Lists/Tables/Plans/Diagrams/Maintenance Verification

Lubricating and operating supplies

437 / 476

9.1 Lubricating and operating supplies

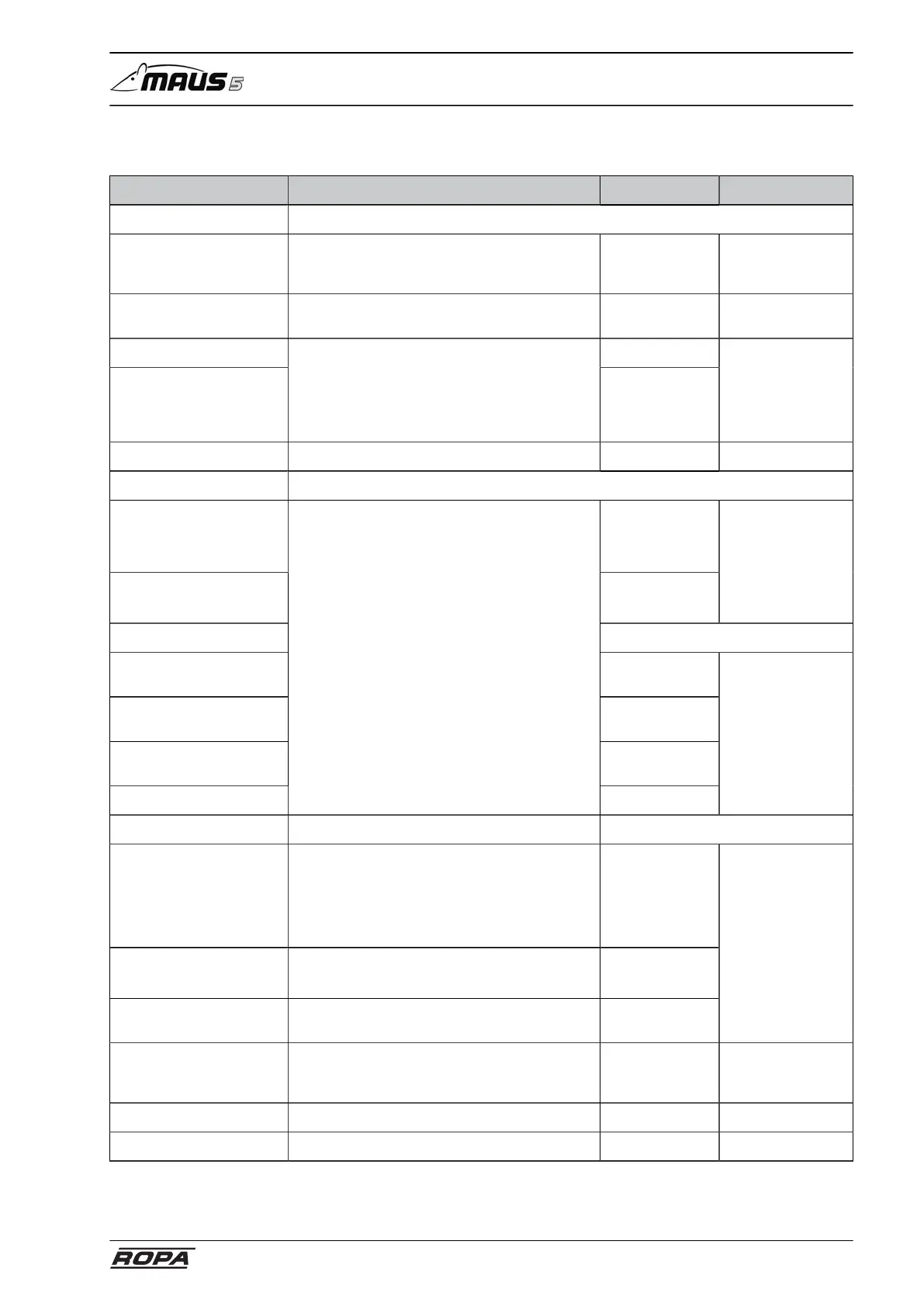

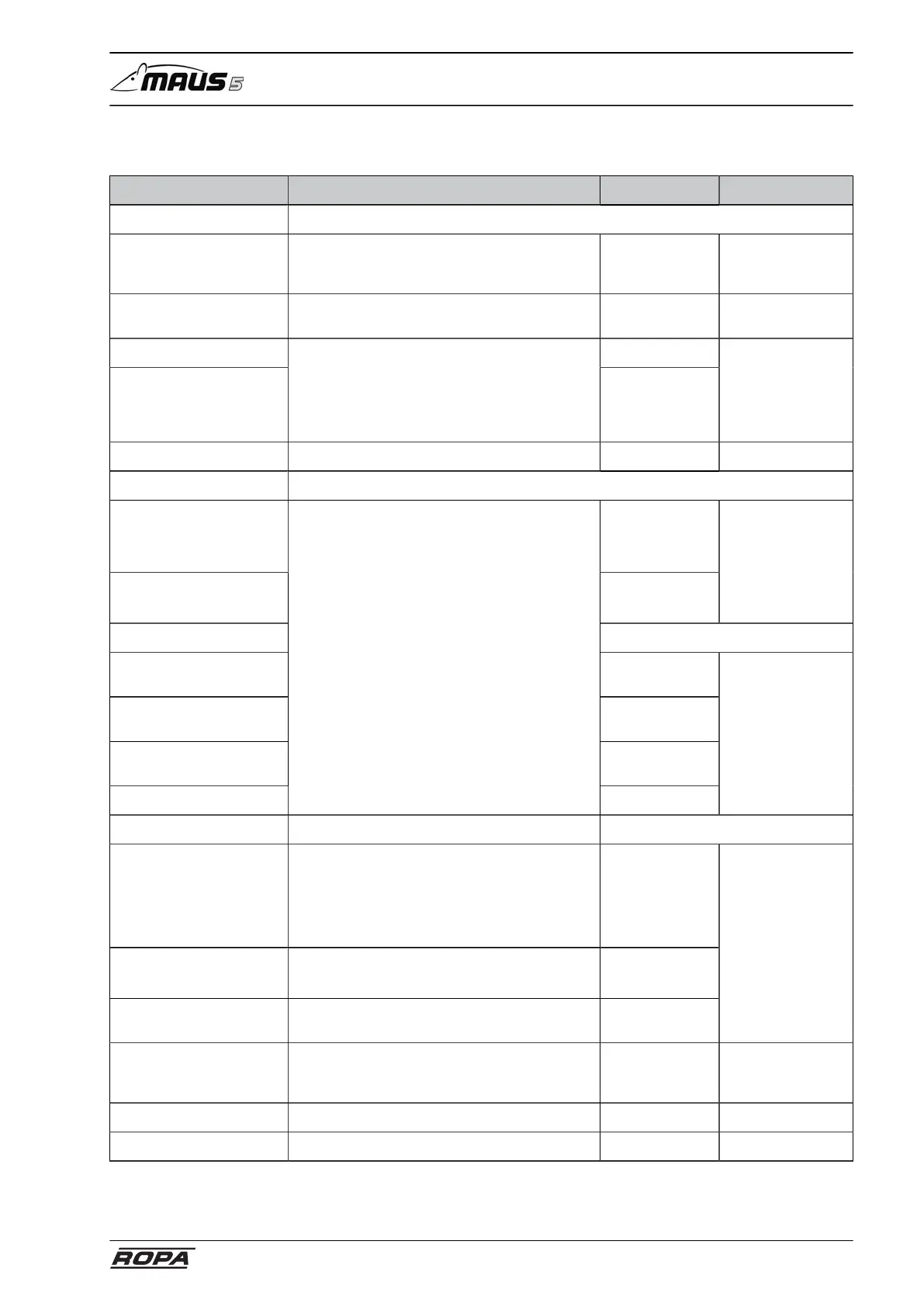

Component Lubricant type Filling volume: Intervals

Diesel engine OM 936

Engine oil

Engine oil, partially synthetic

multigrade oil as per MB standard 228.5

MB standard 228.51 is also permitted

approx. 27 litres every 500 oper. hrs.

Cooling system

Corrosion/antifreeze agent -40° as

per MB standard 325.5 and 326.5

approx. 25-30 litres every 3 years

Fuel tank approx. 1190 litres

Intermediate tank

Diesel fuel

DIN EN 590

(max. 0.001% sulphur by weight) (10 ppm)

ASTM D975

(max. 0.0015% sulphur by weight) (15 ppm)

approx. (35 litres)

when needed

AdBlue® tank AdBlue® DIN 70070 approx. 95 litres when needed

Axles

Differential gears

→ front axle

→ rear axle

approx. 22 litres

approx. 20 litres

Planetary gears

2 axles, 2 pcs. each

each approx.

3.5 litres

annually

Pickup/cleaning

Pickup rollers gears 2 pcs. each approx.

9.0 litres

Pickup rollers gears 2 pcs. each approx.

3.5 litres

Gears for 4 pinch rollers 2

pcs.

each approx.

1.4 litres

Gears for 8 pinch rollers

Gear oil

API GL 5, SAE 90

approx. 6.0 litres

annually

Others

4-gear manual transmission

Model with 1 traction drive

engine

Model with 2 traction drive

engines

Fully synthetic gear oil

API GL5, SAE 75W-90 as per ZF standard TE-ML 05B

approx. 12 litres

approx. 12.4 litres

Pump distributor gears

Gear oil ATF

ATF oil as per Dexron II D

approx. 10.0 litres

Hydraulic system

Hydraulic fluid HVLP 46 (containing zinc)

ISO-VG 46 as per DIN51524 part 3

approx. 190 litres

annually

Lubricating points

Grease

as per DIN 51825, NLGI class 2, type:

KP2K-20, at low outdoor temperatures KP2K-30

according

to lubricating plan

Air conditioning system Coolant and oil see page 378 when needed

Windscreen washer system Window frost protection approx. 20 litres when needed

The oil level control bolts and inspection glasses are decisive for the filling volumes!

Loading...

Loading...