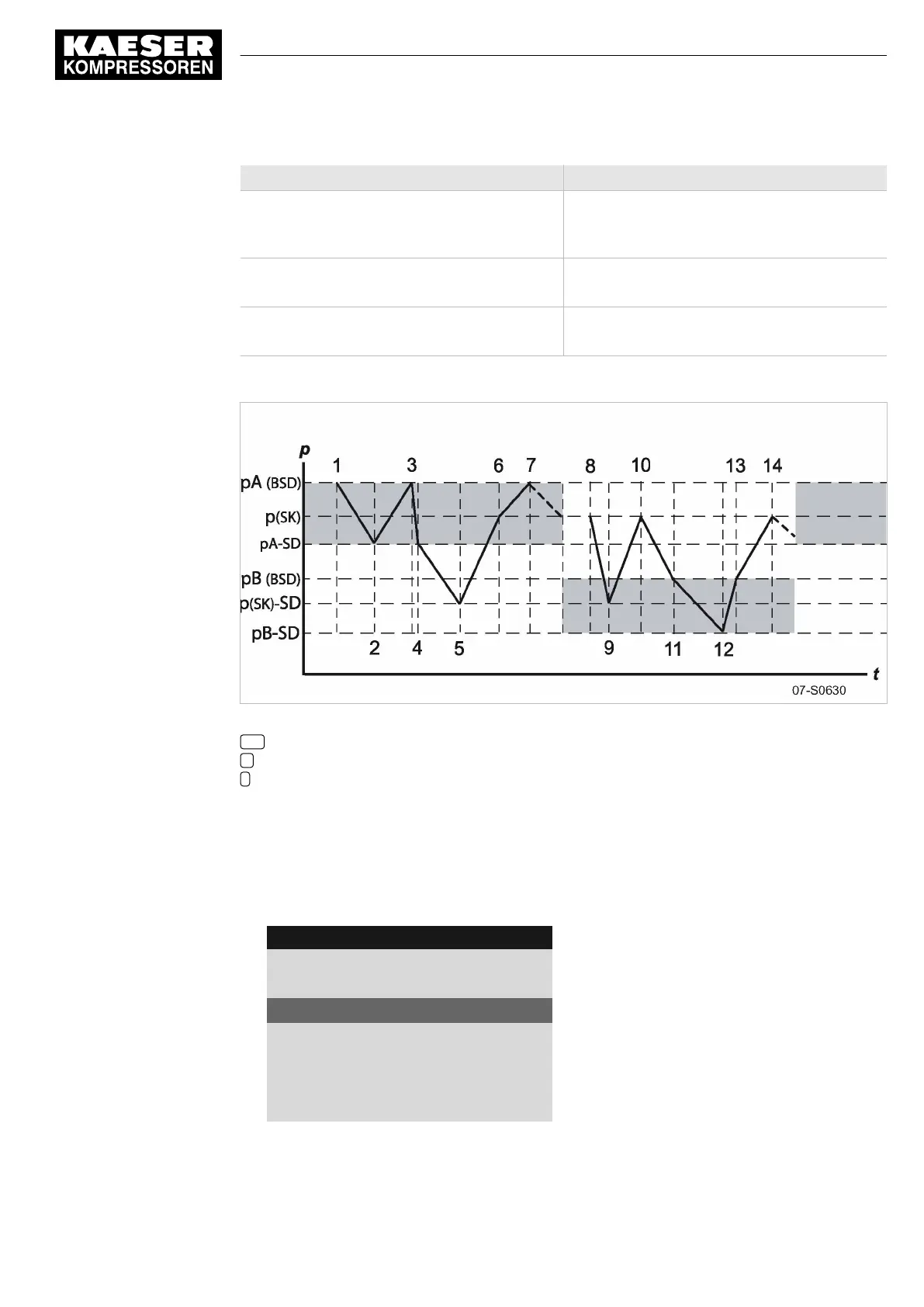

Period t1–t7: high air demand Period t8–t14: low air demand

t5:

SK also switches to LOAD.

System pressure pNloc begins to rise.

t12:

SK switches to LOAD.

System pressure pNloc begins to rise.

t6:

SK switches to IDLE.

t13:

SK switches to IDLE.

t7:

BSD switches to IDLE.

t14:

BSD switches to IDLE.

