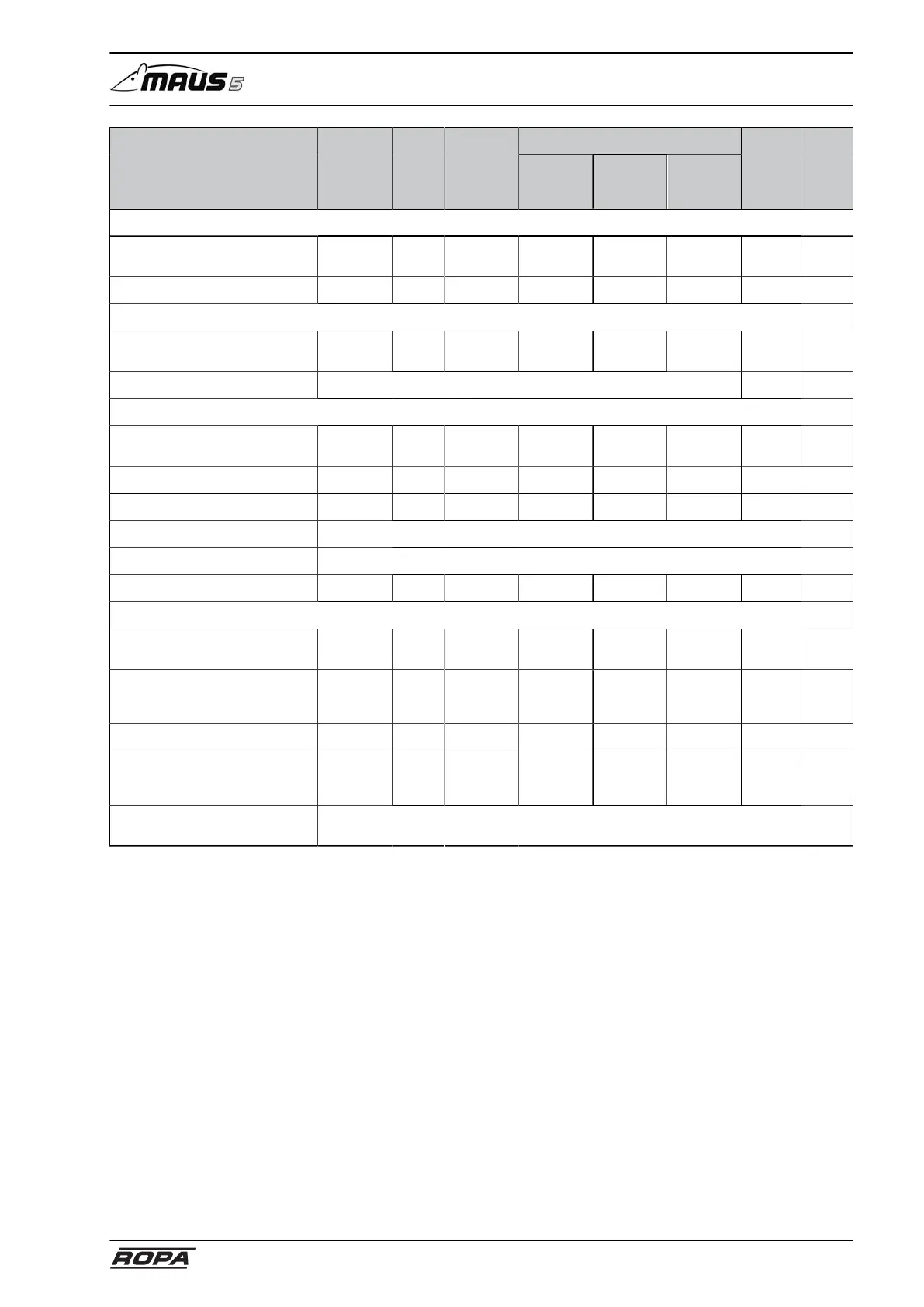

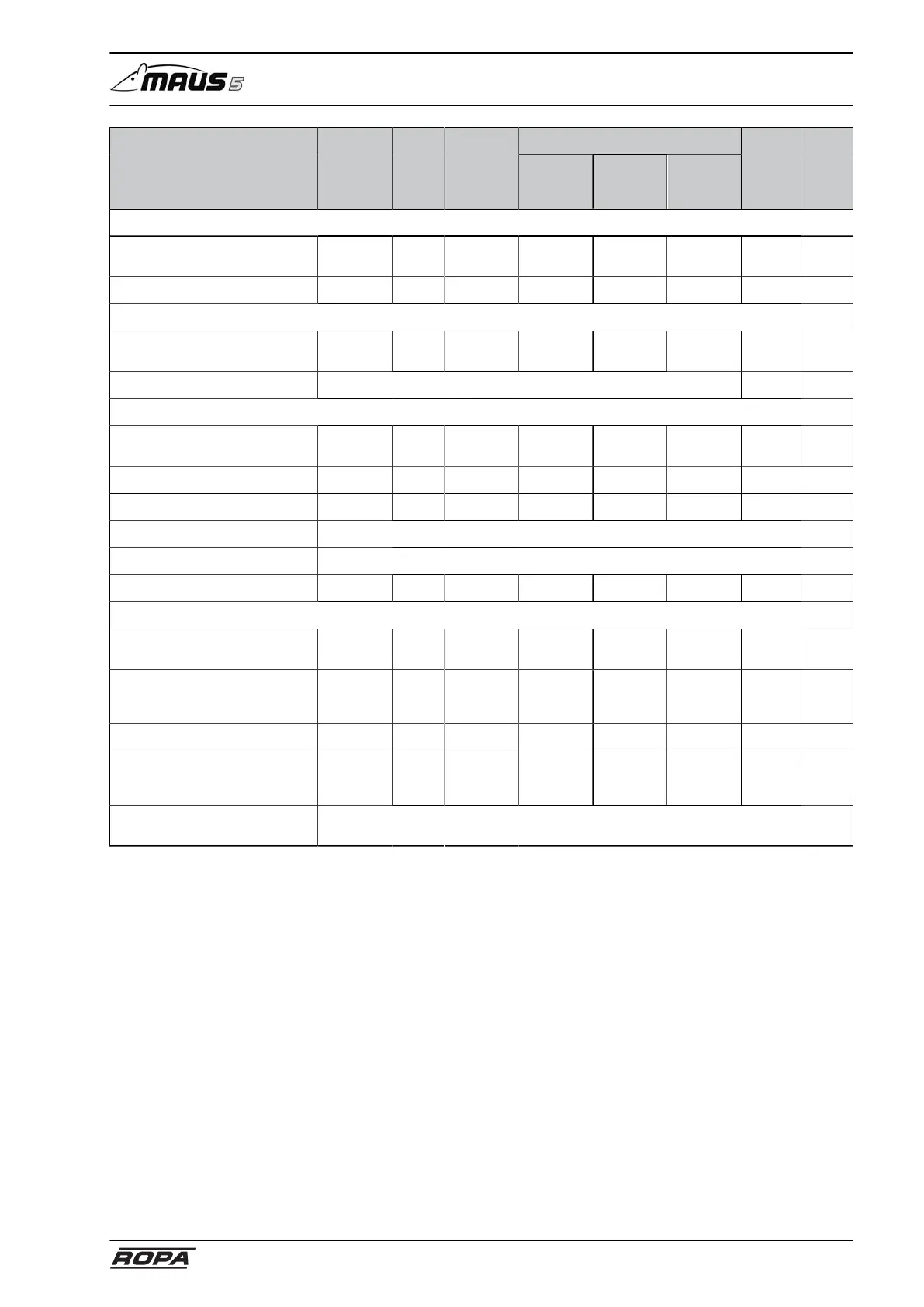

Lists/Tables/Plans/Diagrams/Maintenance Verification

Maintenance table

441 / 476

Maintenance interval

Maintenance work

before har-

vest

start

daily

after the

first 50

oper. hrs.

every 50

oper. hrs.

after the

first 500

oper. hrs.

every 500

oper. hrs.

when

needed

annu-

ally

Recleaner version 8-set pinch rollers

Check gear oil level in 8-set pinch roller

gearbox

X X

Change oil in 8-set pinch roller gearbox X X X

Truck conveyor

Check tension of sieve conveyor and

adjust if necessary

X X X

Replace drive wheels Depending on soil conditions every 80,000 - 180,000 t of loading X

all belts, conveyor tunnels and the remaining machine

Remove soiling

and sticking dirt

X X

check all rollers (do they rotate freely?) X

Refill grease container X

Grease lubricating points according to lubricating plan

Retighten wheel bolts 450 Nm after the first 10 and the first 50 oper. hrs.

Check tire pressure X X

Air conditioning system

Check condenser for soiling, possibly

clean

X X

Check hoses and lines for chafe marks

(visually), possibly have them

exchanged

X X X

Check coolant, possibly have refilled X X

Have the air conditioning system

checked by a qualified workshop and, in

case of need, repaired

X X

Have the collector drier and coolant

replaced

every 2 years

Loading...

Loading...