TOMATECH AUTOMATION

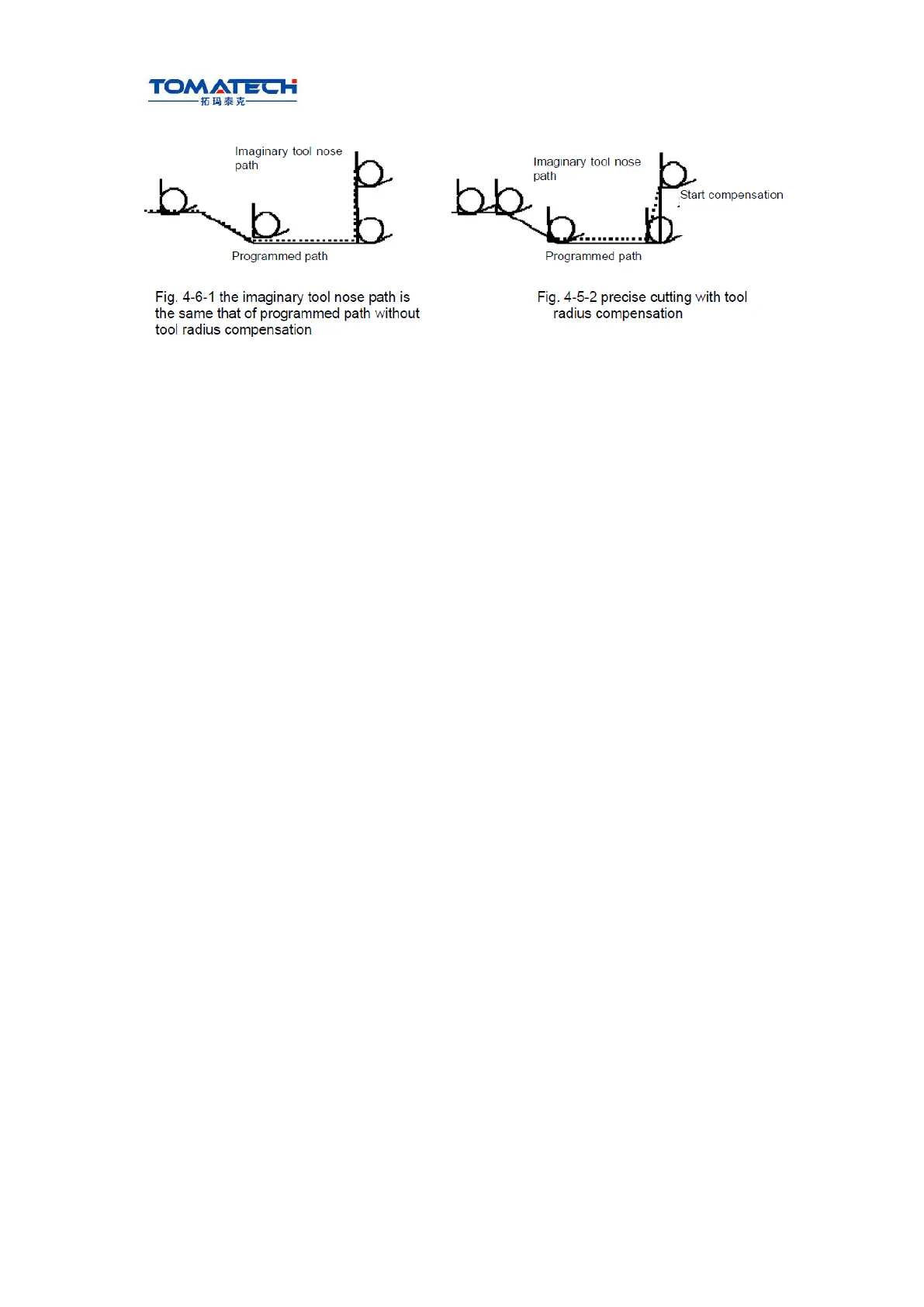

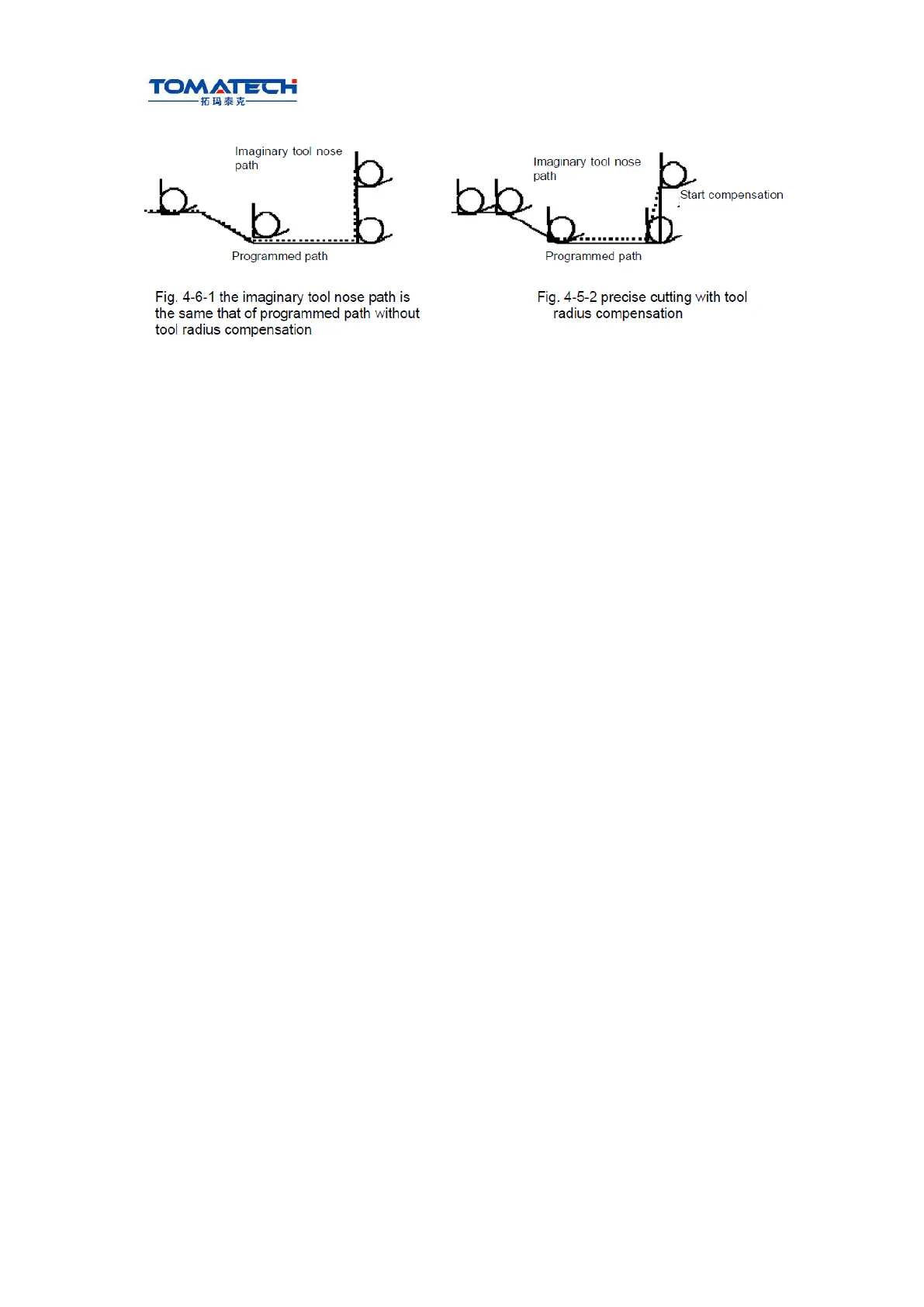

The tool is supposed to one point in programming but the actual cutting blade is not one

ideal point owing to machining technology. Because the cutting blade is not one point but

one circular,

machining error is caused which can be deleted by tool nose circular radius compensation.

In actual machining, suppose that there are different position relationship between tool

nose point and tool nose circular center point, and so it must create correct its direction of

imaginary tool nose.

From tool nose center to imaginary tool nose, set imaginary tool nose numbers according

to tool direction in cutting. Suppose there are 10 kinds of tool nose setting and 9 directions

for position relationship. The tool nose directions are different in different coordinate

system (rear tool post coordinate system and front tool post coordinate system) even if

they are the same tool nose direction numbers as the following figures. In figures, it

represents relationships between tool nose and starting point, and end point of arrowhead

is the imaginary tool nose; T1~T8 in rear tool post coordinate system is as Fig. 4-7; T1~

T8 in front tool post coordinate system is as Fig. 4-8.

The tool nose center and starting point for T0 and T9 are shown in Fig. 4-9.

Ⅰ

Programming

Loading...

Loading...