892-0000010B OM

240

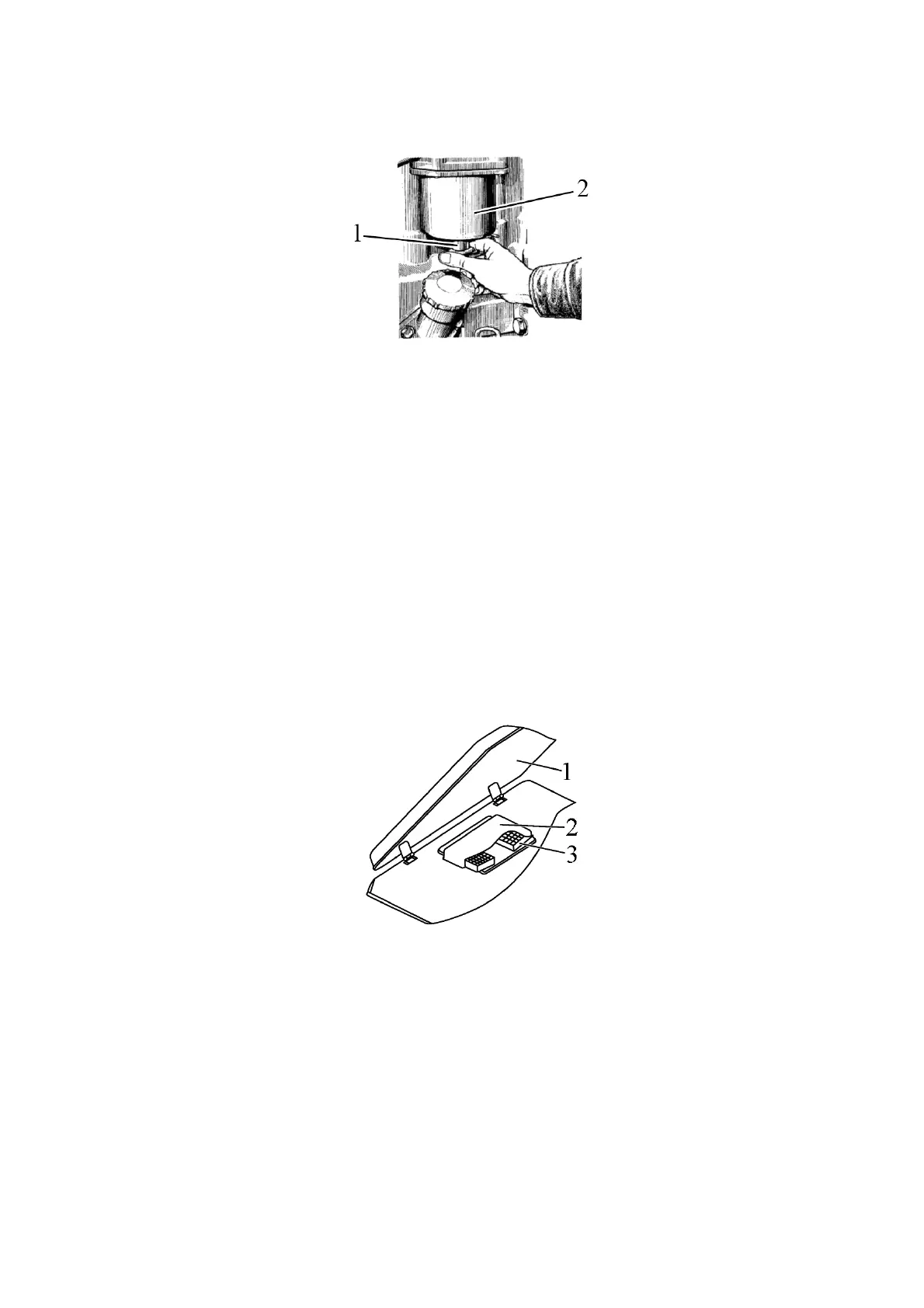

- drain the sediment until the clean fuel appears, collect sediment in special container;

- after appearing of clean fuel without water and drain, close drain plug 1.

1 – drain plug of coarse fuel filter; 2 – coarse fuel filter.

Figure 6.4.11 – Drain of sediment from coarse fuel filter

6.4.2.11 Operation 19. Cleaning of filter cartridges of the filter for cab ventilation and

heating system

To clean the filter for cab ventilation and heating system, do the following:

