TOMATECH AUTOMATION

Execute the end face thread cutting when X coordinates of starting point and end point

are the same one(not input Z or W);

Execute the cutting taper thread when X and Z coordinates of starting point and end point

are different;

Related definitions:

F: Metric pitch is moving distance of long axis when the spindle rotates one rev: 0.001

mm~500mm. After F is executed, it is valid until F with specified pitch is executed again.

I: Teeth per inch. It is ones per inch(25.4 mm) in long axis, and also is circles of spindle

rotation when the long axis traverses one inch(25.4 mm) :0.06tooth/inch~

25400tooth/inch. After I is executed, it is valid until I with specified pitch is executed again.

The metric, inch input both express the teeth per inch thread.

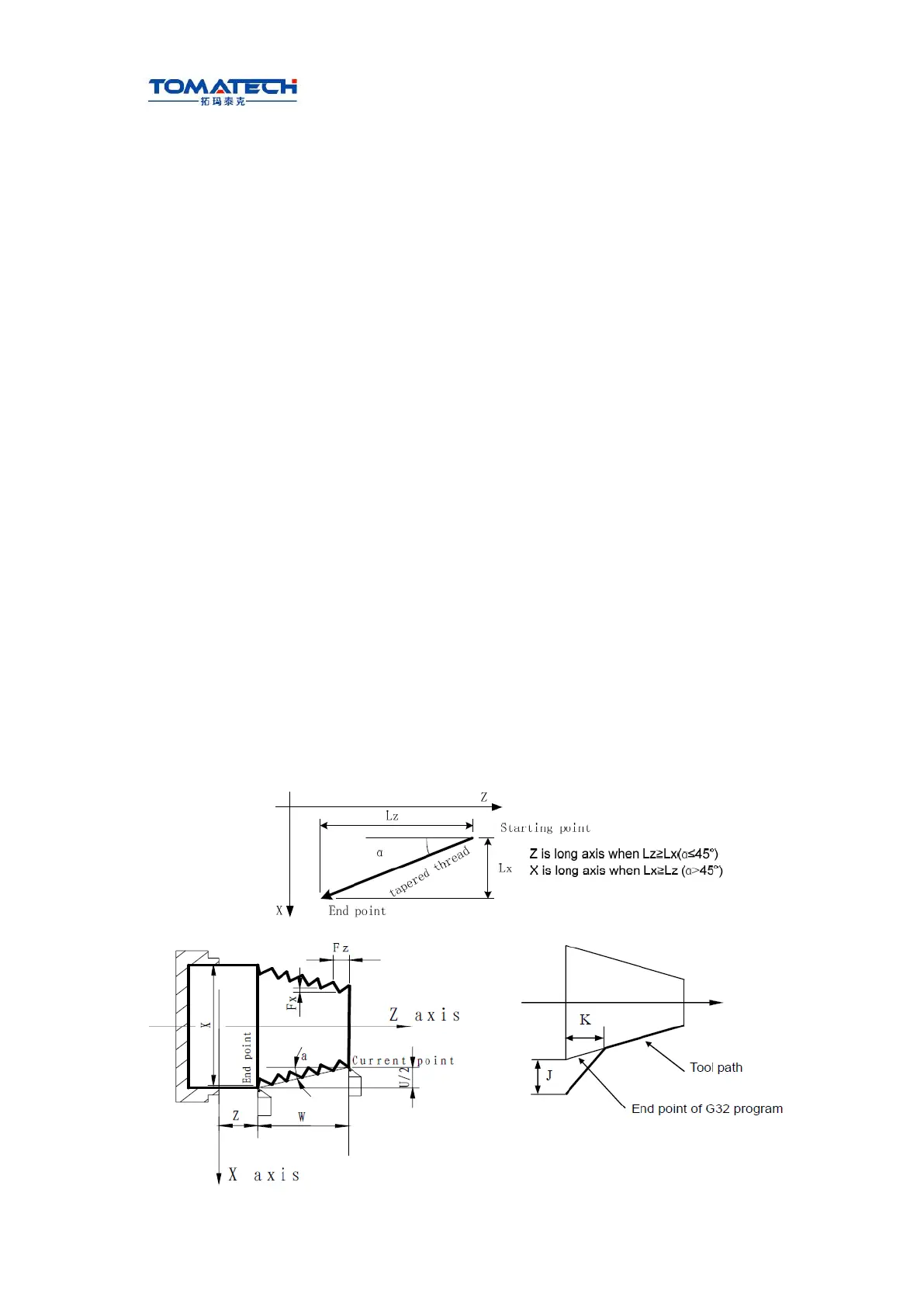

J: Movement in the short axis in thread run-out, its range: ±99999999× least input

increment with negative sign; if the short axis is X, its value is specified with the radius; J

value is the modal parameter.

