F 32 7

Belt tension

m

Check belt tension on a daily basis. If

there is too much slack in the belt, adjust

the tension.

Increasing the tension:

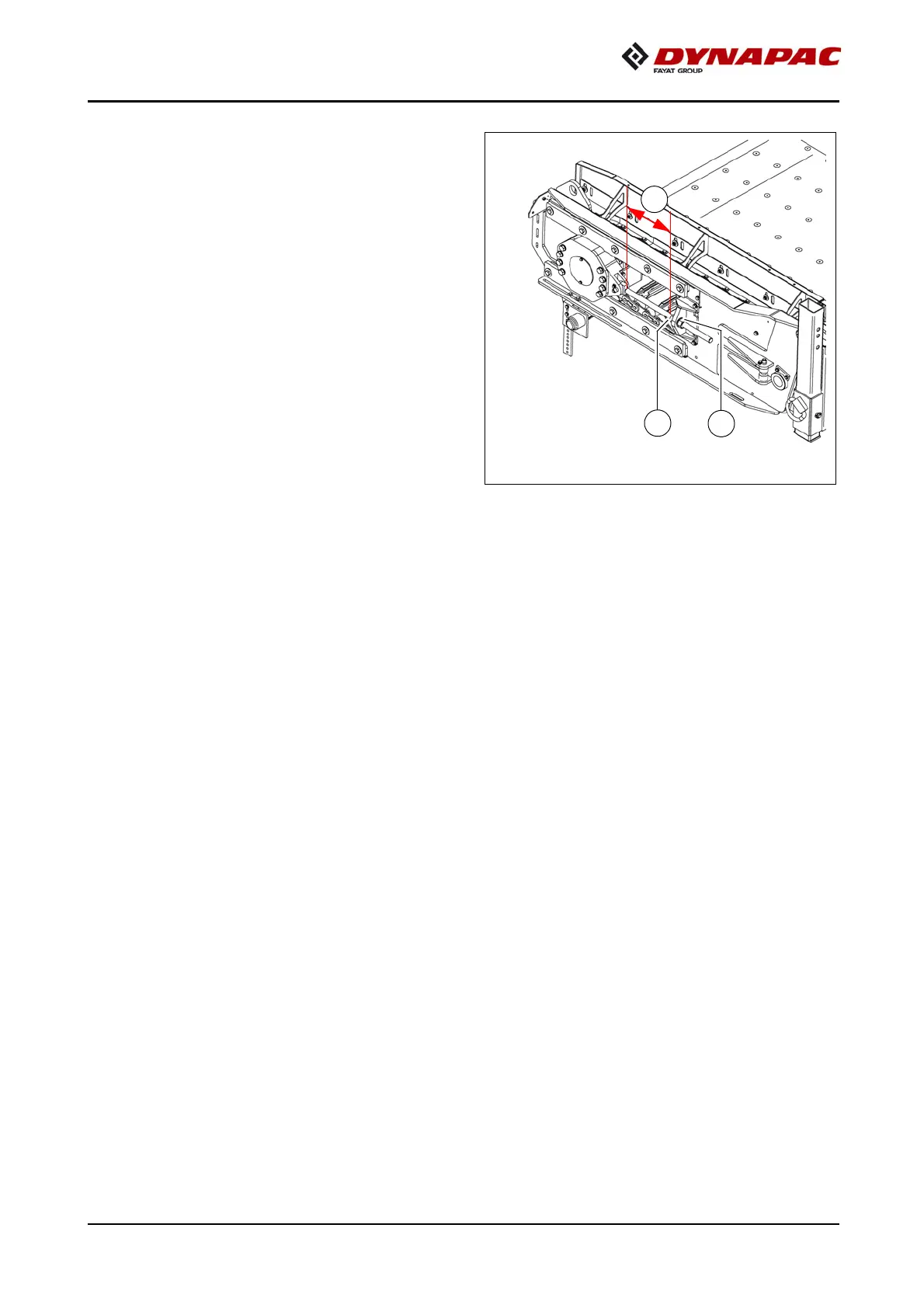

- Unfasten lock nuts (A) on both sides of

the tensioning fixtures.

- Use an open-end wrench to adjust

tension on both sides evenly on the

adjusting nuts (B).

- Tighten lock nuts (A) back down after

the adjustment procedure.

A

If the belt on the reversing drum is run-

ning to one side, tighten the right-hand spindle or loosen the left-hand spindle if the

drum is rotating clockwise, or vice versa for anti-clockwise rotation.

m

Avoid an inclined position of the reversing drum because this can cause damage to

the conveyor belt.

m

After completing the adjustments, check whether the belt tension has been restored

evenly on both sides. The length of the spindle (C) must be identical on both sides!

A

At the latest, the drive chains and conveyor belt must be exchanged when their elon-

gation has progressed so far that they can no longer be re-tensioned.

m

Chain links must not be removed to shorten the chain!

Incorrectly dividing the chains would lead to destruction of the drive wheels!

Loading...

Loading...