Operation

First startup

97 / 476

This chapter provides all information for operation of the machine. For most work in

an agricultural area, the mode of working and the work results are under the influence

of many individual and different factors. The scope of this operating manual would be

exceeded if we have considered all conceivable situations (ground condition, sugar

beet varieties, weather, local land conditions, etc.). This operating manual cannot be

instructions for loading of sugar beets or replace driving instructions for driving on the

road. Preconditions for operation of this machine and for optimum harvest results are,

besides driver training offered by the manufacturer or service partner, solid basic agri-

cultural knowledge and some experience with growing sugar beets and the associ-

ated work processes. This chapter provides information about processes of operation

and coherences during operation of the machine. You will find an exact description of

adjusting work for the individual functional components in the respective chapters. The

required maintenance work is described in chapter 7, "Maintenance and Services".

ADVICE

Obtain comprehensive information about the safety measures for operation of this

machine before each operation of the machine. Should any people be present, who

are not informed about the applicable hazard zones and safety distances, then inform

these people about safety distances and hazard zones. Indispensably inform these

people that you will immediately shut down the machine as soon as anyone unautho-

rized comes close to the hazard zones.

6.1 First startup

For safety reasons, check all oil levels, the level of coolant fluid, the current fuel and

AdBlue level. Otherwise, all work and measures are required for first startup as they

must be performed for daily startup.

All bolted connections must be checked for tightness after the first 10 operating hours

and retightened in case of need. In addition, the complete hydraulic system must be

checked for leaks. Possibly existing leaks must be repaired immediately. Further-

more, all hose clips on coolant hoses, charge air hoses and air intake hoses must be

checked for tight fit and possibly retightened.

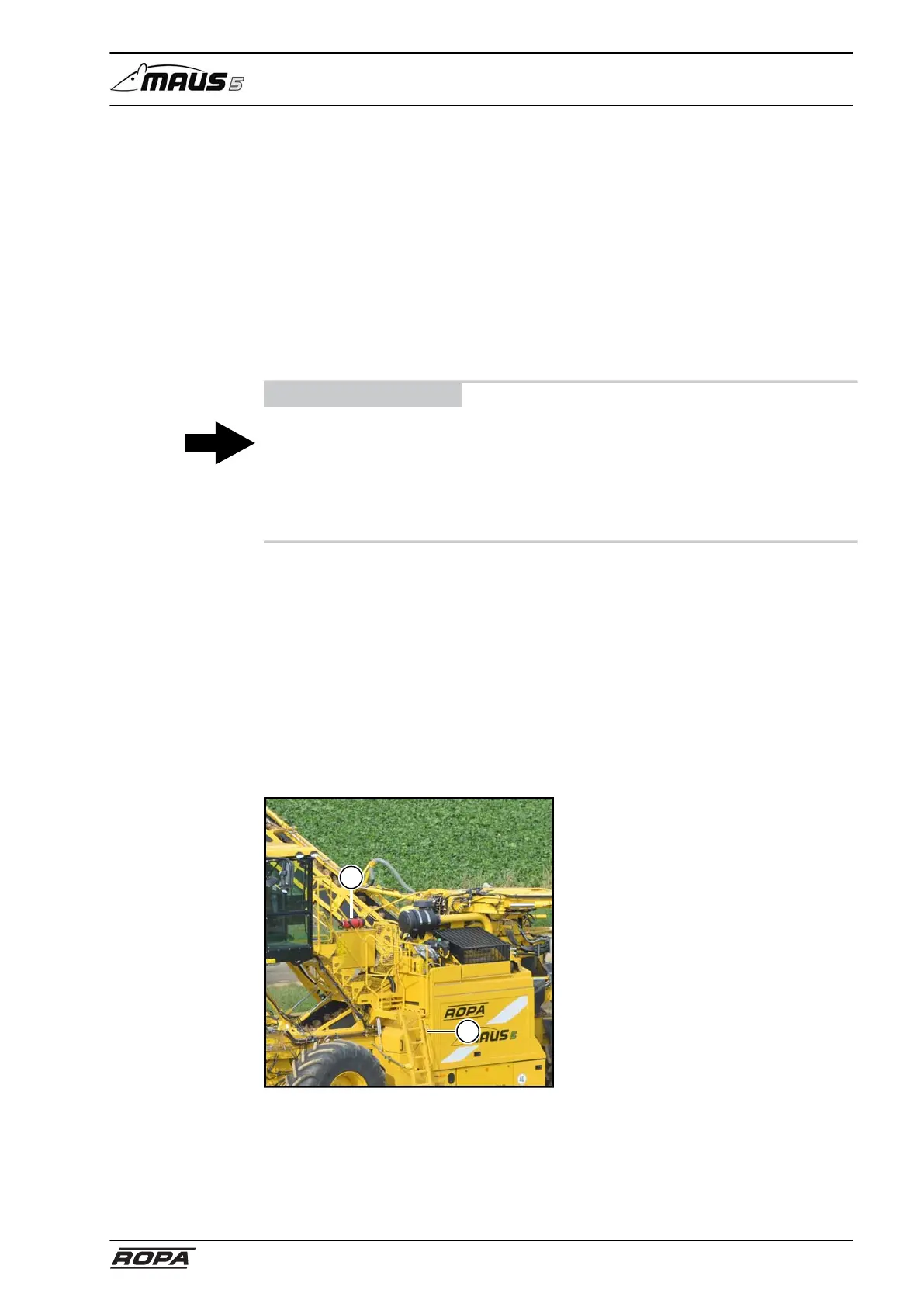

1

2

Stow the provided accessories,

such as fire extinguisher (1), wheel

chocks, cleaning scraper (2), tool box

in the pockets or brackets provided for

them.

Loading...

Loading...