Tab. 71 Function diagram

Fig. 39 Function diagram

SD Switching differential

p Pressure

t Time

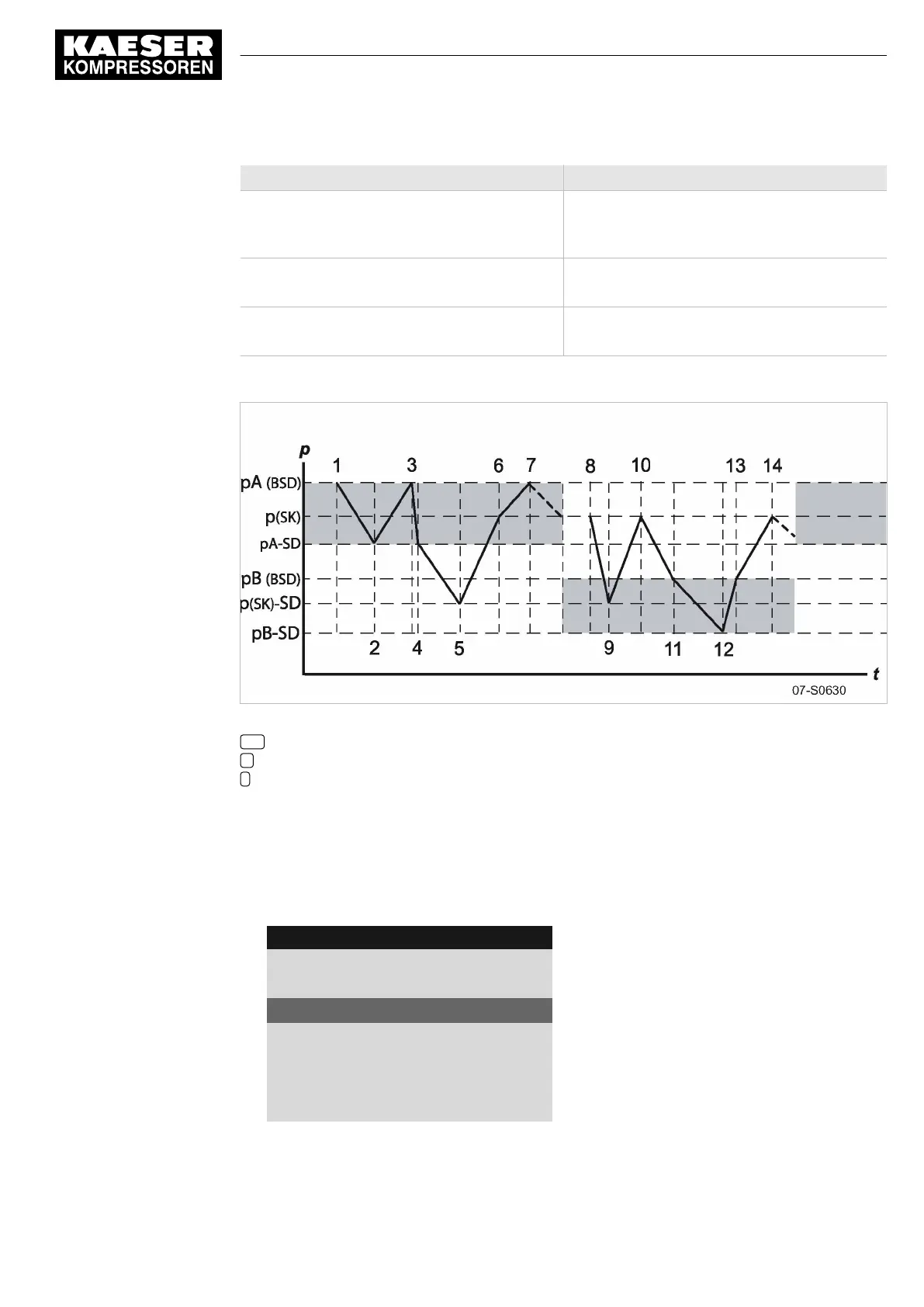

Set the system setpoint pressure pA and pB.

Precondition Password access level 2 is activated.

1. Open the

<5.2.2 – Pressure control – Pressure settings>

menu (see chapter 8.4.1).

2. Use «Up» or «Down» to select the

pASP

line.

8 8 p s i 0 8 : 1 5 A M 1 7 6 ° F

Header

5.2.2 Pressure settings

Menu

Setpoint pressure

pA SP: 123psi ¦ SD: −7.3psi

Active line

pB SP: 119psi ¦ SD: −7.3psi

·········

System pressure low ☐

↓ < 72.5psi ¦ SD: 7.2psi

3. Press «Enter».

The

pA

display flashes.

8 Initial Start-up

8.10 Configuring the machine for master control

No.: 9_9450 13 USE

User Manual Controller

SIGMA CONTROL 2 SCREW FLUID ≥5.1.2

149

Loading...

Loading...