Operation

Diesel engine

149 / 476

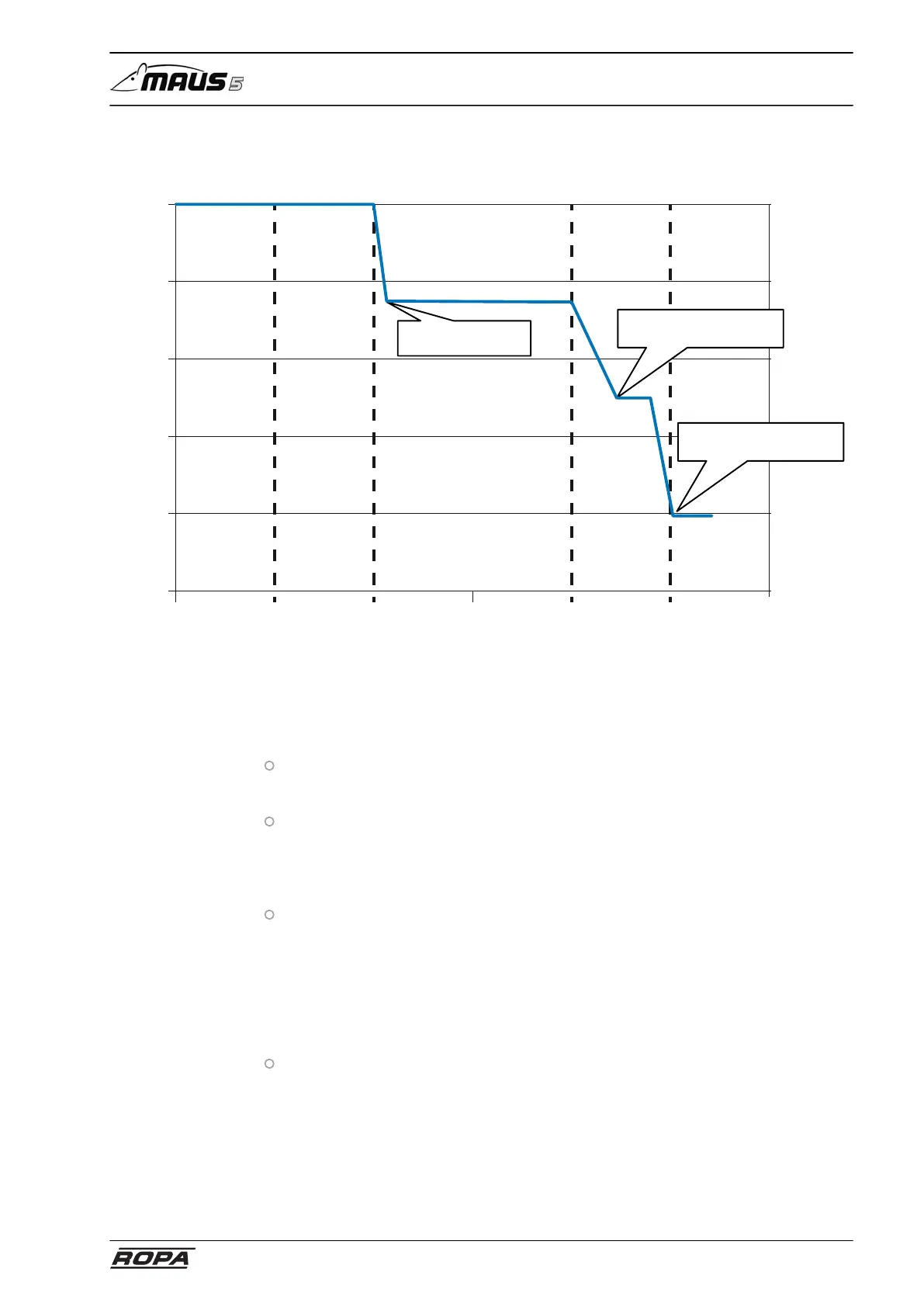

6.6.4.3 Power reduction process

Error detection Warning Slight reduction

(in 15 min.)

Time in minutes

Engine torque

Strong

Reduction

Full

Reduction

80%

60%

40%

20%

0%

100%

0 60 120 180 240

100% - 75% torque

100% - 60% nominal rotational speed (25 min.)

75% - 50% torque (1% / 25 min.)

60% -idling speed (10 min.)

50% - 20% torque (10 min.)

6.6.5 Modifications respectively additions to the engine operating

manual from Mercedes-Benz

The followings items listed below must generally be considered for the engines from

Mercedes-Benz, which are installed in ROPA machines:

The engine OM 936 LA 260kW and 1400 Nm is installed. This means that only a

part of the operating manual from Mercedes-Benz applies, namely those referring

to these engine models, and those parts generally applying to all engine models.

All engines are not fitted with a flame starter system, but with a constant throttle

brake. Control is performed using the CPC4 control device via CAN bus. This con-

trol device is located in the central electrical system. The exhaust after-treatment

system of the machine is controlled by ACM. This is located somewhat in the mid-

dle/left side of the machine frame over the rear side of transmission.

The "Warning lamp electronics" and the "Stop lamps" mentioned in the operat-

ing manual from MTU/Mercedes-Benz are replaced by warning indications on the

R-Touch for the ROPA machines. But the meaning for these indications is iden-

tical to the lamps described in the operating manual from MTU/Mercedes-Benz.

As soon as the STOP indication is displayed on the R-Touch, the engine must be

IMMEDIATELY shut off, because there is a severe engine fault, which may lead to

an engine breakdown in case of further operation. The control lamp "Charging cur-

rent" is also replaced by a warning indication on the R-Touch for ROPA machines.

The diagnosis socket (X-340 (1)) for the engine electronics is located in the front/

top of the central electrical system.

Loading...

Loading...