4 Routine Inspection

4.1 Cylinder Body

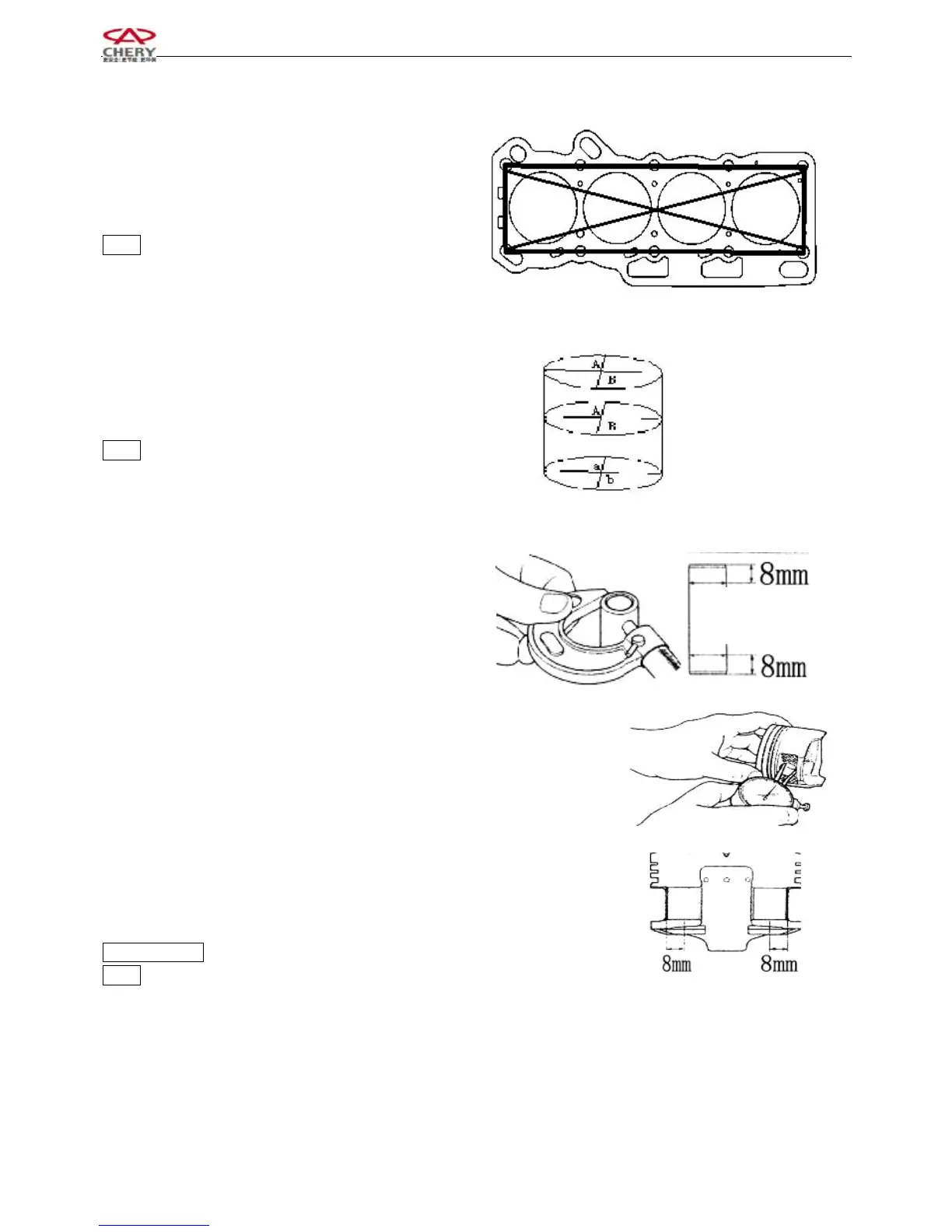

4.1.1 Inspect the top surface of cylinder body for its

flatness

(1) Measure at the six points shown in the right figure

with a ruler and a feeler gauge.

