Chery QQ Service Manual Chassis System

8)Brake disc surface finishing

Points of attention: Don’t finish

disc to correct following process:

Brake noise.

Early wear of lining.

Surface corrosion.

Disc fade.

Only finish surface on one of following

conditions:

Serious scratch on surface of disc

with depth of 0.4mm.

The hop caused by following

reasons:

——The deviation of disc depth

exceeds 0.01mm.

——Corrosion or scratch depth

exceeds the surface of disc.

Attention: Whenever to remove the disc

from wheel flange, the corrosion or

dirt on disc or flange face must be

cleaned, otherwise it will cause

serious hop.

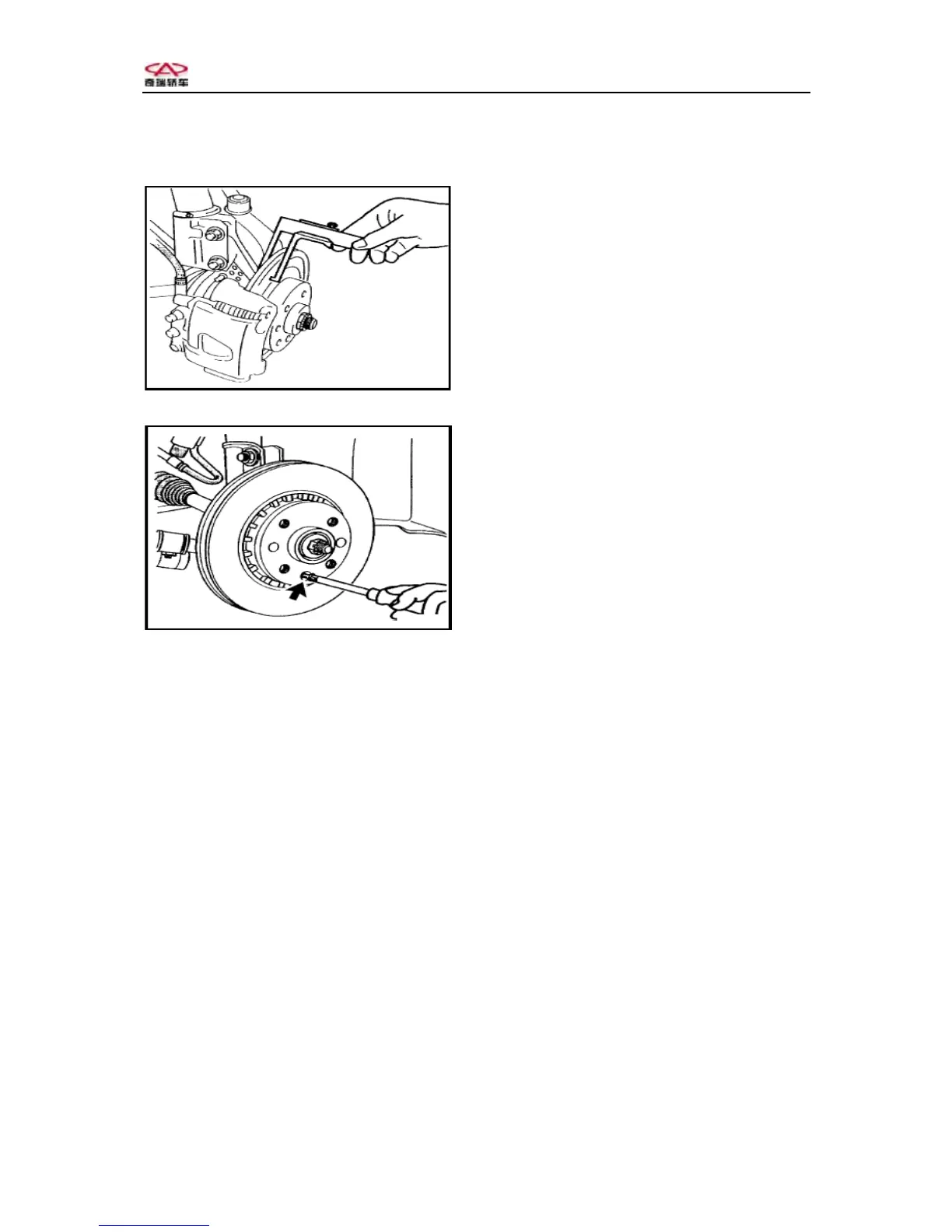

1、Clear the wheel bearing and hub.

2、Use micrometer to measure the

thinnest point on disc. If the

thickness of the point exceeds the

minimum thickness of disc, don’t

finish surface of disc. Replace disc at

once.

