F 90 4

Central lubrication system

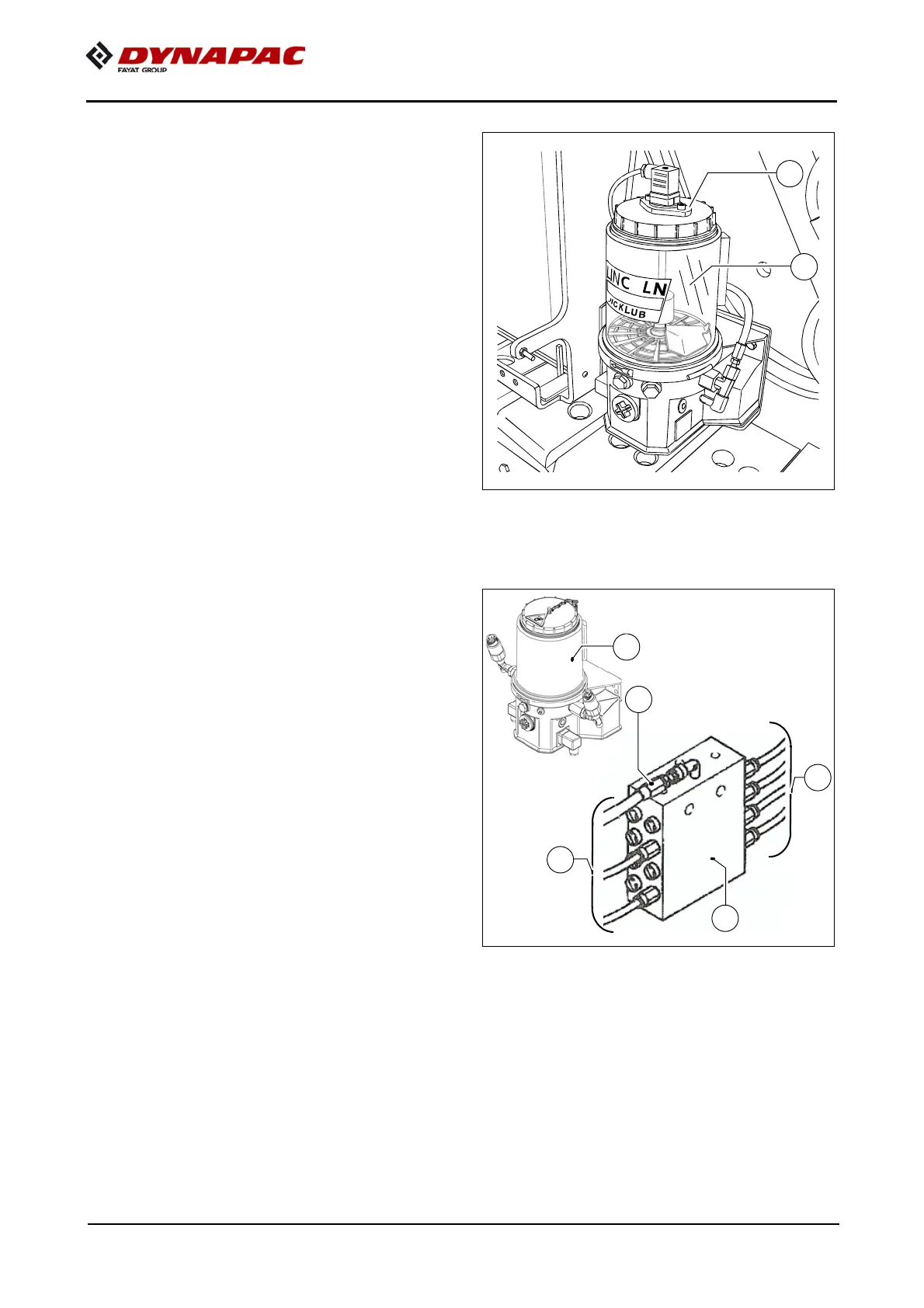

Check filling level

A

The lubricant tank should always be filled

sufficiently so that the system cannot "run

dry", ensuring sufficient drive chain lubri-

cation and eliminating the need for time-

consuming bleeding of the system.

- Always maintain a fill level above the

"MIN" mark (a) on the tank.

Top up lubricant tank

- Unscrew cap (b) and fill tank from

above.

A

When the lubricant tank is completely empty, the pump may have to run for up to 10

minutes until the full delivery rate is achieved after filling.