Limit: 0.08mm

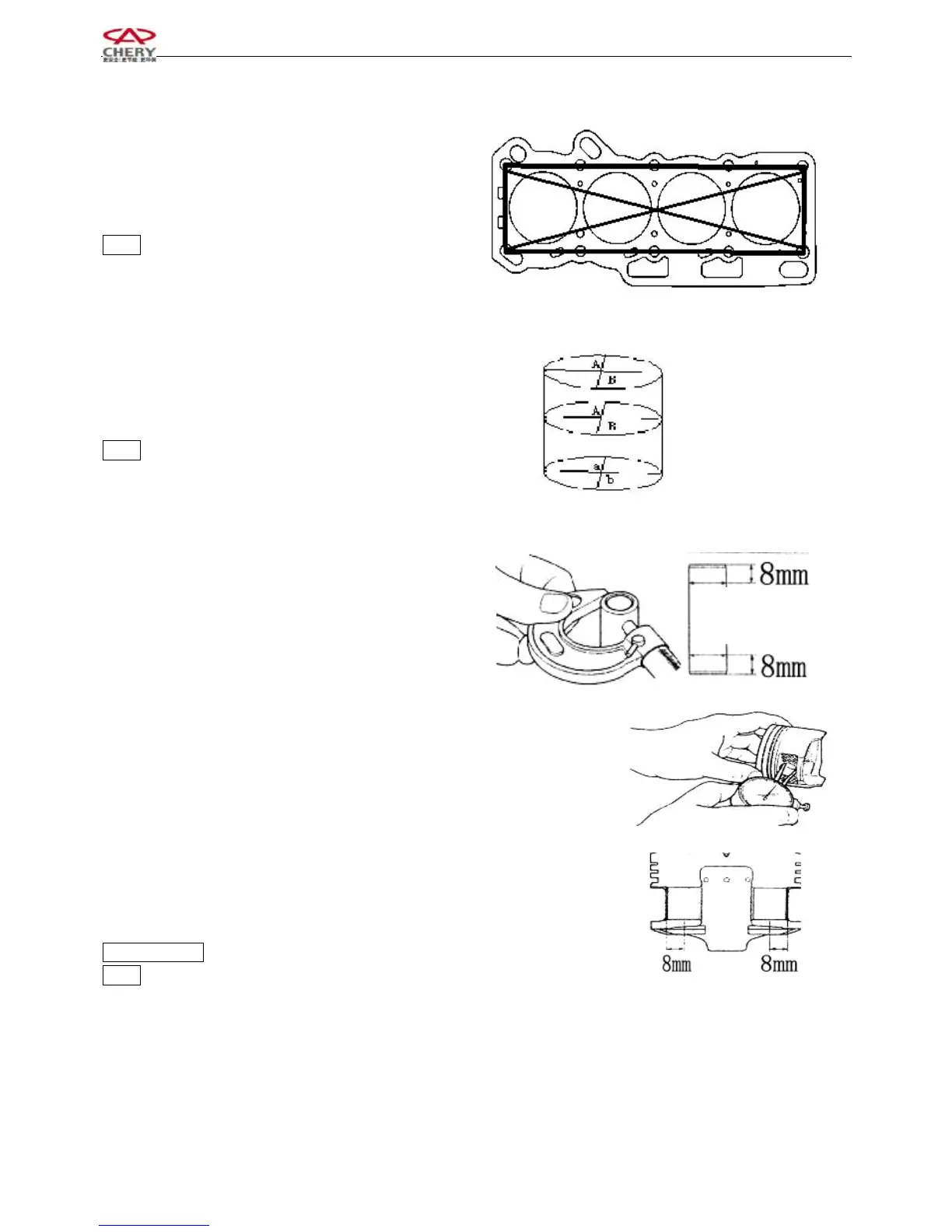

4.1.2 Use of bore gauge

Measure the cylinder bore at the positions as indicated in

the right figure with a bore gauge, and figure out the

difference between the maximum value and the miximum

value. If the difference exceeds the limit, repair or replace

the cylinder.

Limit: 0.03mm

[Reference] Roundness: A-B or a-b

Cylindric degree: A-a or

[Reference] Standard diameter of cylinder:

φ72.00-72.01mm

4.2 Piston

4.2.1 Inspect the piston pin hole for its clearance

Measure the piston pin at several positions with a

micrometer caliper shown in the figure, make the

maximum value as the diameter of pin.

4.2.2 Measure the diameter of piston pin at several

positions with an inner-diameter dial gauge as shown in the

figure, make the minimum value as the diameter of the pin

hole.

Work out the clearance with the diff

pin diameter and pin hole diameter, if the difference is

beyond the standard value, replace the piston pin or piston.

Loading...

Loading...