Chery QQ Service Manual Body System

2)Not knocking the beam pad with hammer. This method means put the beam pad under the

lowest place of the hollowness, knock the nearby place with hammer.

Generally speaking, while trimming the hollowness with hammer and beam pad ,the protruding

side shall be knocked by the hammer, the other side shall be gasket ,you can make rough shaping

with wooden hammer then make fine trimming with iron hammer.(see figure 7).In the case of

hollowness with much bigger area, beam pad shall be put in the more shallow position of the

hollowness, the hammer shall knock the much higher position of the protruding, iron hammer

and wooden hammer shall be used alternately accordingly.

(2)Trim the hollowness with jimmy. jimmy can be self-made according to characteristic of the

vehicle body, they are handwork tool in common use for door maintenance. can be used to put

into the limited space of sandwich position of doors and lids ,it can prize open the hollowness,

this kind of method can be applicable to the hollowness which is not easy for spacer and hammer

to reach because of the narrow sandwich position of doors and lids, can be also used as the

spacer to make the hitting power of the hammer spread in much larger area.

(3)Trim the hollowness with puller. puller can be used to trim the shallow hollowness which is

difficult for other tools to touch upon, it is can be used inside the metal plank. There are two

operating methods of puller in common use.

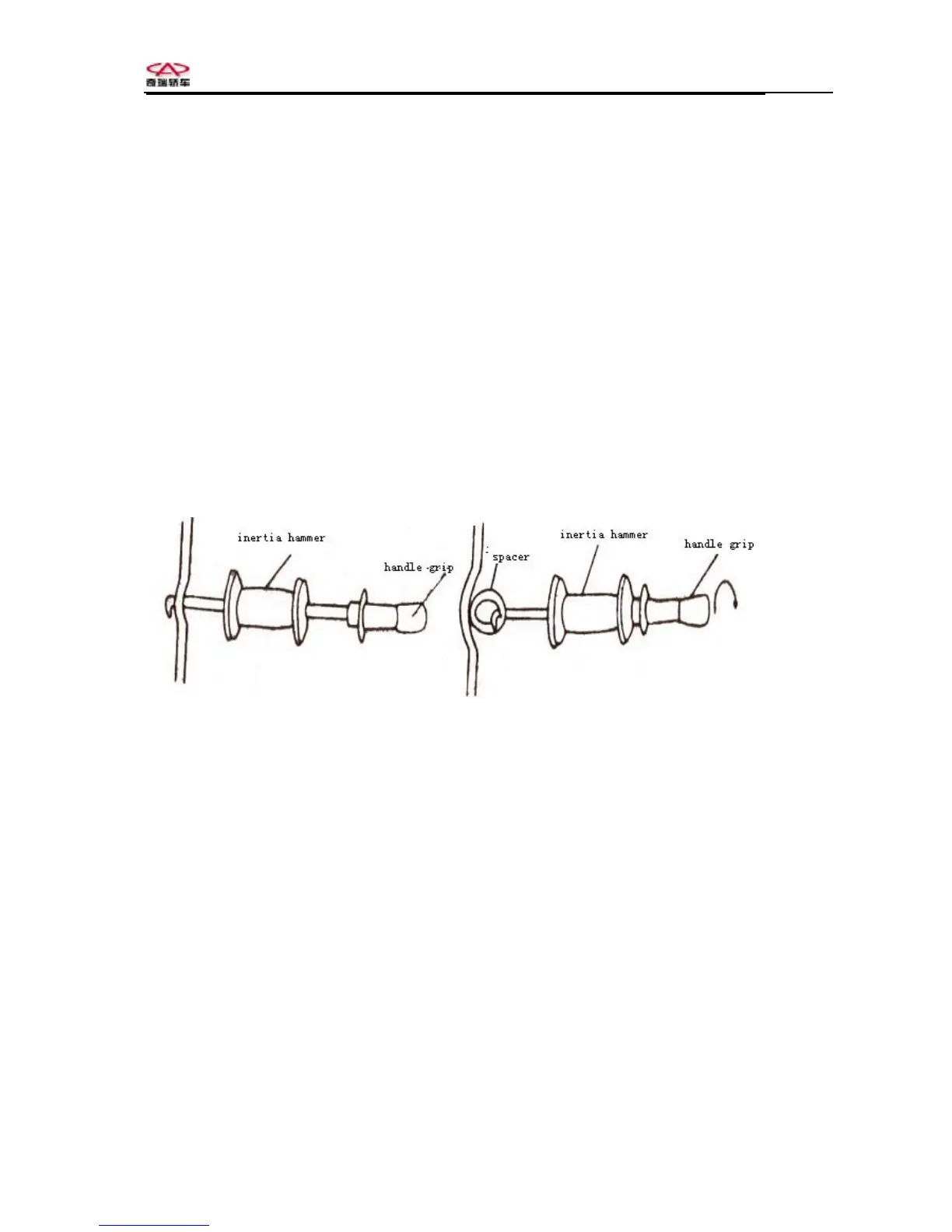

One is boring method. That means to drill a small hole in the hollowness with portable electric

drill, then insert the withdrawal lever of thread summit or hook summit in the hole, draw the

hollowness slowly through inertia hammer sliding on the metal withdrawal lever and colliding

the handle repeatedly. You can drill more holes when necessary, fill and smooth the holes with

tin-lead bonding after the hollowness is flattened.

