F 32 17

A

Locking pin (C) must be raised for adjustment.

- Check the adjustment constantly: Switch the conveyor on and observe the scraper

from a safe distance.

Ensure:

- that all scraper blades move forwards and backwards evenly

- that all scraper blades have contact with the conveyor belt at the same time

- If necessary, switch the conveyor off and retighten the scraper evenly in steps of

1 to 2 turns (T-bolts (A))!

- Repeat process until correct setting is achieved.

A

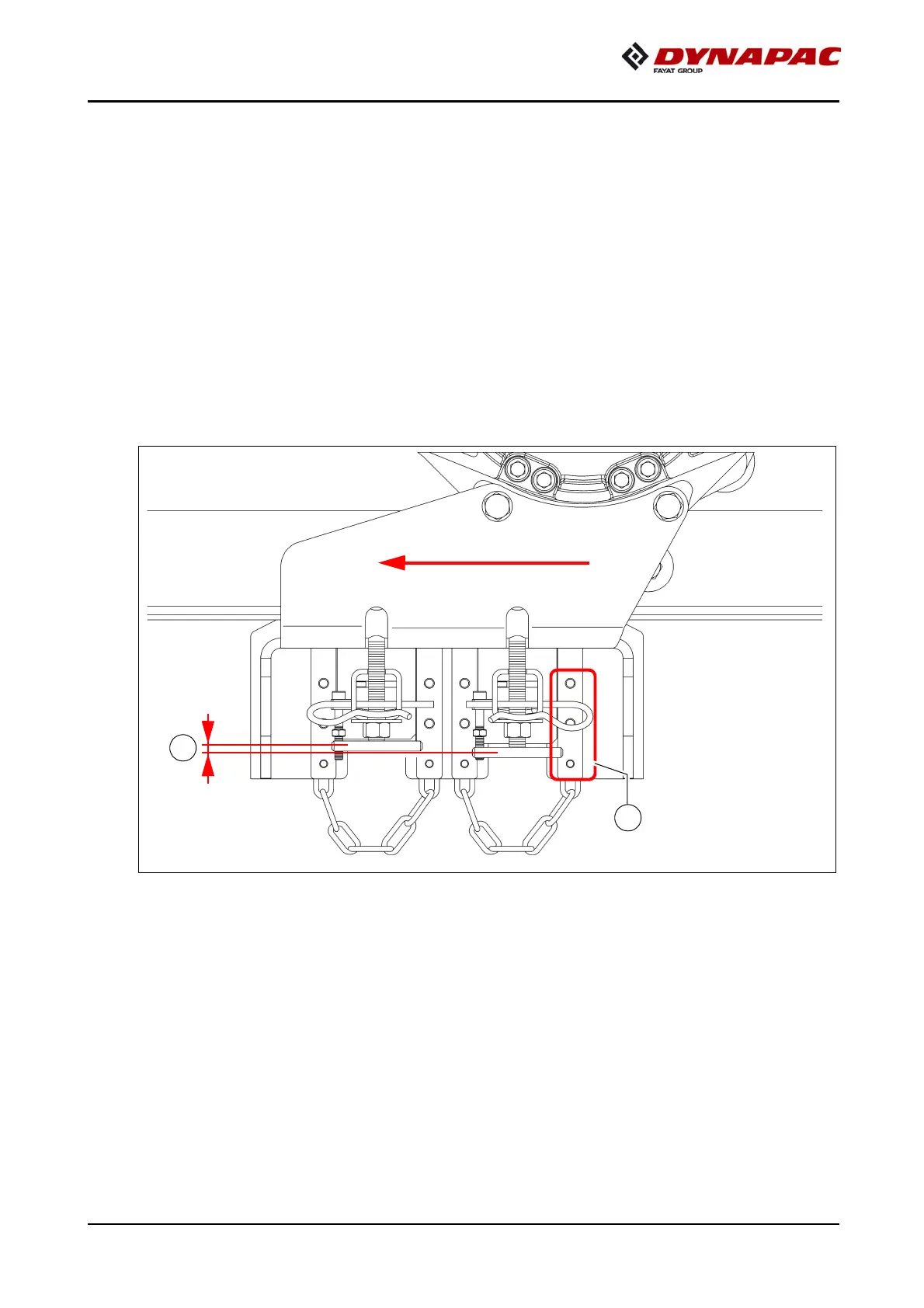

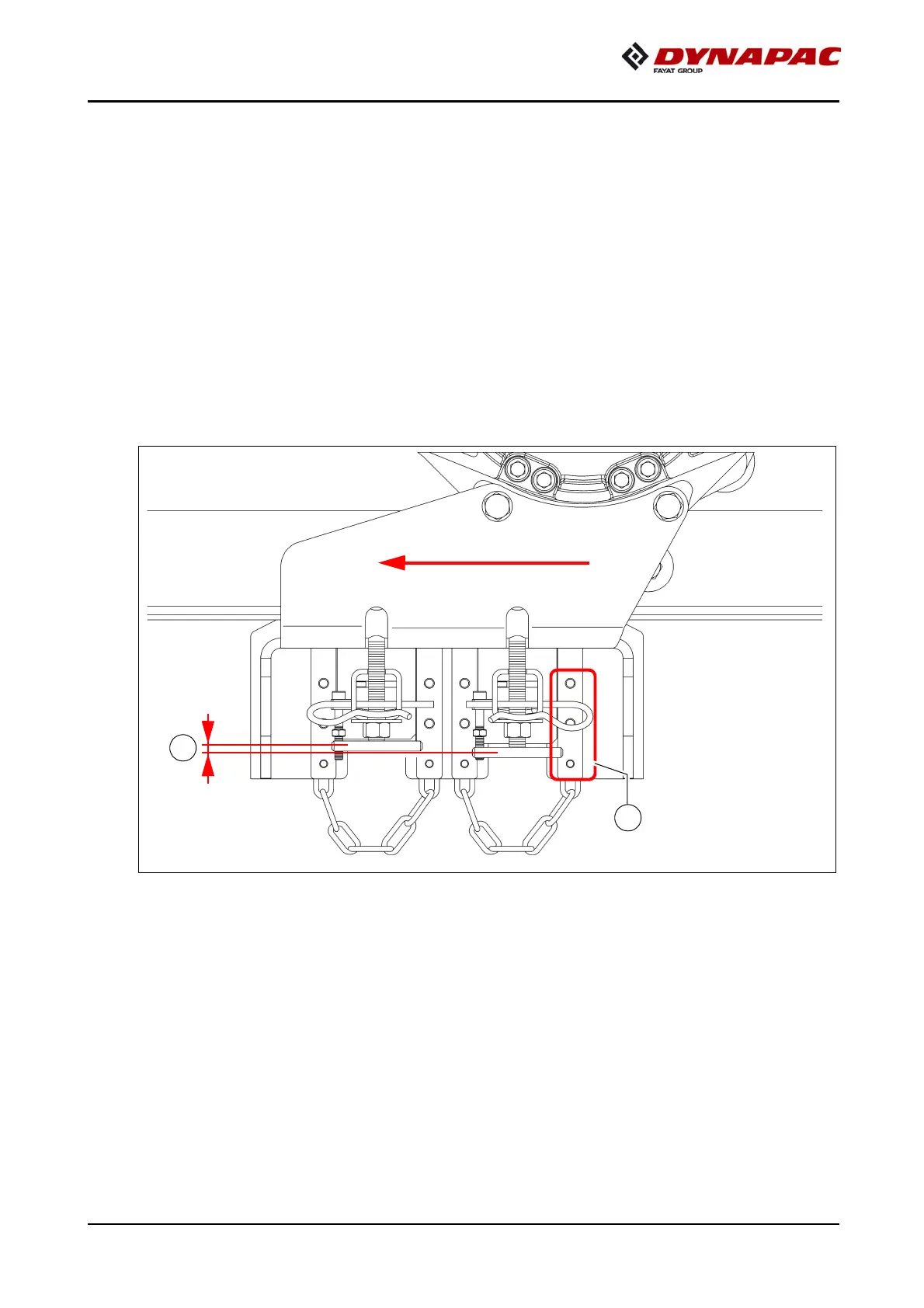

The following drawing shows a typical adjustment.

The distance between the lower edge of the guide plate and the visible ends of the

bolt (D) acts as guidance.

A

The depicted adjustment serves as an indicative value: the position of the scrapers

can vary by a few millimetres, depending on

- conveyor belt tension (pay attention to correct adjustment!)

- scraper wear

- production tolerance

A

The front scraper in the travel direction is at a greater distance from the deflection axle

and is therefore always higher (E) than the rear scraper.

Loading...

Loading...