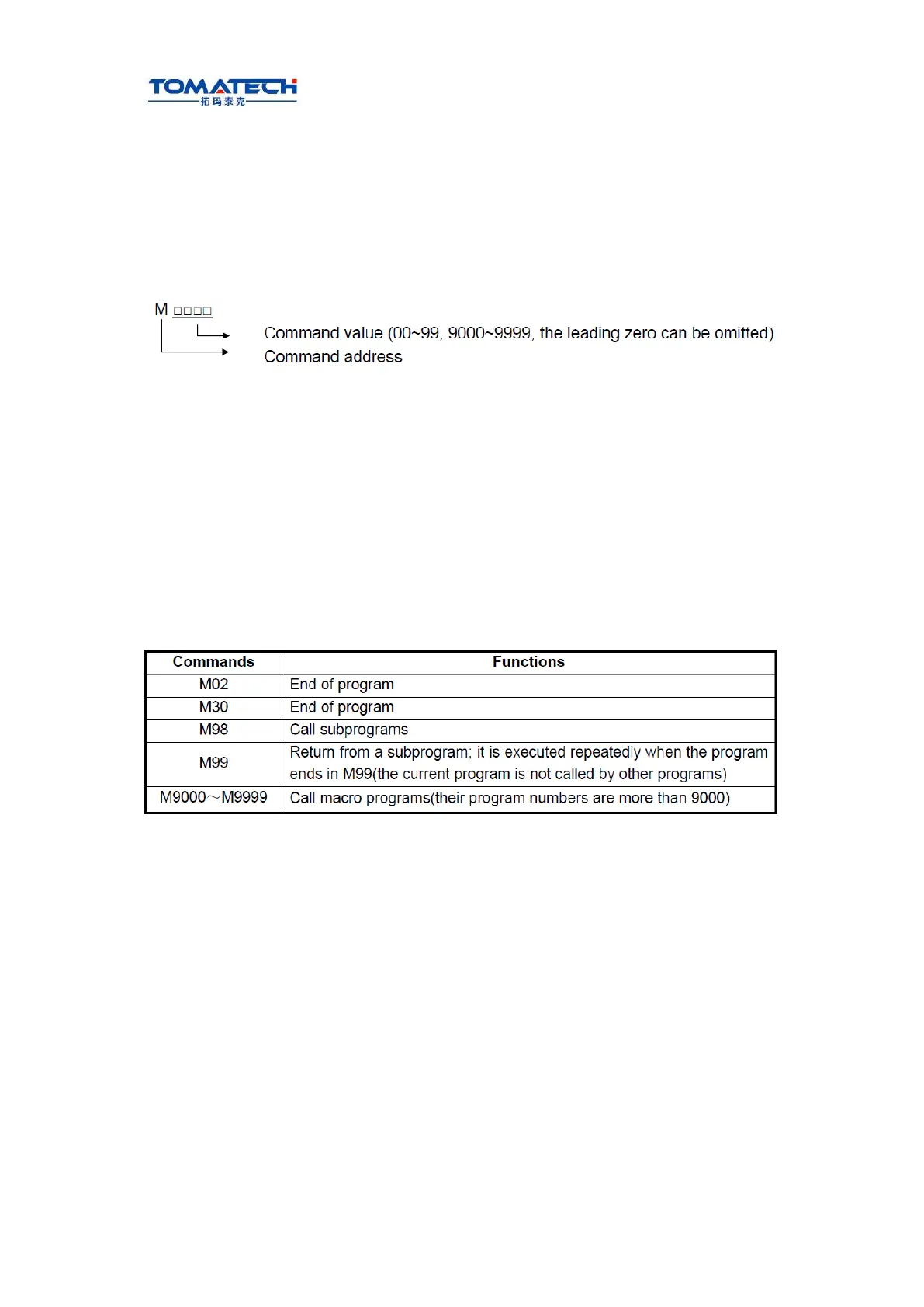

Table 2-1 M commands to control program execution

Commands Functions

End of program M02

Command format: M02 or M2

Command function: In Auto mode, after other commands of current block are executed,

the

automatic run stops, and the cursor stops a block in M02 and does not

return to the start of program. The cursor must return to the start of program

when the program is executed again.

Besides the above-mentioned function executed by NC, M02 function is also defined by

PLC ladder diagram as follows: current output of CNC is reserved after M02 is executed.

End of program run M30

Command format: M30

Command function: In Auto mode, after other commands of current block are executed in

M30,

the automatic run stops, the amount of workpiece is added 1, the tool nose

radius compensation is cancelled and the cursor returns to the start of

Loading...

Loading...