Operation

Scales (option)

256 / 476

6.15 Scales (option)

6.15.1 Structure and function

An electronic conveyor scale is used. It weighs the load with the dirt content – referred

to in general as sugar beets – transported to the truck by the conveyor with highly sen-

sitive electronic load cells. The accuracy of every single weighing process is primarily

influenced by the correct operation of the scales and is not subject to the influence of

the manufacturer.

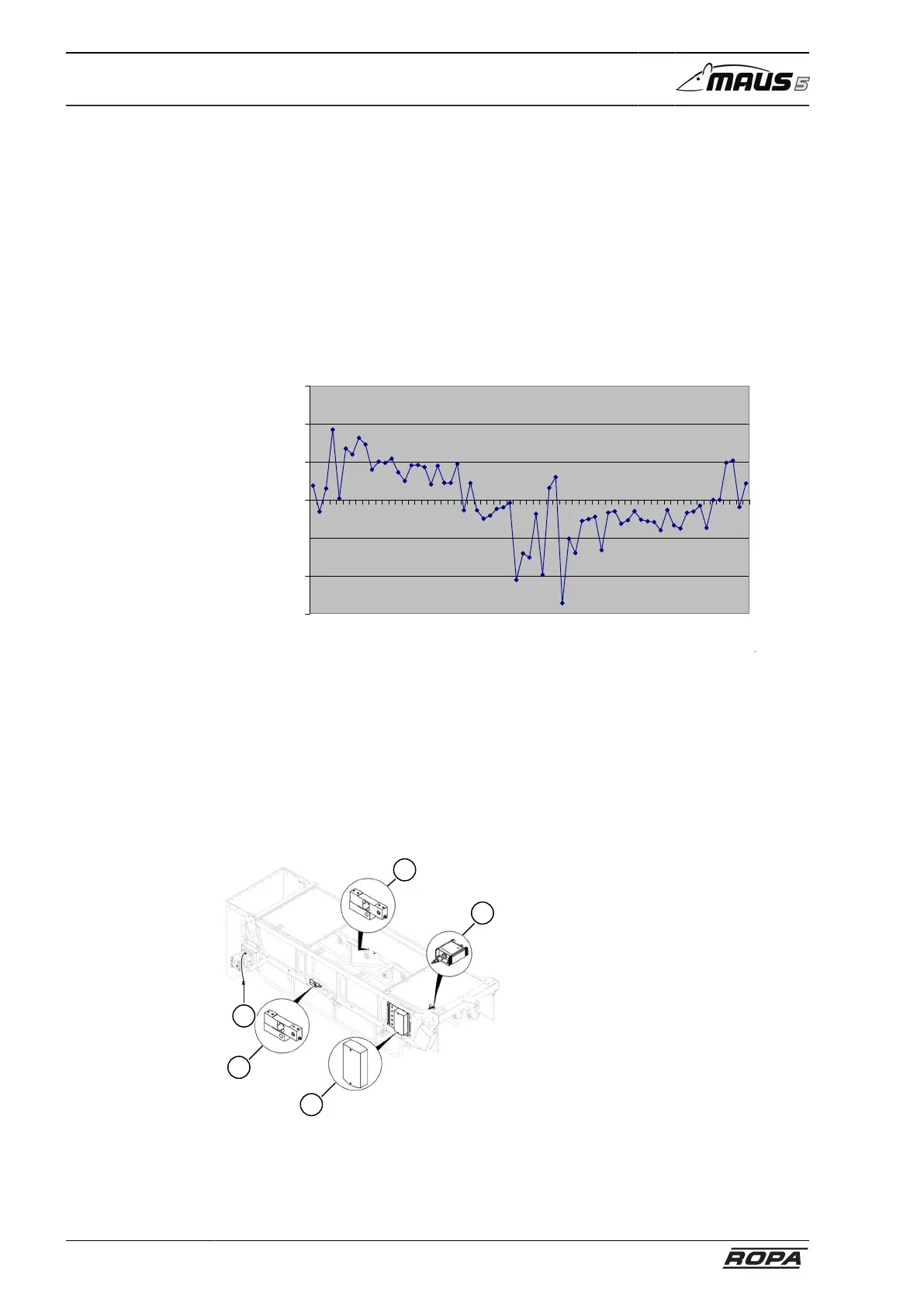

Deviation in the load sequence

-3.00%

-2.00%

-1.00%

0.00%

1.00%

2.00%

3.00%

Truck load 1-67

% difference

1 5 9 13 17 21 25 29 33 37 41 45 49 53 57 61 65

Optimal weighing results with 67 consecutive loads

In addition to correct operation, the following factors also have a significant influence

