TOMATECH AUTOMATION

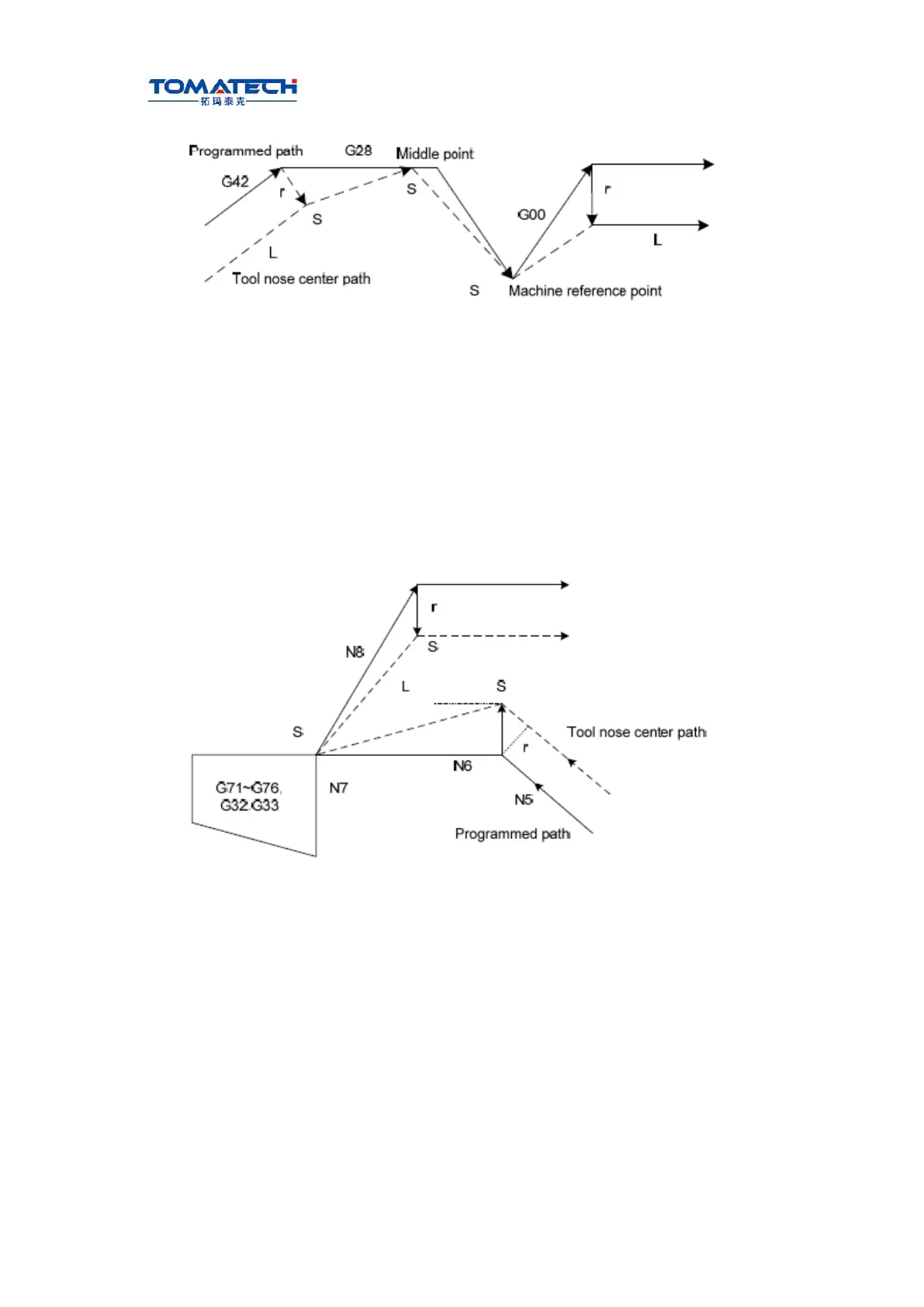

Fig. 4-20 Cancel compensation vector temporarily in G28

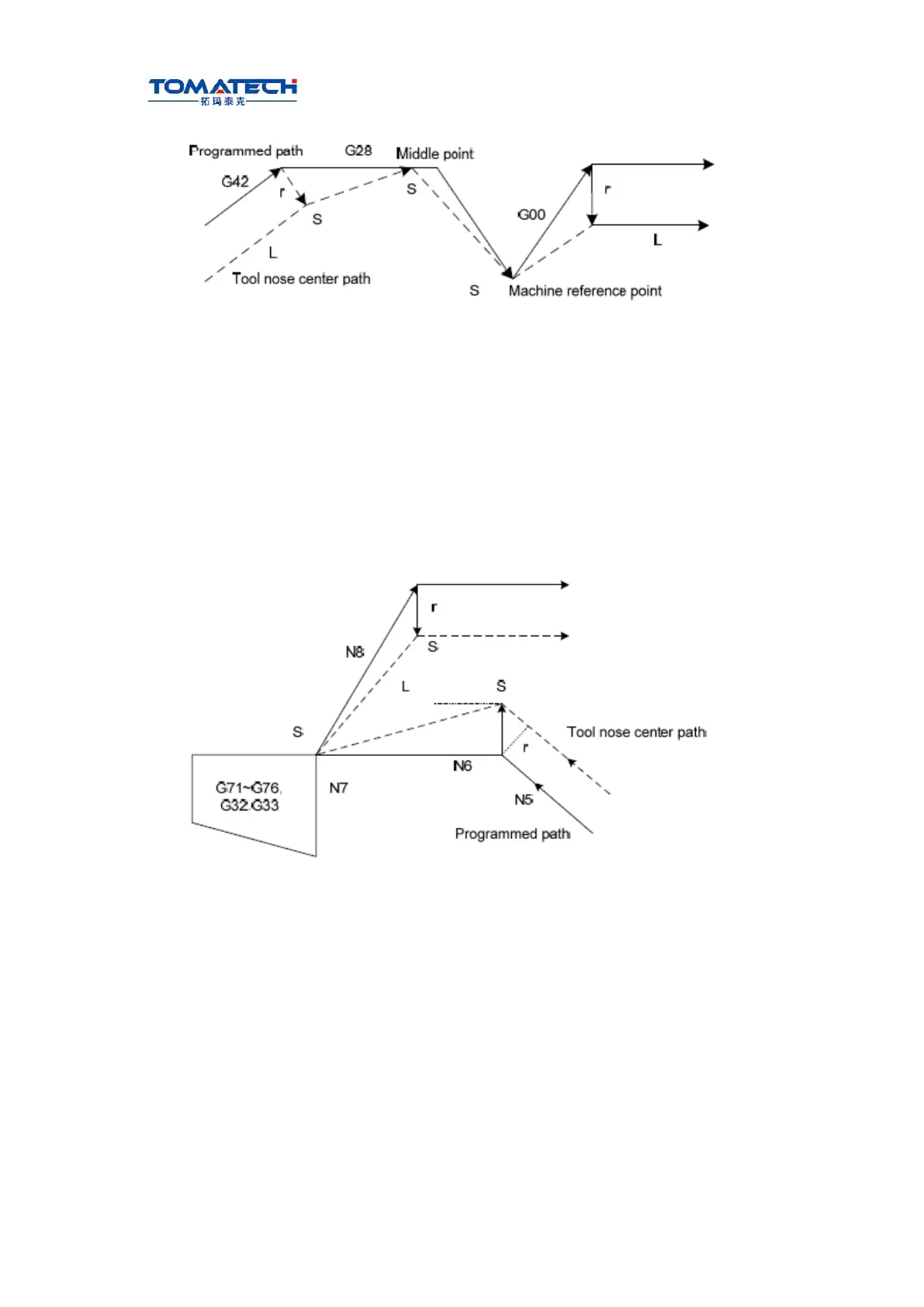

� G71~G75 compound cycle; G76, G92 thread cutting

When executing G71~G76 , G96 thread cutting, the system does not execute the tool

nose radius compensation and cancel it temporarily, and there is G00, G01,in the

following blocks, and the system automatically recovers the compensation mode.

� G32, G33,G34 thread cutting

They cannot run in the tool nose radius compensation mode, otherwise, No.131 alarm

occurs

“……CANNOT USED TO C COMPENSATION”.

Fig. 4-21 Cancel compensation vector temporarily in G71~G76

� G32, G33, G34 constant thread cutting

They cannot be executed in tool nose radius compensation mode, otherwise, No. 131

alarm occurs “……the command cannot be used in C compensation mode.”

� G90, G94 (taking an example of G42)

Compensation method of tool nose radius compensation in G90 or G94:

A. Cancel the previous tool nose radius compensation;

B. Create the previous C compensation before cutting, and the path ① in the following

figure creates the previous radius compensation mode;

C. The paths 2, 3 in the following figure are the radius compensation cutting;

D. The path 4 in the following figure can cancel the radius compensation, and the tool

returns to the cycle starting point; there is G00,G01 in the following block, and the CNC

automatically recovers the compensation mode.

Loading...

Loading...