8.10.2.1 Reaction in the event of a communication malfunction

After switching on the power supply, monitoring for communication malfunctions is suppressed for

a period of time which can be defined by means of the

Start td

parameter. The setting depends on

the time passing at the bus master between return of power and start of communication via the

bus.

For the communication with SAM 4.0, the value of Start td must be set to 30 s.

SIGMA CONTROL 2 can monitor the bus communication at user level. For this purpose, the bus

master reads a value ("toggle bit") that changes with every bus cycle and returns it without change.

SIGMA CONTROL 2 returns a communication malfunction if the value does not change for a time

longer than set (

Timeout

).

Monitoring for communication malfunction can be activated if needed. For this purpose, the

Send/receive

option must be set for the data exchange. Activate the

Communication error

check box to enable monitoring for communication malfunctions.

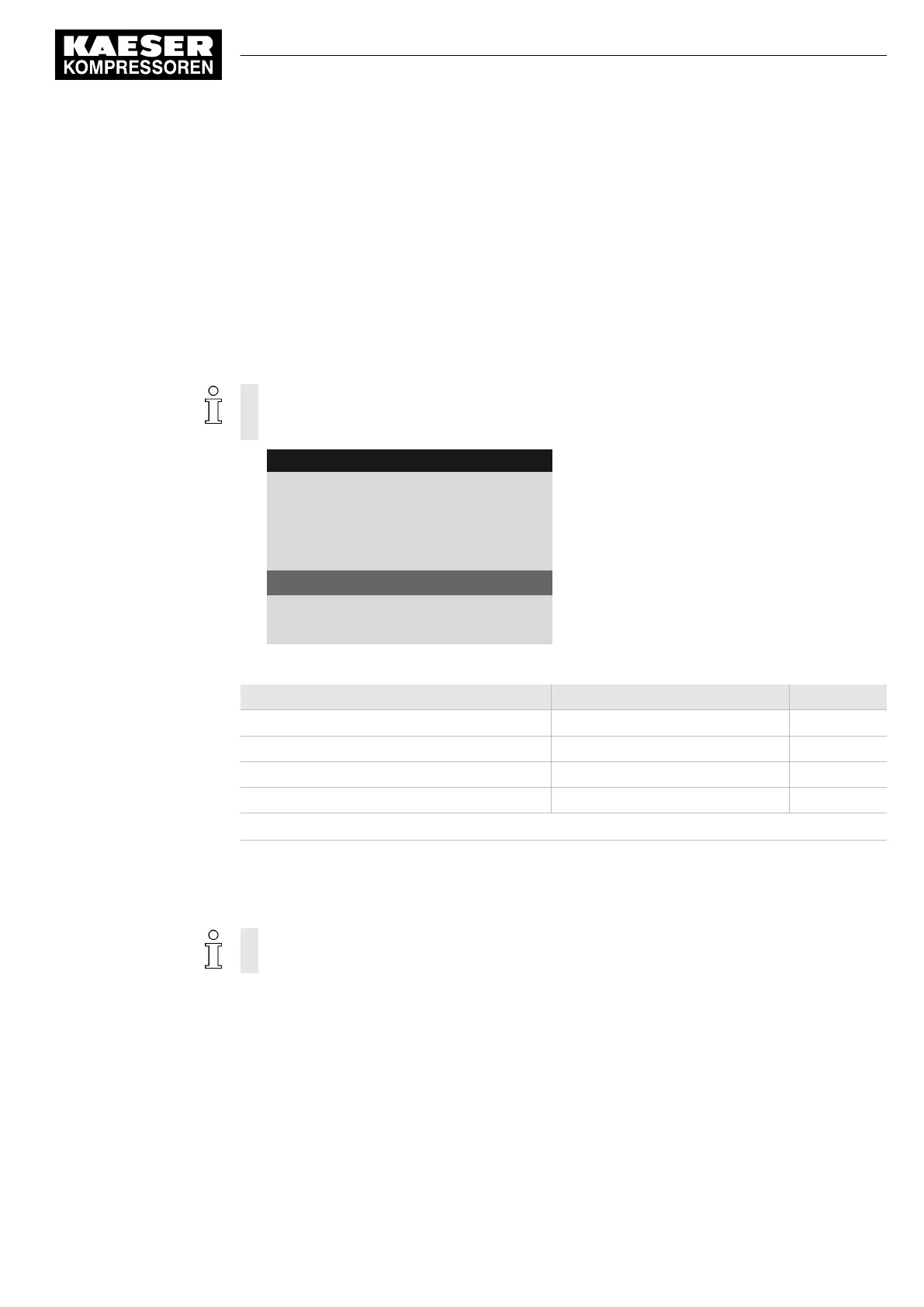

8 8 p s i 0 8 : 1 5 A M 1 7 6 ° F

Header

8.1.2.2 SAM 4.0

Menu

IP address : 169.254.100.100

Port : 2000

·········

Communication error : ☑

Active line

Start td 30s

Timeout : 5s ☑

Settings for connection to SAM 4.0.

