TOMATECH AUTOMATION

Fig. 3-38 G32 path

Notes:

● J, K are modal. The thread run-out is previous J, K value when they are omitted in the

next block in continuous thread cutting. Their mode are cancelled when no thread cutting

are executed;

● There is no thread run-out when J, or J, K are omitted; K=J is the thread run-out value

when K is omitted;

● There is no thread run-out when J=0 or J=0, K=0;

● The thread run-out value J=K when J≠0,K=0;

● There is no thread run-out when J=0 or K≠0;

● If the current block is for thread and the next block is the same, the system does not

test the spindle encoder signal per rev at starting the next block to execute the direct

thread cutting,which function is called as continuous thread machining;

● After the feed hold is executed, the system displays “Pause” and the thread cutting

continuously executes not to stop until the current block is executed completely; if the

continuous thread cutting is executed, the program run pauses after thread cutting blocks

are executed completely;

● In Single block, the program stops run after the current block is executed. The program

stops running after all blocks for thread cutting are executed;

● The thread cutting decelerates to stop when the system resets, emergently stop or its

drive unit alarms.

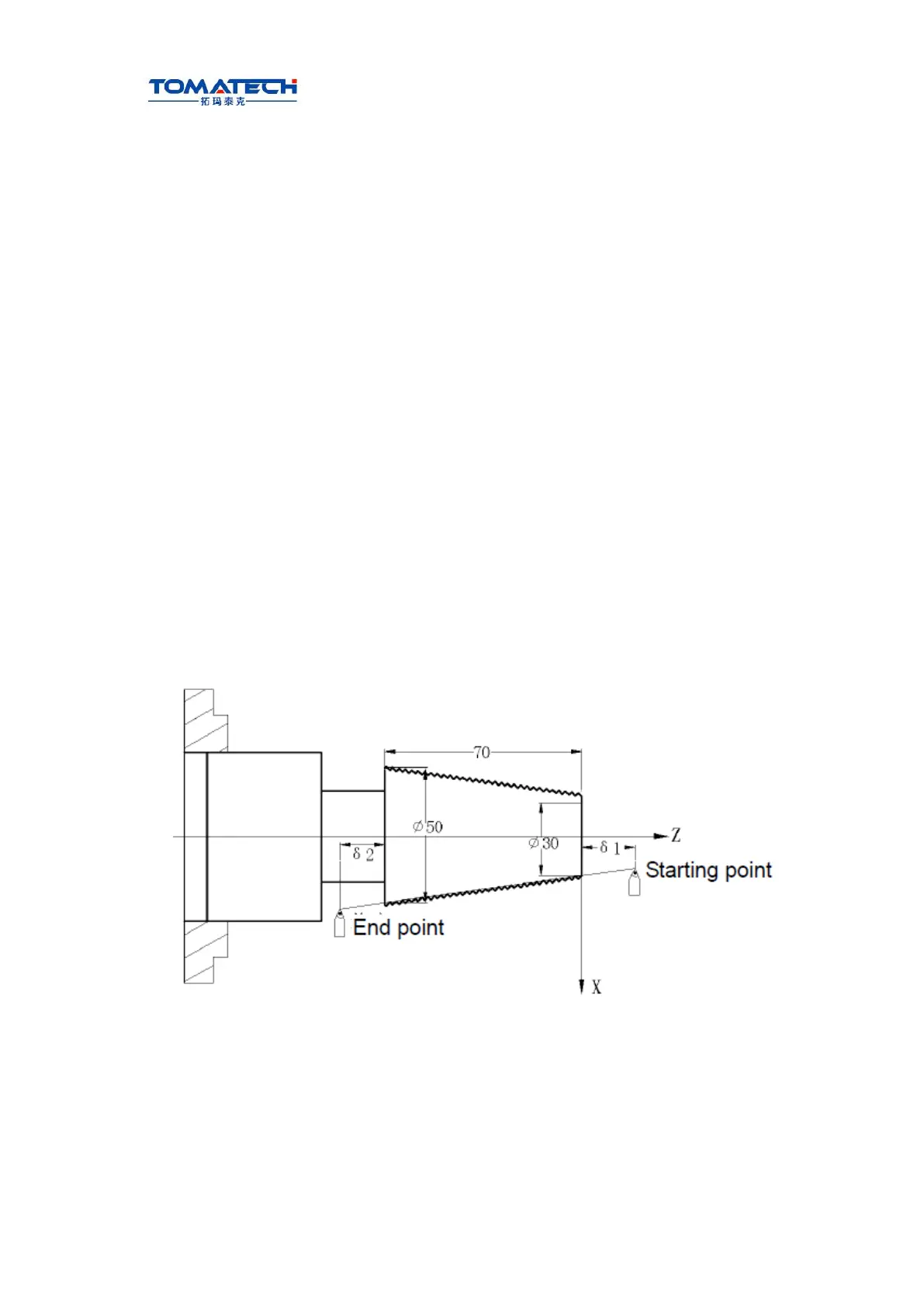

Example: Pitch: 2mm. δ1 = 3mm,δ2 = 2mm,total cutting depth 2mm divided into two

times cut-in.

Fig-3-39

Program:

O0009;

G00 X28 Z3; (First cut-in 1mm)

G32 X51 W-75 F2.0; (First taper cutting)

G00 X55; (Tool retraction)

W75; (Z returns to the starting point)

X27; (Second tool infeed 0.5mm)

Loading...

Loading...