Maintenance and Service

Hydraulic system

338 / 476

7.3.2 Replacing pressure filter element

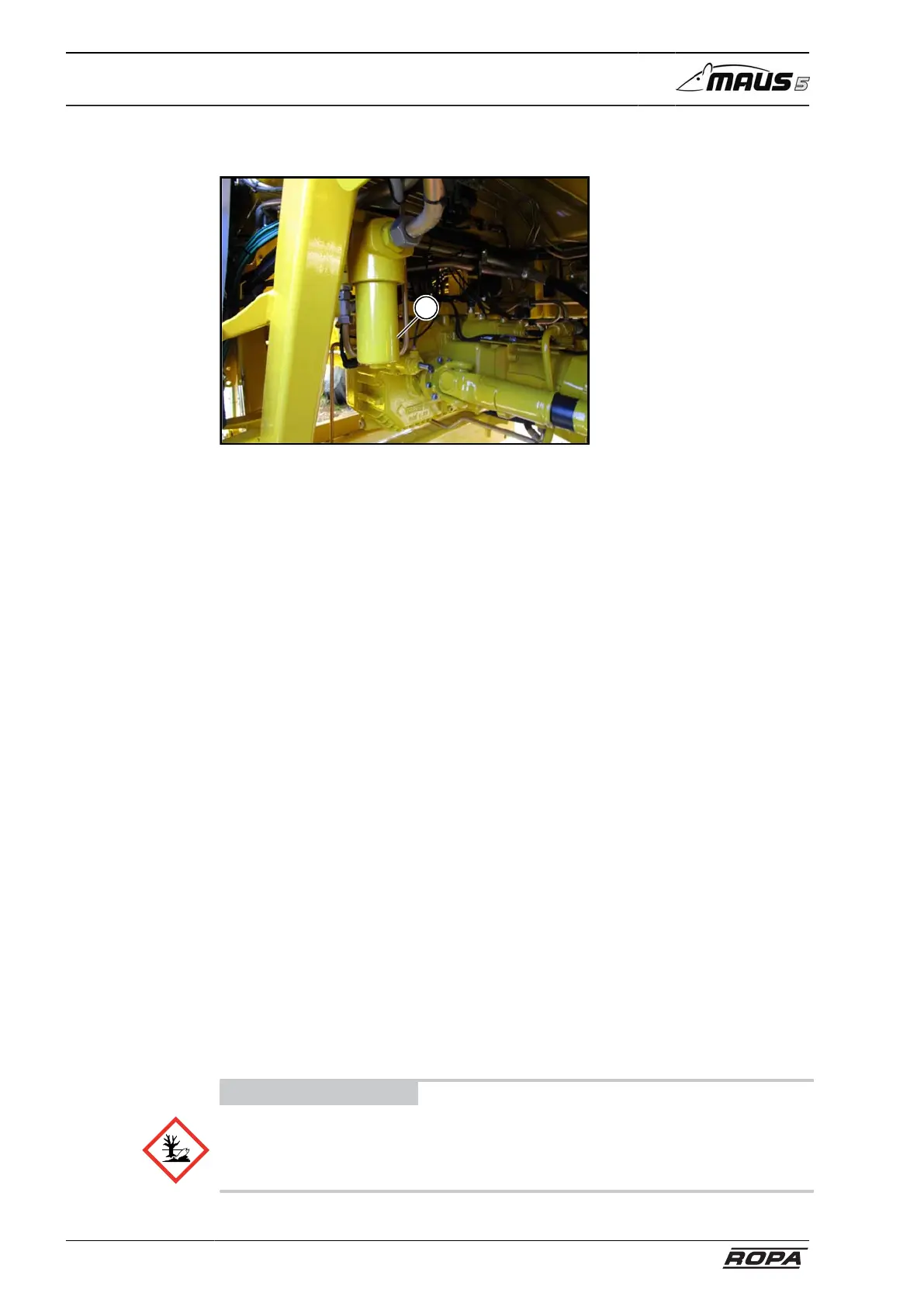

1

(1) Pressure filter operating hydraulics

Pressure filter operating hydraulics

The pressure filter for the operating hydraulics is located behind the AdBlue® tank.

First exchange of all filter element is required after the first 50 operating hours, there-

after, annually. Besides a fluid-resistant and sufficiently large catchment barrel, you

will need a ring wrench or fork wrench SW 32.

Filter exchange

– Shut down diesel engine.

– Unscrew the filter bowl. Catch the liquid in a suitable container and clean it respec-

tively dispose of it in an environmentally compatible manner.

– Pull the filter element from the element holding pin. After having removed the fil-

ter element, check if there is a metal end cap at the top. If this is not the case, pull

off the end cap separately from the element holding pin. Inspect the element sur-

face for dirt residue and larger particles. These may point to damage to the compo-

nents.

– Clean the bowl.

– Inspect the filter for mechanical damage; check sealing surfaces and threads in

particular.

– Exchange the O-ring on the filter bowl. Dirt or incomplete pressure relief during dis-

assembly may lead to seizing of the bowl screw thread.

Element installation

– Coat thread and sealing surfaces of the filter bowl and head as well as the O-ring

of the bowl and element with clean hydraulic fluid in case of need.

– Install a new element (ROPA item no. 270430).

– Carefully install the filter element on the element holding pin.

– Screw in the filter bowl to the stop.

– Unscrew the filter bowl by one sixth revolution.

– Start diesel engine and, for instance, raise the pile pickup to the stop (move against

pressure), check the filter for leaks.

ADVICE

Filter element must be disposed of in compliance with regional environmental protec-

tion regulations!

Loading...

Loading...