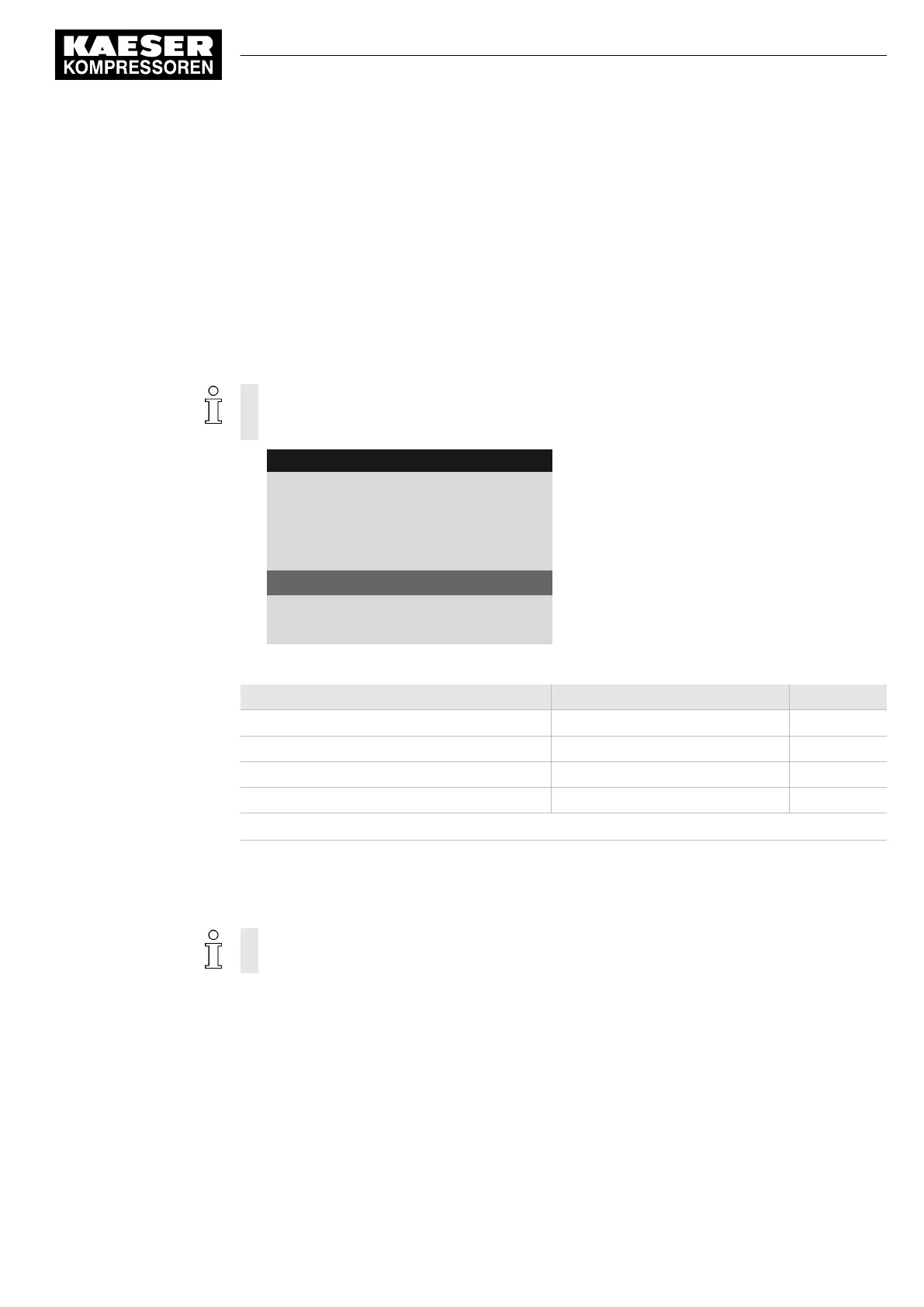

Parameters Factory setting Set value

Check box Communication error

Check box ☑ activated

1)

Start td 30 s

Timeout 5 s

Check box Timeout Check box ☑ activated

1)

Prerequisite: The

Send/receive

option has been set.

Tab. 68 Parameters for monitoring for communication malfunction

8.10.3 Configuring PROFIBUS mode (SIGMA AIR MANAGER)

Only possible with SIGMA CONTROL 2 (prepared for connection to control center)

Overview:

■ PROFIBUS DP-V0 Retrofit Kit required

■ Establishing the electrical connection

■ Setting the remote operating mode

pB

.

■ Setting the PROFIBUS interface

■ Activating the «Remote control» key

Precondition Retrofit kit PROFIBUS required

8 Initial Start-up

8.10 Configuring the machine for master control

No.: 9_9450 13 USE

User Manual Controller

SIGMA CONTROL 2 SCREW FLUID ≥5.1.2

123

Loading...

Loading...