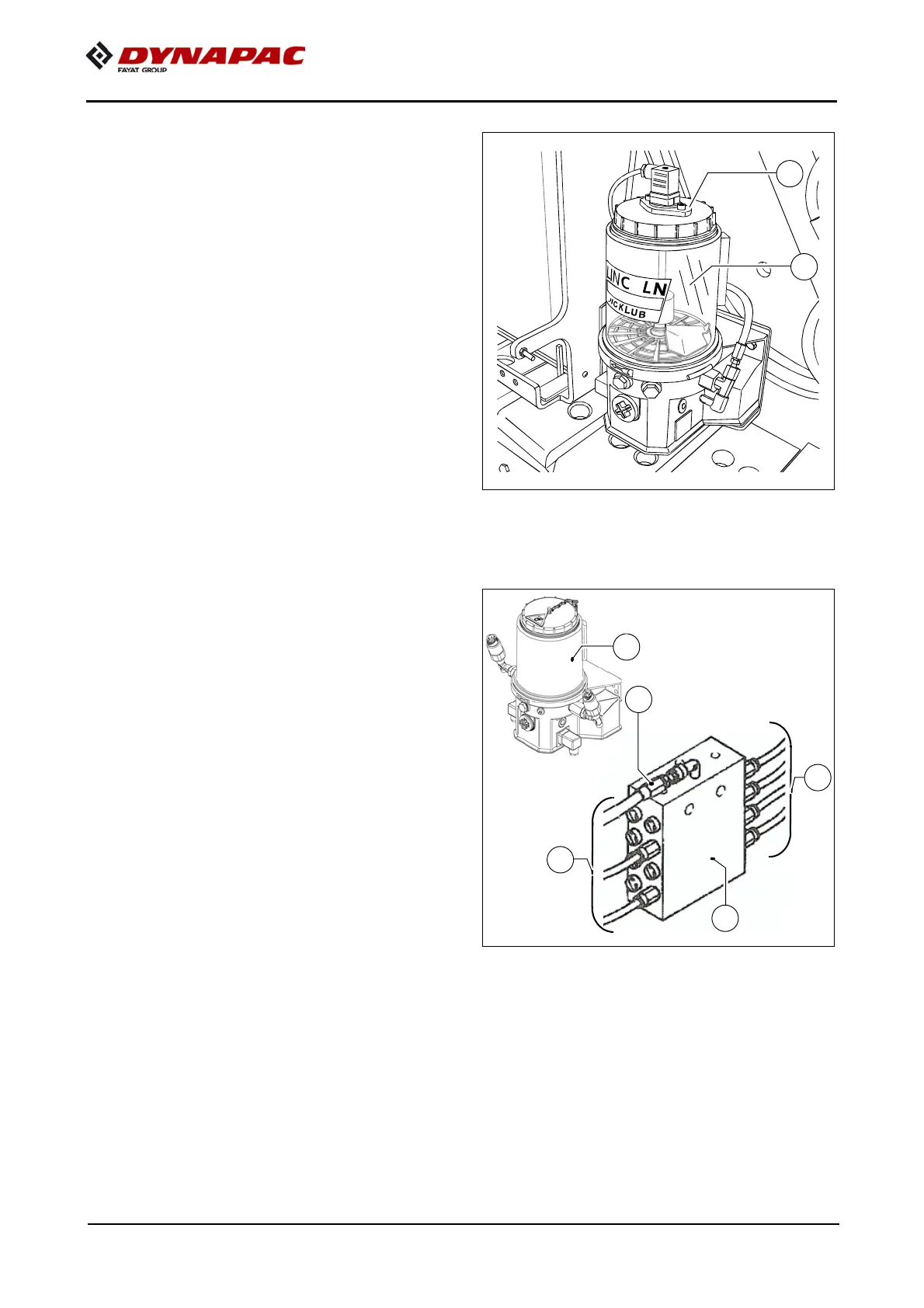

Bleed central lubrication system

Bleeding the lubrication system is nec-

essary if the central lubrication system

has been operated with an empty lubri-

cant tank.

- Release the main lubrication line (a)

at the distributor (b).

- Start up the central lubrication sys-

tem with the filled lubricant tank (c).

- Allow the pump to run until lubricant

emerges from the previously re-

leased main line (a).

- Reconnect the main line (a) to the

distributor.

- Release all distribution lines (d) from

the distributor.

- Reconnect all distribution lines as soon as lubricant has emerged.

- Check all connections and lines for leaks.

Loading...

Loading...