Operation

Loading operation

236 / 476

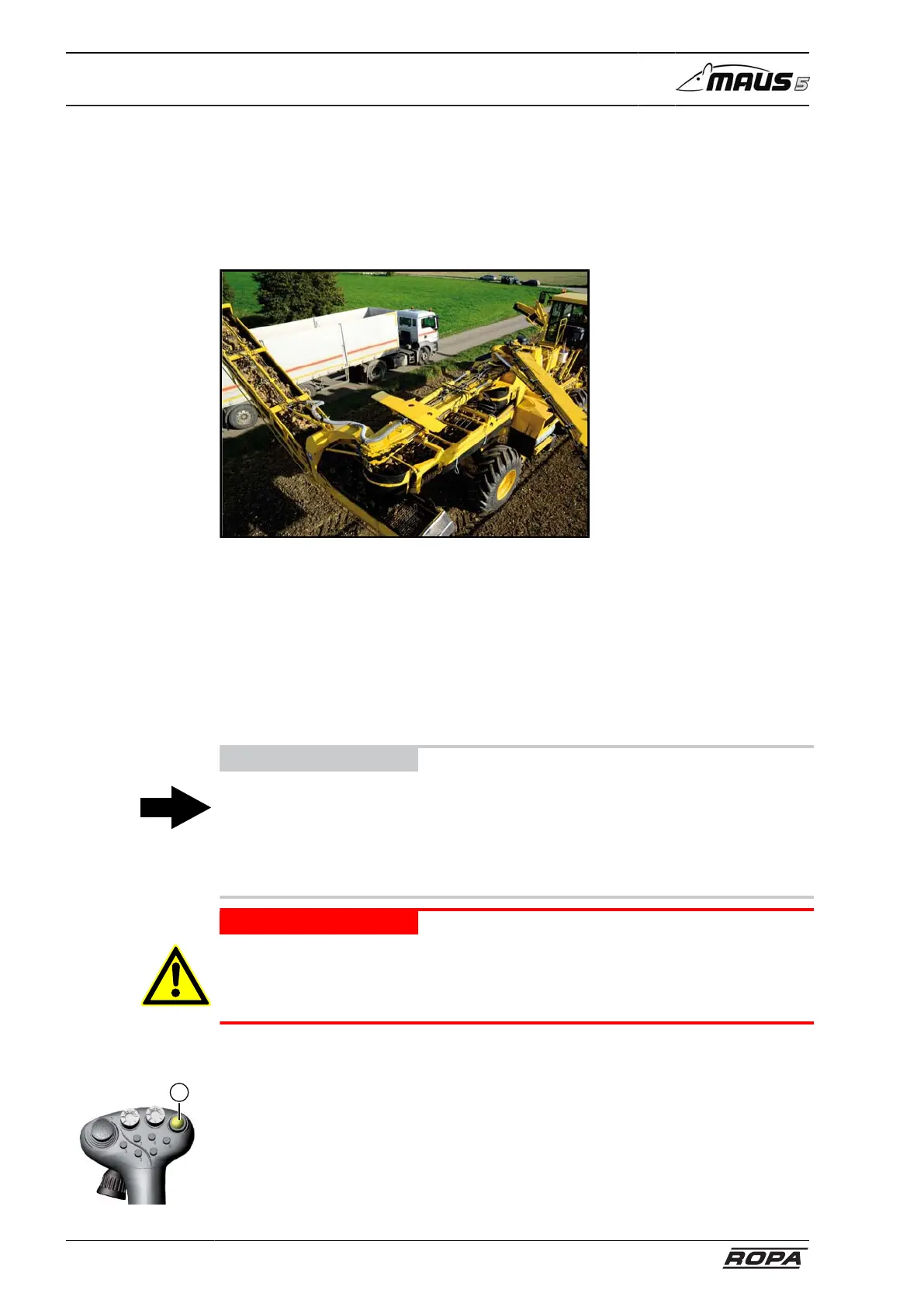

6.13.15 Loading truck

When loading trucks the following directions must be observed at all times to ensure

that the beets are handled as gently as possible during the loading process.

– Never change the direction of the beet flow between the infeed conveyor, preclean-

ing and truck conveyor by 90° or more.

gentle beet flow

– Adjust the complete beet cleaning process to be as gentle as possible (lowest pos-

sible speeds).

– Work at the lowest possible diesel engine speed (1200-1300 rpm) to save fuel and

protect the environment.

– Do not allow the beets to fall into the load compartment of the truck any higher than

necessary. Always lower the truck conveyor as much as possible and when start-

ing loading insert the articulation as low as possible between the side walls of the

truck.

ADVICE

Important!! The rotary motions of the swivel arm and truck conveyor are actuated by

chain drives. During operation watch the movement to ensure that they are always

correct and that the chains are correctly tensioned. The chains are automatically ten-

sioned by the hydraulic system.

The machine must be stopped immediately if the chains are not correctly tensioned.

DANGER

Risk of fatal injury due to uncontrolled swivel motions of swivel arm and truck

conveyor if the chain on the rotary drive skips.

– Stop the machine immediately and have the machine checked by a mechanic.

6.13.16 After-loading function

6

If the operator wishes to load a small volume of sugar beets on the truck after shutting

down the machine, this is easily done with the after-loading function.

After-loading is always performed at a permanently programmed low engine speed on

which the driver has no influence.

Press and hold the yellow machine drive ON/OFF key (6) on the right joystick and

keep it pressed until the desired volume of sugar beets has been loaded. The drive

stops as soon as the key is released.

Loading...

Loading...