D 30 21

A

The scraper scrapes the separator fluid off the belt again, causing it to be wetted and

protected against material adhesions.

A

Repeat spraying regularly in the continuous working gear; see the following table

for orientation:

A

Spray all other parts which come into contact with asphalt using the manual spray.

Engagement is carried out on the operating panel / side operating unit.

m

Only switch on the spraying system when the diesel engine is running; otherwise,

the battery will be discharged.

Switch off after use.

f

Refill the tank only whilst the vehicle is stationary!

f

Do not spray into open flame or on hot surface! Danger of explosion!

m

Use only approved separator fluid!

See section entitled "Lubricants and operating substances".

- Hose reeling device: connect supply hose with quick-action coupling.

- Pull the spray hose out of the device until a click is audible. When released, the

hose automatically engages here. The hose is automatically rolled up again by pull-

ing and letting go again.

- Actuate the manual valve (7) to spray.

- If the system is not in use, place the spray lance in the holder (8) provided.

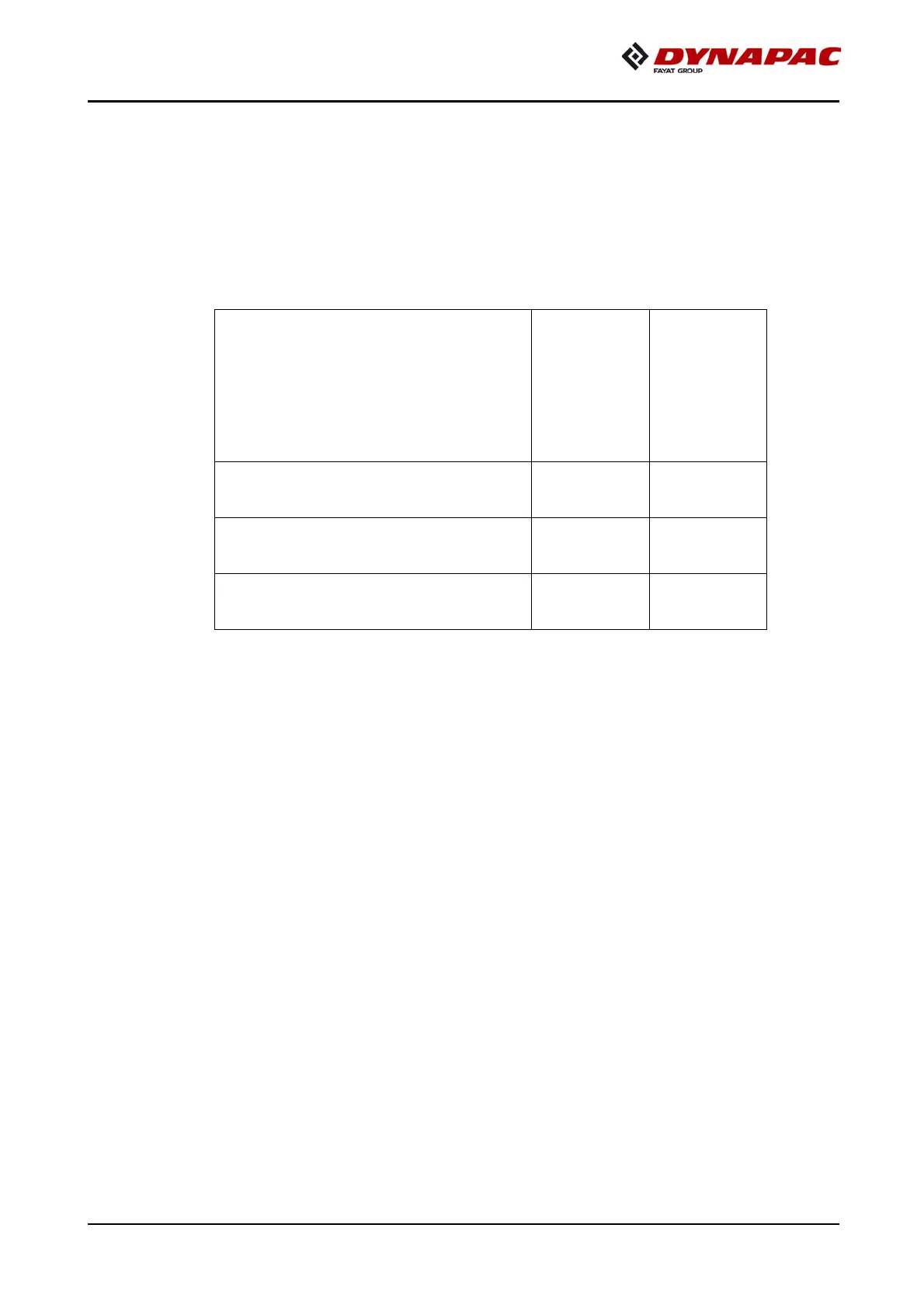

Base course

Binder course/

surface course

- Truck loads between two spray-

ing processes

4 2

- Separator fluid consumption

of feeder

approx. 10 l approx. 20 l

- Separator fluid consumption

of feeder with slewing belt

approx. 20 l approx. 40 l

Loading...

Loading...