Lists/Tables/Plans/Diagrams/Maintenance Verification

Lubricating plan (lubrication with grease gun)

442 / 476

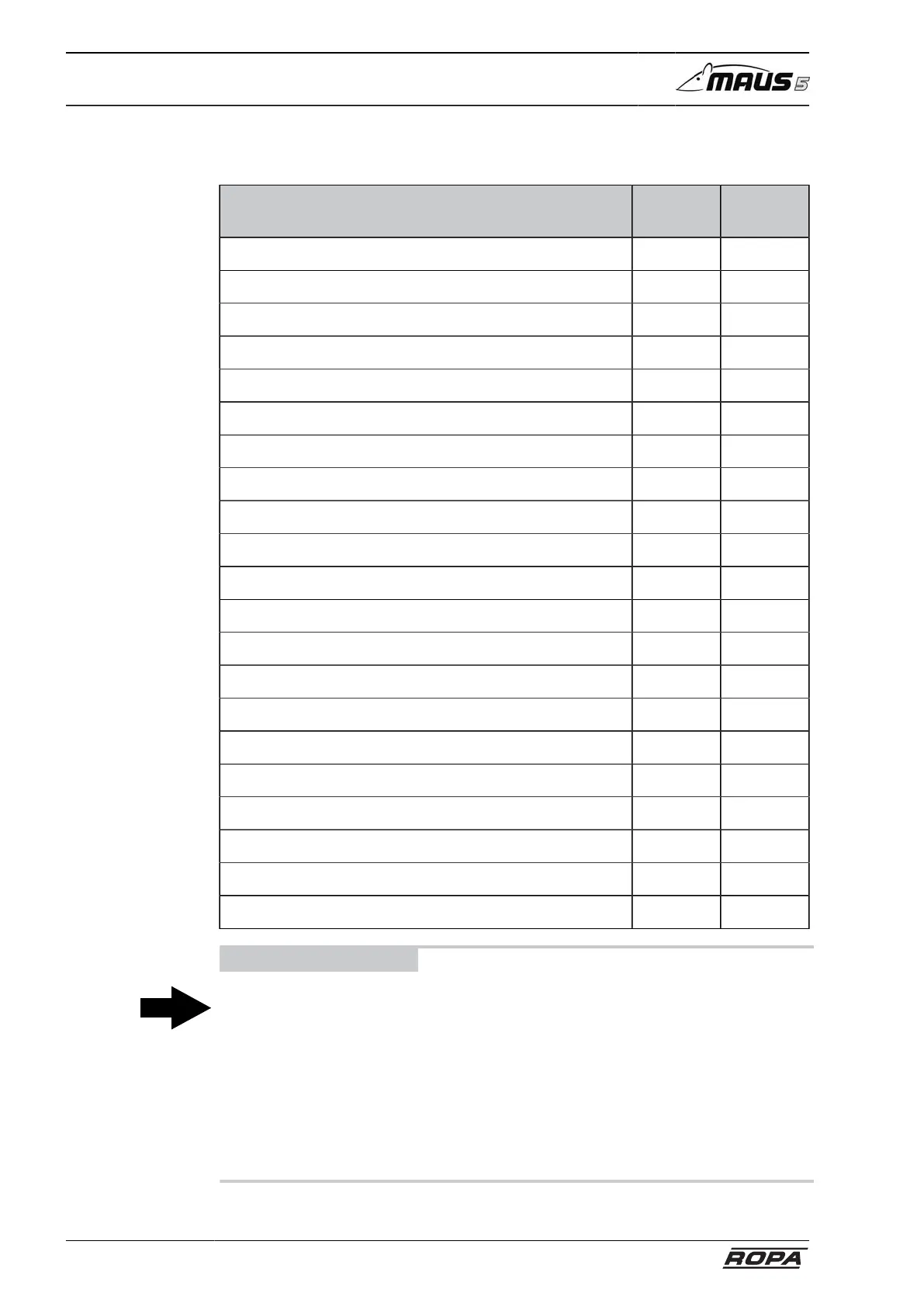

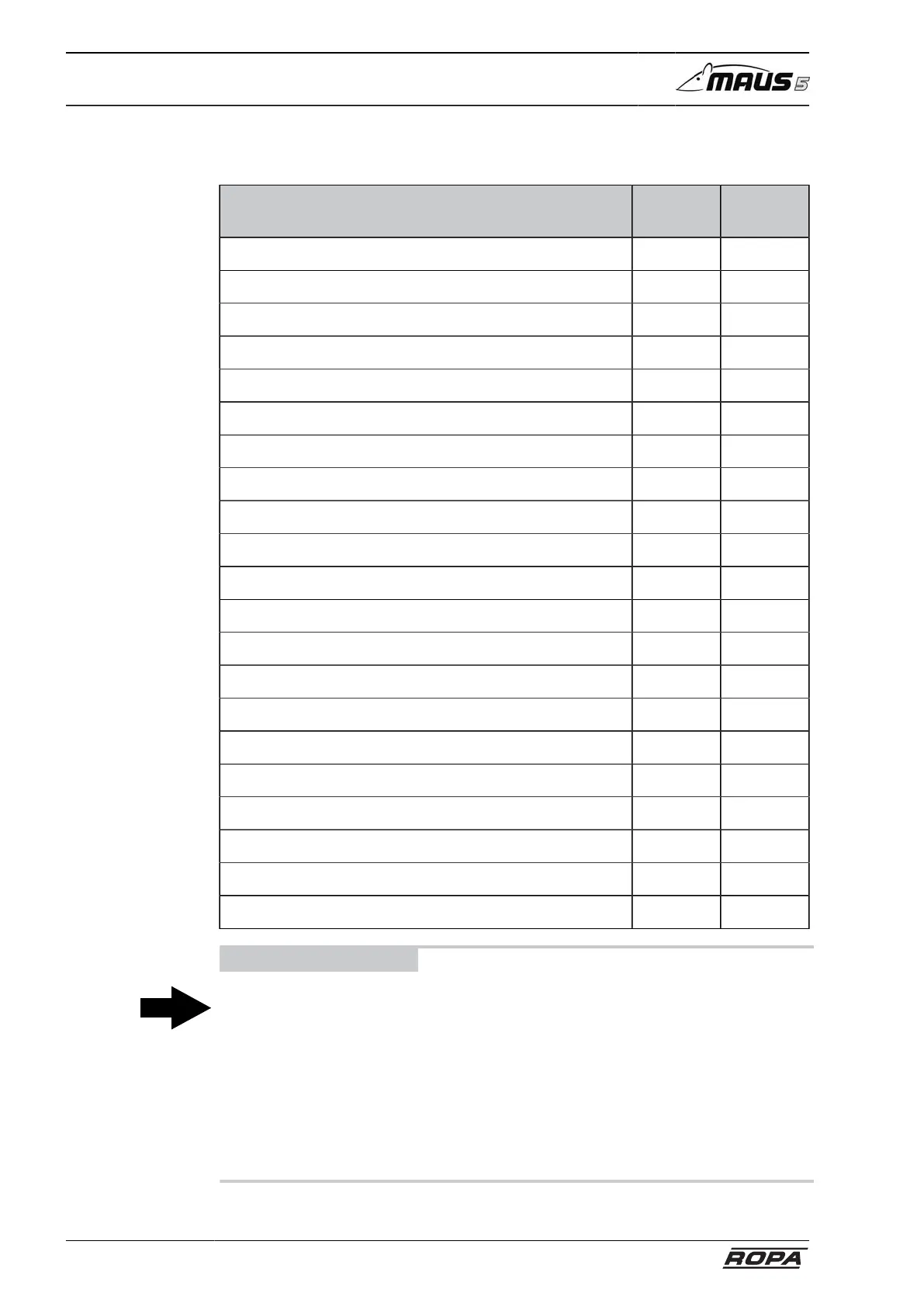

9.3 Lubricating plan (lubrication with grease gun)

Lubricating point Number of

nipples

Every

oper. hrs.

Telescopic pile pickup (coat with grease) 4 as required

Fold in pickup hydraulic cylinder joint head 2 100

Fold bolt on pickup cylinder 2 100

Lift up pickup hydraulic cylinder joint head 2 100

Support pivot left and right 2 100

Residual beet pickup pivot 2 100

Pile pickup hydraulic cylinder joint head right-left 4 100

Pile pickup hydraulic cylinder joint head up-down 2 100

Front additional axle self-steering 2 100

Cylinder axle support 4 100

Additional axles rear-front cylinder load 8 200

Locking lever swivel arm roller 1 200

Locking lever swivel arm pivot 1 200

Universal joints in front and rear axles 8 200

Cardan shafts from gearbox to axles 4 200

Nipple block beside tank support 8 200

Turn intermediate lever for residual beet pickup sensor 1 Annually

Counterweight arm locking lever 4 Annually

Underrun protective device pivot 2 Annually

Rear recleaner attachment 6 200

Rotate recleaner cylinder joint head 1 200

ADVICE

All lubricating points must also be lubricated after each washing of the machine. After

washing of the machine, the central lubrication system must also be lubricated using

at least 2 intermediate lubrication cycles.

Grease ROPA item no. 435062

as per DIN 51825, NLGI-class 2, type: KP2K-20,

at low outdoor temperatures KP2K-30.

No lubricating greases containing solid lubricants may be employed. Biologically

degradable greases are also admissible.

Loading...

Loading...