3、Clear completely the corrosion on

flange.

4、Finish the disc.

Points of attention: If the best

surface finishing could not be reached,

it will cause bad brake ability.

5、After machining the disc, use alumna

to get unidirectional surface.

6、Clean surface with suitable cleaning

fluid

Attention: Loose wheel bolts will

cause brake hop or damage. Screw wheel

nuts to specified torque to avoid

expensive service for brake system.

4. Description and operation

Disc braking system

Points of attention:

Use clean fluid to lubricate all

rubber parts for better

installation.

Don’t use compressed air with

lubricant.

Whenever to remove hydraulic parts,

drain out all air in system.

Replace whole lining assembly.

Fix dry parts in specified torque.

Operate on clean working desk.

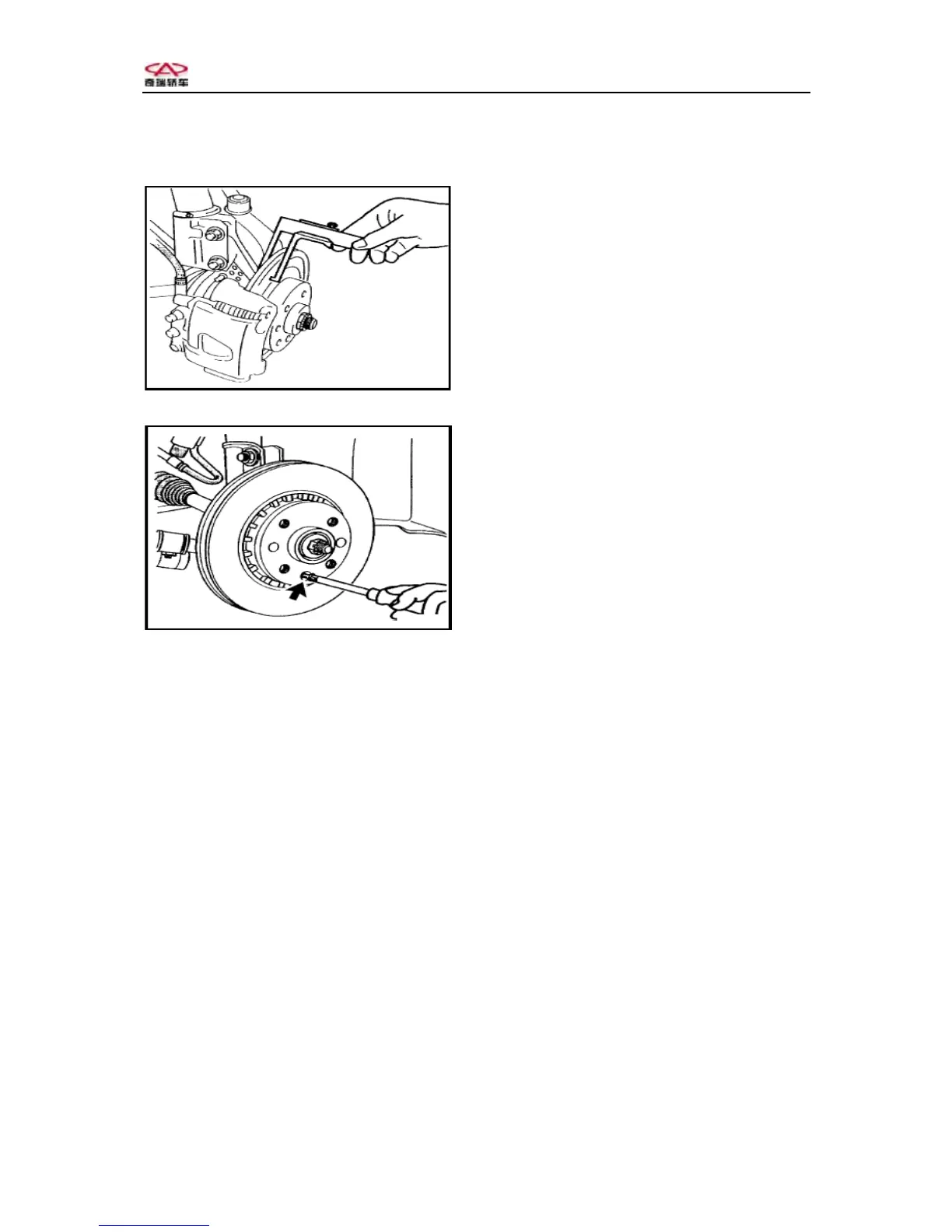

The caliper has a single cylinder.

The caliper is mounted on the

32

Chery Automobile Co., Ltd

Loading...

Loading...