on the accuracy of the weighing process

– Ground characteristics

– Degree of contamination of the sugar beets

– Degree of contamination of the weighing rollers and the rollers immediately in front

of and behind the weighing roller

– The inclination angle of the truck loader articulated section

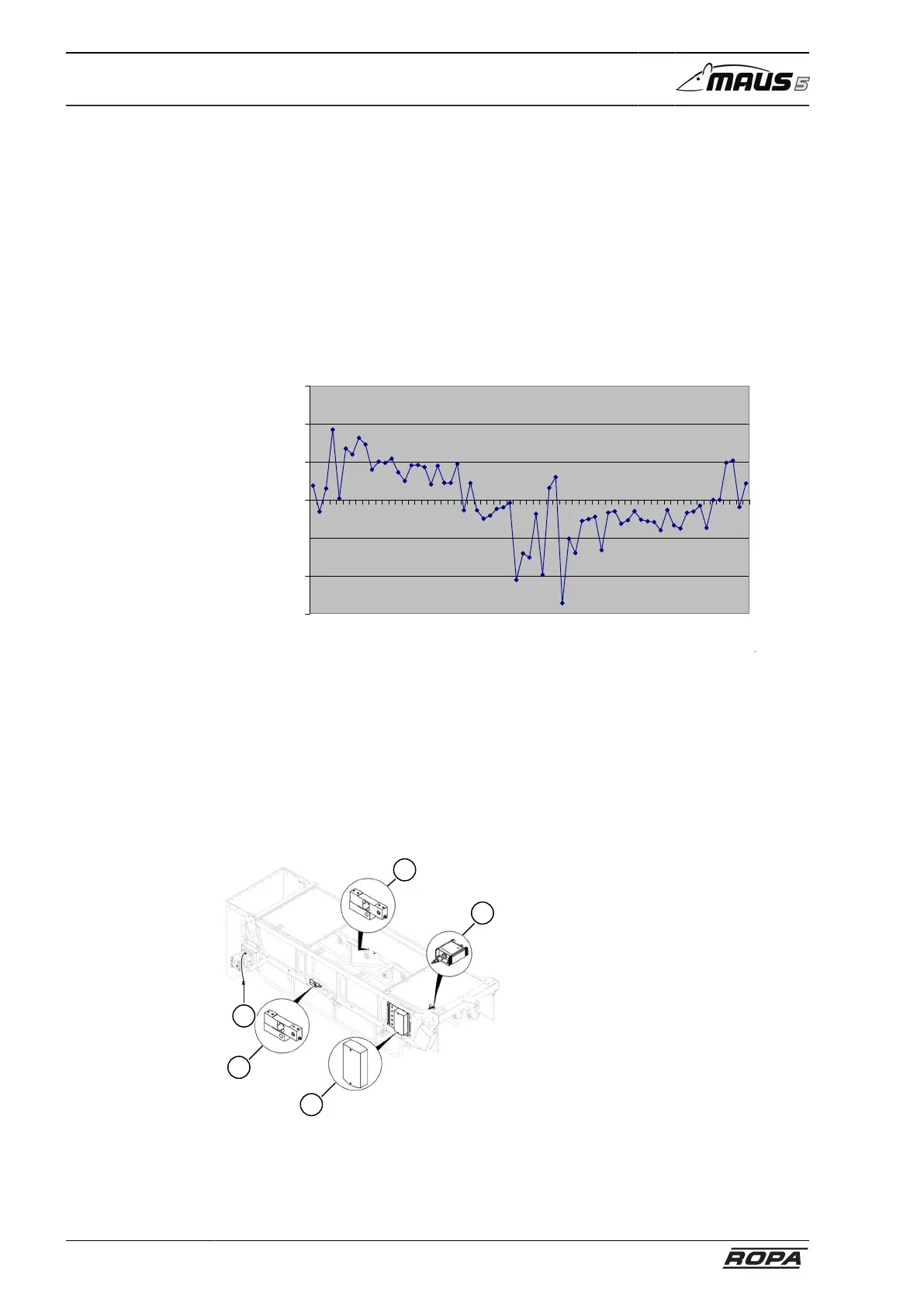

4

2

2

3

1

(1) Rotation speed sensor

(2) Weighing cell

(3) Computer

(4) Inclination sensor

Loading...

Loading...