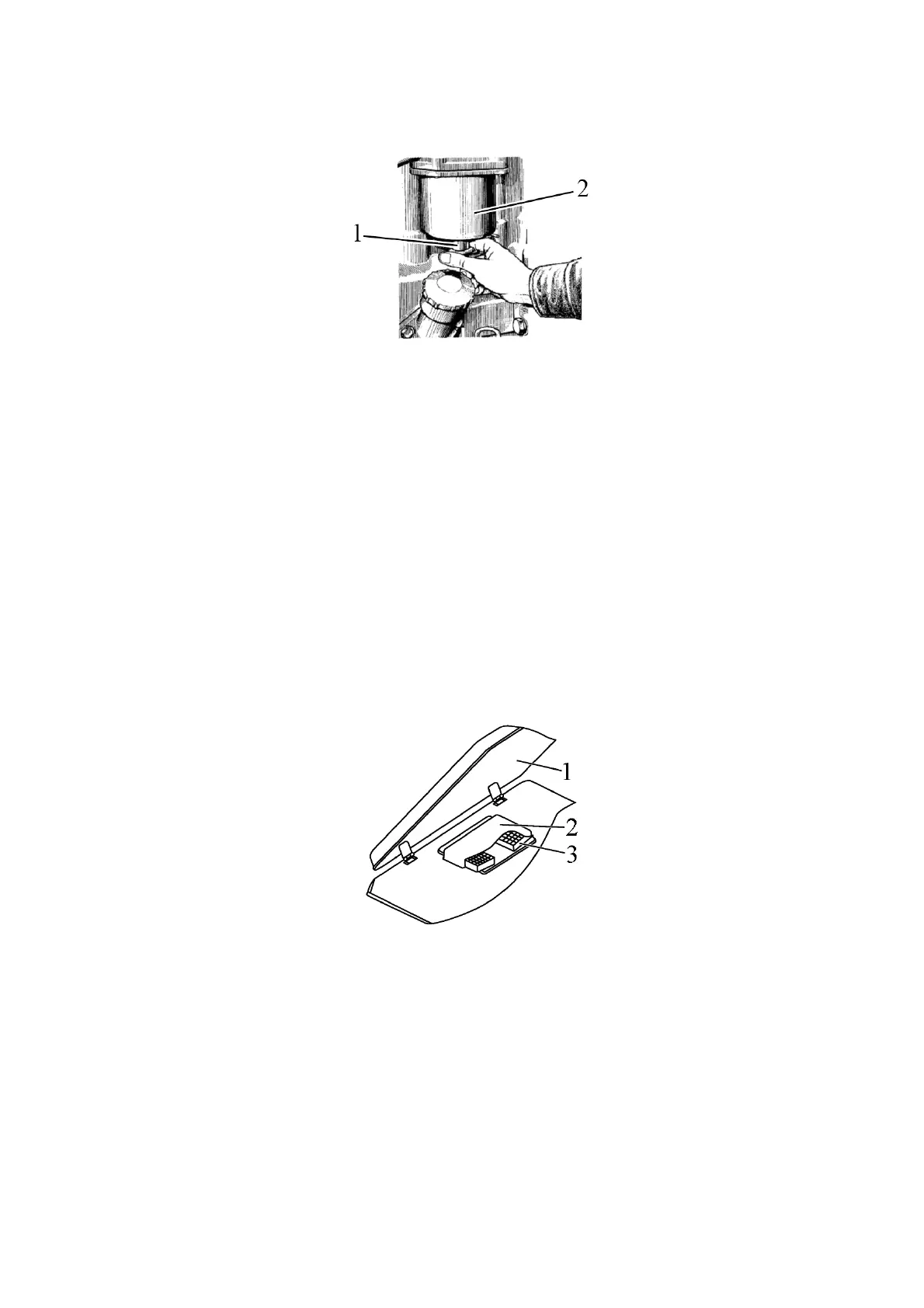

- lift the cab roof 1 (Figure 6.4.12).

- undo two fastening bolts and remove the filter cover 2 together with two filter

cartridges 3.

- slightly shake the components to remove free dust particles from the filter; be careful

not to damage the filter.

- clean filters with compressed air under pressure of max 0.2 MPa. Keep the hose head

at a distance of min. 300 mm from the filter in order not to damage the paper filtering

cartridge. Direct an air flow through the filter in the direction that is opposite the regular air

flow, which is indicated with arrows marked on the filter.

- re-install the filter by performing operations in reverse order, and close the cab roof.

1 – cab roof; 2 – filter cover; 3 – filter cartridge.

Figure 6.4.12 – Cleaning of filter for cab ventilation and heating system

ATTENTION: DO NOT SWITCH ON THE FAN BEFORE CLEANING THE FILTERS AT

HIGH HUMIDITY OF THE ENVIRONMENT, FOR EXAMPLE IN THE MORNING, AS IT IS DIF-

FICULT TO REMOVE MOISTURE PARTICLES FROM FILTER CARTRIDGE!

ATTENTION: DURING TRACTOR OPERATION IN HEAVY DUSTING CONDI-

TIONS, CLEAN THE FILTER EVERY 8-10 HOURS OF OPERATION, I.E. ON A SHIFT

BASIS!

6.4.2.12 Operation 20. Condition/tension check of fan drive belt of engine cooling

system

The tension of fan drive belt is considered to be normal if deflection of its branch from

the engine crankshaft pulley to the alternator pulley as in Figure 6.4.13 is 12 to 17 mm for

engine D-245.5 (D-245.5C) when a force of 40 N is applied to it.

Loading...

Loading...