892-0000010B OM

239

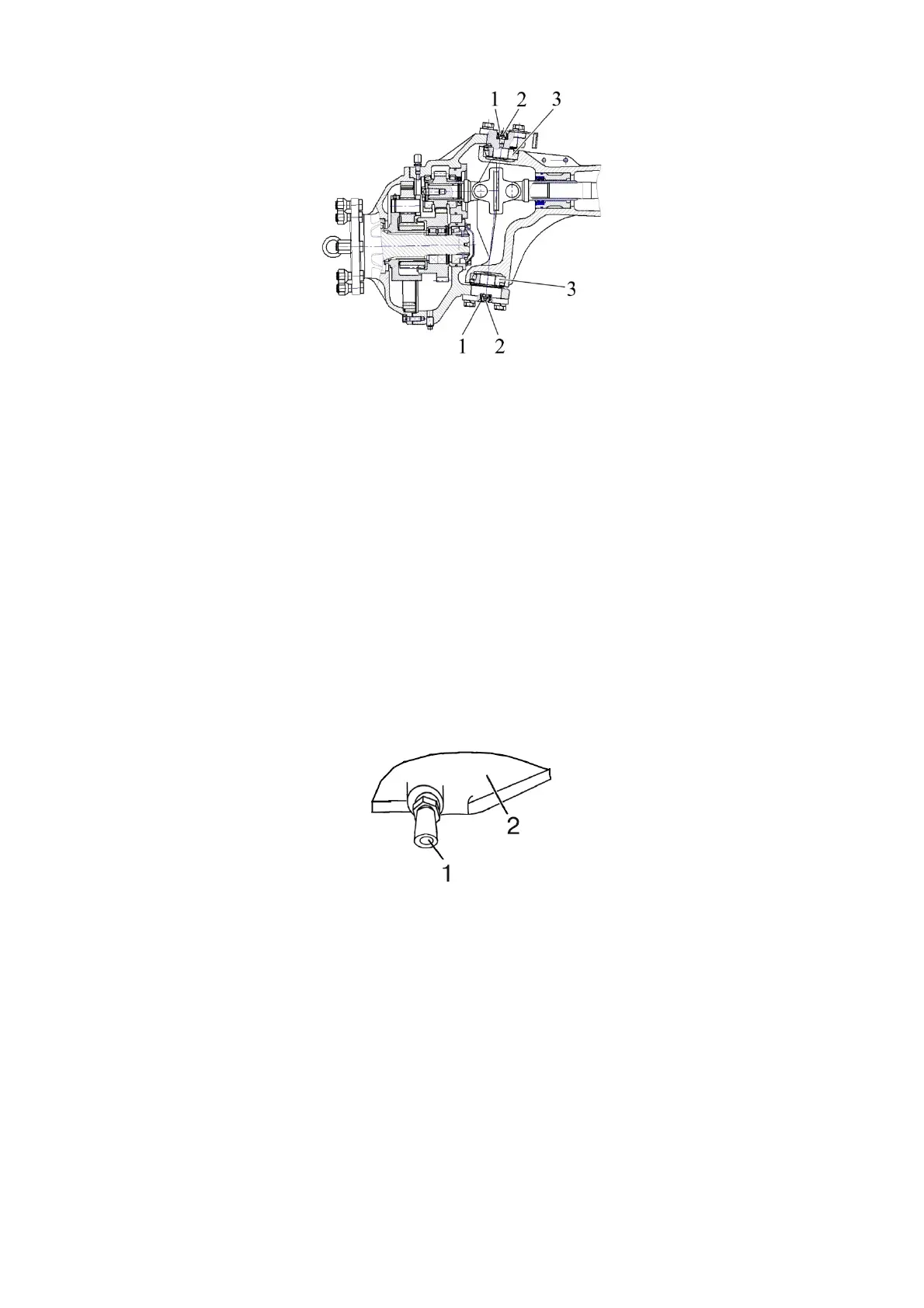

1 – cap, 2 – greasers; 3 – bearing.

Figure 5.4.13 – Lubricating FDA pivot bearings

6.4.2.8 Operation 16. Check of pneumatic pressure in tires

Pressure in the front and rear tires is determined from load per single tire, driving speed

and operations performed. If it is necessary bring the pressure up to the required value in

compliance with subsection 3.2.8 “Selection of optimal internal pressure in tires, depending

on the operating conditions and load on the tractor axles”.

ATTENTION: CONTROL AND BRINGING THE TIRES INTERNAL PRESSURE UP TO

THE NORMAL VALUE, WHEN NEEDED, SHALL BE CARRIED OUT EACH TIME THE TRAC-

TOR IS CONVERTED FROM ONE OPERATION TO ANOTHER AND IS REEQUIPPED WITH

OTHER IMPLEMENTS ANA INSTRUMENTS COUPLED!