K: Length in the long axis in thread run-out, its range: ±99999999× least input increment.

If the long axis is X, its value is in radius without direction; K is modal parameter.

Q: Initial angle(offset angle)between spindle rotation one rev and starting point of thread

cutting: 0~360000 (unit: 0.001 degree). Q is non-modal parameter, must be defined

every time,otherwise it is 00.rogramming

Q rules:

1. Its initial angle is 0° if Q is not specified;

2. For continuous thread cutting, Q specified by its following thread cutting block except

for the first block is invalid, namely Q is omitted even if it is specified;

3. Multi threads formed by initial angle is not more than 65535;

4. Q unit : 0.0010 . Q180000 is input in program if it offsets 1800 with spindle one-turn; if

Q180 or Q180.0, it is 0.18°.

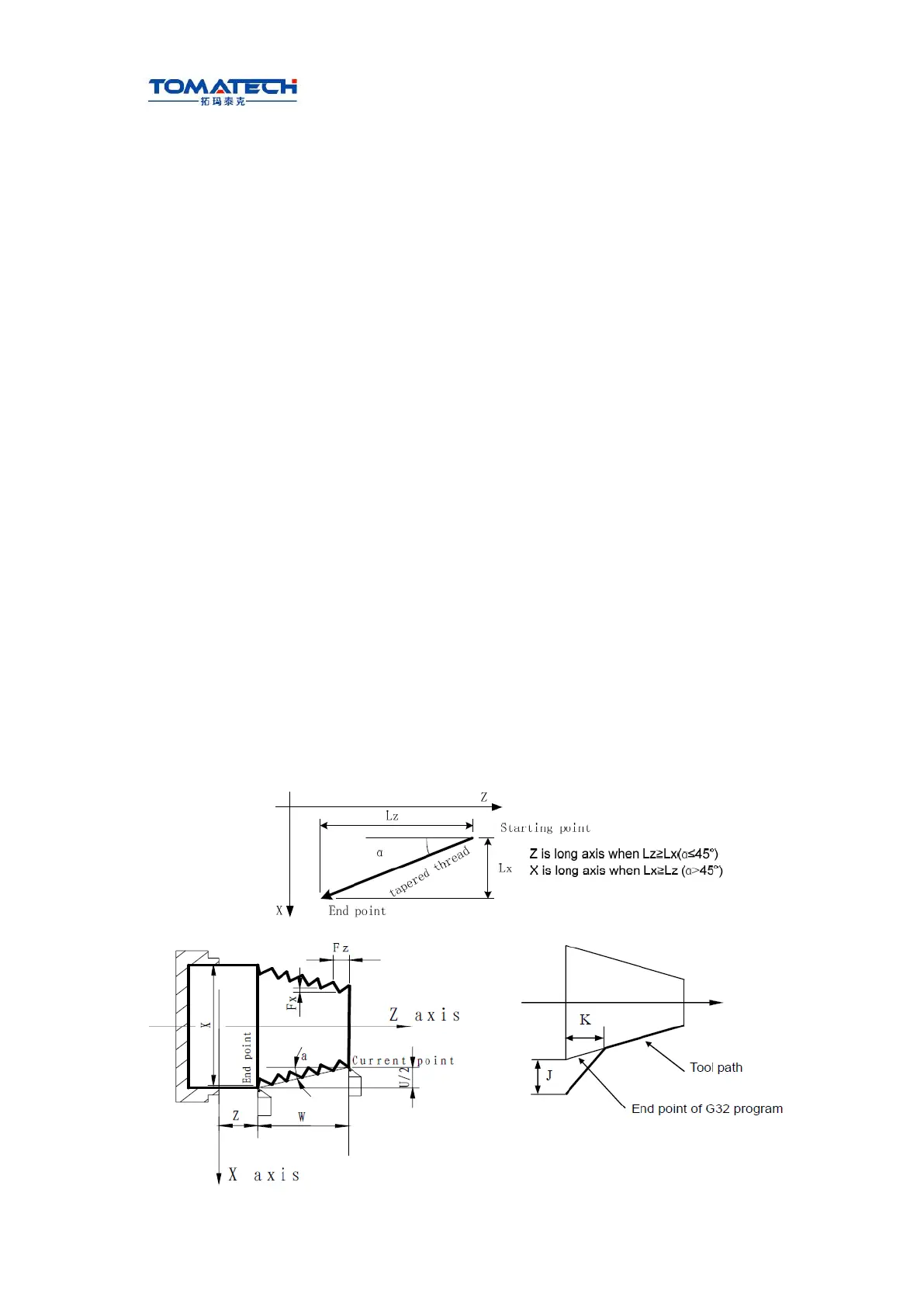

Difference between long axis and short axis is shown in Fig. 3-38.

Loading...

Loading...