F 30 26

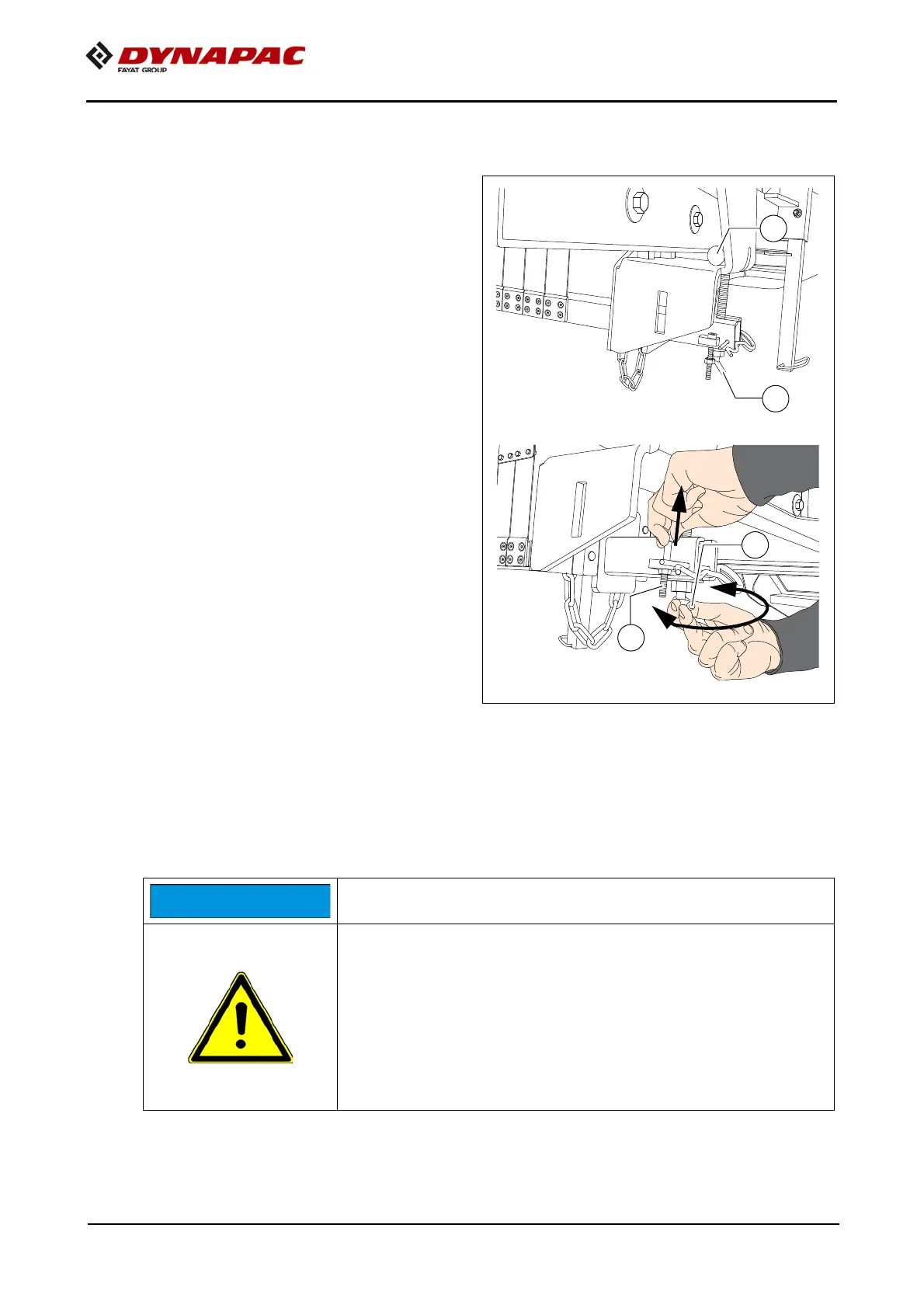

Scraper basic setting

A basic setting must be carried out after

changing or adjusting the blades.

- Screw the adjusting screws (E)

on both sides of the scraper into the

pins (L) until the thread ends flush with

the surface of the pin.

A

Locking pin (G) must be raised for ad-

justment.

- Evenly tighten the adjusting screws

(E) in steps on both sides of the scrap-

er until all scraper blades have perma-

nent contact with the conveyor belt.

- Exit danger area and carry out

test run:

Visually check whether all scraper

blades are in permanent contact with

belt while conveyor belt is running.

Carry out a complete belt circulation

when doing so.

- If necessary, switch off conveyor belt

and retension adjusting screws (E) on

both sides in steps of 0.5 rotations.

- Repeat process until correct setting is achieved.

m

Should the conveyor belt chain tension be changed, then the adjustment of the scrap-

er must also be checked and, if necessary, adjusted.

Caution! Possible collision of parts

The following adjustment must be made before starting up

the slewing belt:

- Move the scraper of the main conveyor belt located over

the slewing belt into the working position.

- Carry out a collision check by slowly slewing the

slewing belt.

- If necessary, adjust the height adjustment of the main

belt to prevent a collision.

Loading...

Loading...