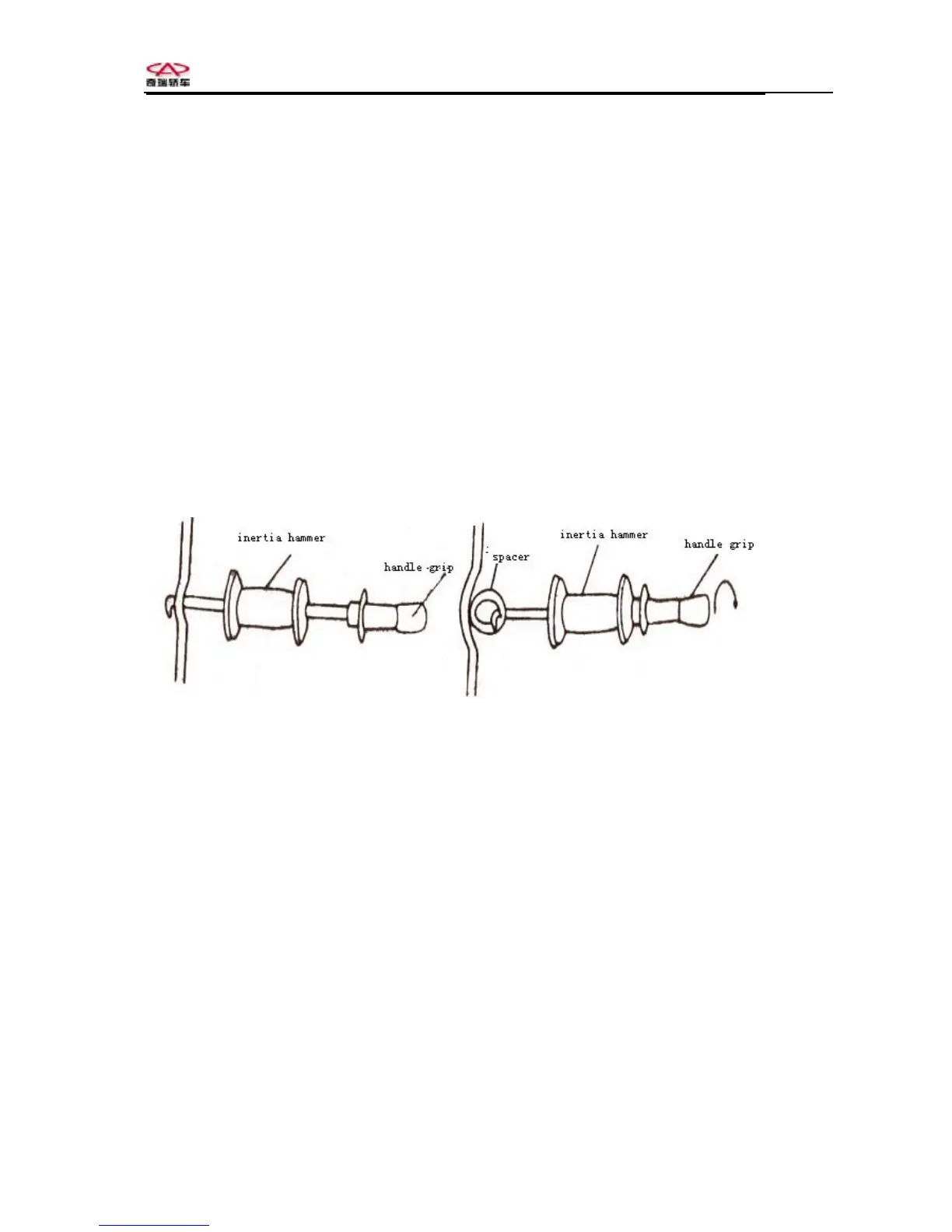

The other method is electrode welding.That means welding the stud nail or spacer on the

hollowness with special use spot welder, then pull the stud nail or spacer outwards

withpuller,until the hollowness is flattened. You can weld more nails and spacer accordingly, pull

the whole hollowness gradually. Finally, polish the welded mark and smooth it with grinder. This

kind of method avoids making holes in the metal plank; eliminate the potential corrosion of

metal.

2.2.2 Recovery of stretchable position

It happens frequently that sheet metal of the hollowness is stretched after being collided. It is not

sure that the stretchable position can be recovered completely using the correct operational

method during trimming process ,therefore, it is necessary for you to combine with heating

contraction method to achieve the goal of trimming.

- 13-

Chery Automobile Co., Ltd

Loading...

Loading...