6.4.2.9 Operation 17. Drain of sediment from fuel tanks

To drain the sediment from the fuel tanks it is necessary to perform the following:

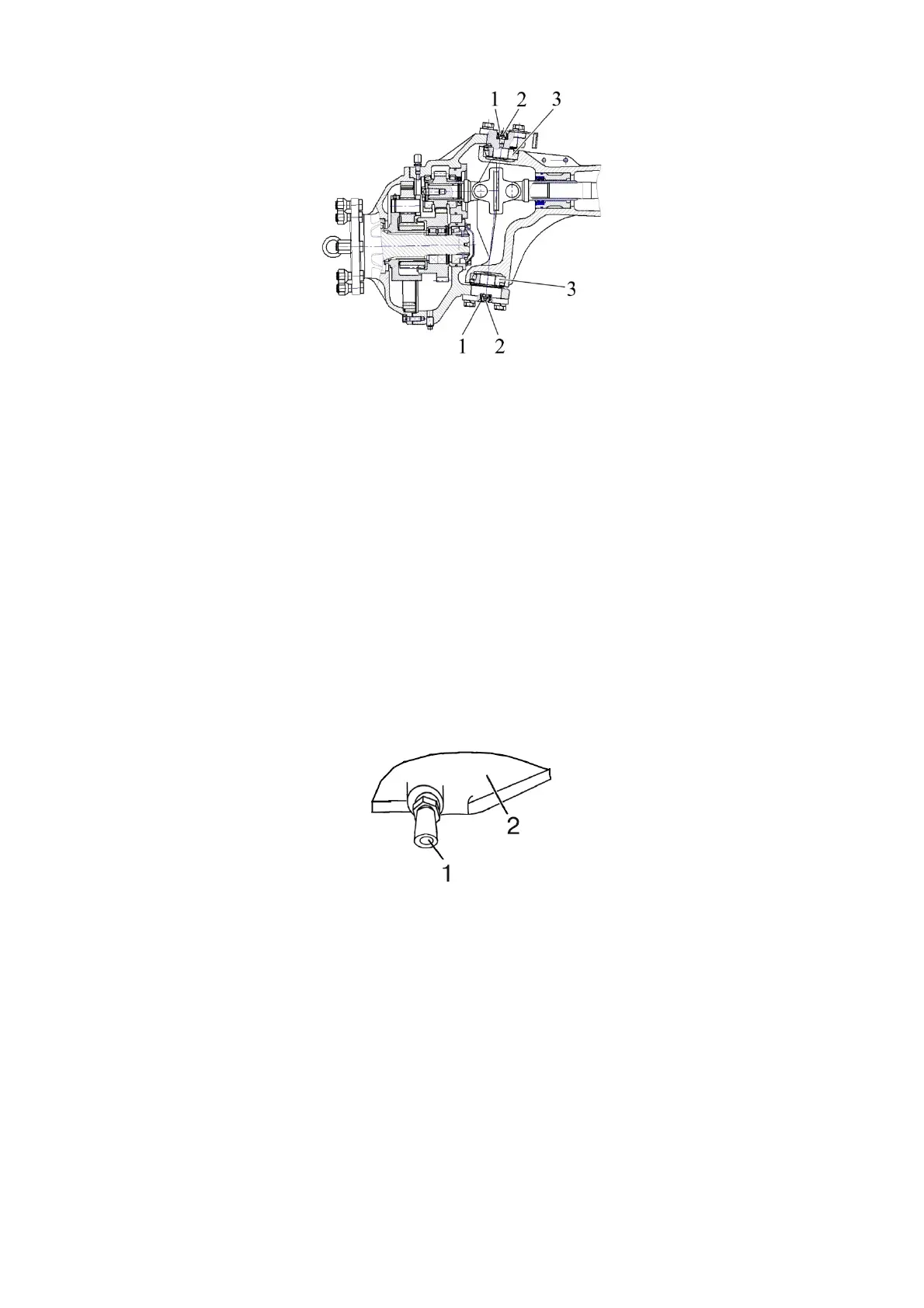

- screw out drain adapter 1 (Figure 6.4.10) located in the bottom part of the fuel tank2;

- drain the sediment until the clean fuel will appear;

- after the clear fuel without water and dirt appearance screw in the tank adapter 1,

1 – drain adapter; 2 – fuel tank.

Figure 6.4.10 – Drain the sediment from the fuel tank

ATTENTION: DRAIN THE SEDIMENT ONLY WHEN THE TANK IS FILLED WITH

FUEL MIN. TO 1/8 OF ITS VOLUME!

6.4.2.10 Operation 18. Drain of sediment from coarse fuel filter

To drain the sediment from coarse fuel filter it is necessary to perform the following:

- open drain plug 1 (Figure 6.4.11) of coarse fuel filter 2;

Loading...

Loading...