Malfunction and Remedies

Emergency operation ventilator drives

428 / 476

1

(1) Safety valve

– Search for the blocked spot in the pipe system. Go along the stiffer grease pipe

from the lubricating pump through to the main distributor (the blocked pipe is stiffer

because it is under pressure) further to the corresponding sub-distributor and from

there to the blocked lubricating point. You can find a detailed plan in chapter 9.

– Disconnect the pipe from the distributor and screw a lubricating nipple into the cor-

responding (sub) distributor.

– Try to loosen the block strongly pressing grease into the distributor using the hand

lever grease gun.

– Proceed systematically: from the grease pump to the main distributor, from there to

the sub-distributor, etc..

Lubricat-

ing pump

→

Main distributor

→

Sub-distributor

→

Lubricat-

ing point

– Once you determine that the line is permeable again, connect the line with the con-

sumer. Check the free passage by performing an intermediate lubrication. (see

page 277)

– Shouldn't the method prescribed here lead you to any success, please contact your

ROPA service station.

Some distributors are provided with a lubricating nipple. This lubrication nipple is used

to simplify troubleshooting.

All lubrication points of the sub-distributor can be supplied with grease via this lubricat-

ing nipple, as a check valve is situated in the outflow of the main distributor.

There is no check valve between the lubricating pump and the main distributor.

You can recognize the main distributor on the integrated indicator pin display. Should

you feel only slight resistance when greasing the lubricating nipple at the main distrib-

uter, then the grease can flow freely into the grease reservoir of the central lubrica-

tion pump. In this case the wing in central lubrication pump must be turned by approx.

120° via manual intermediate lubrication.

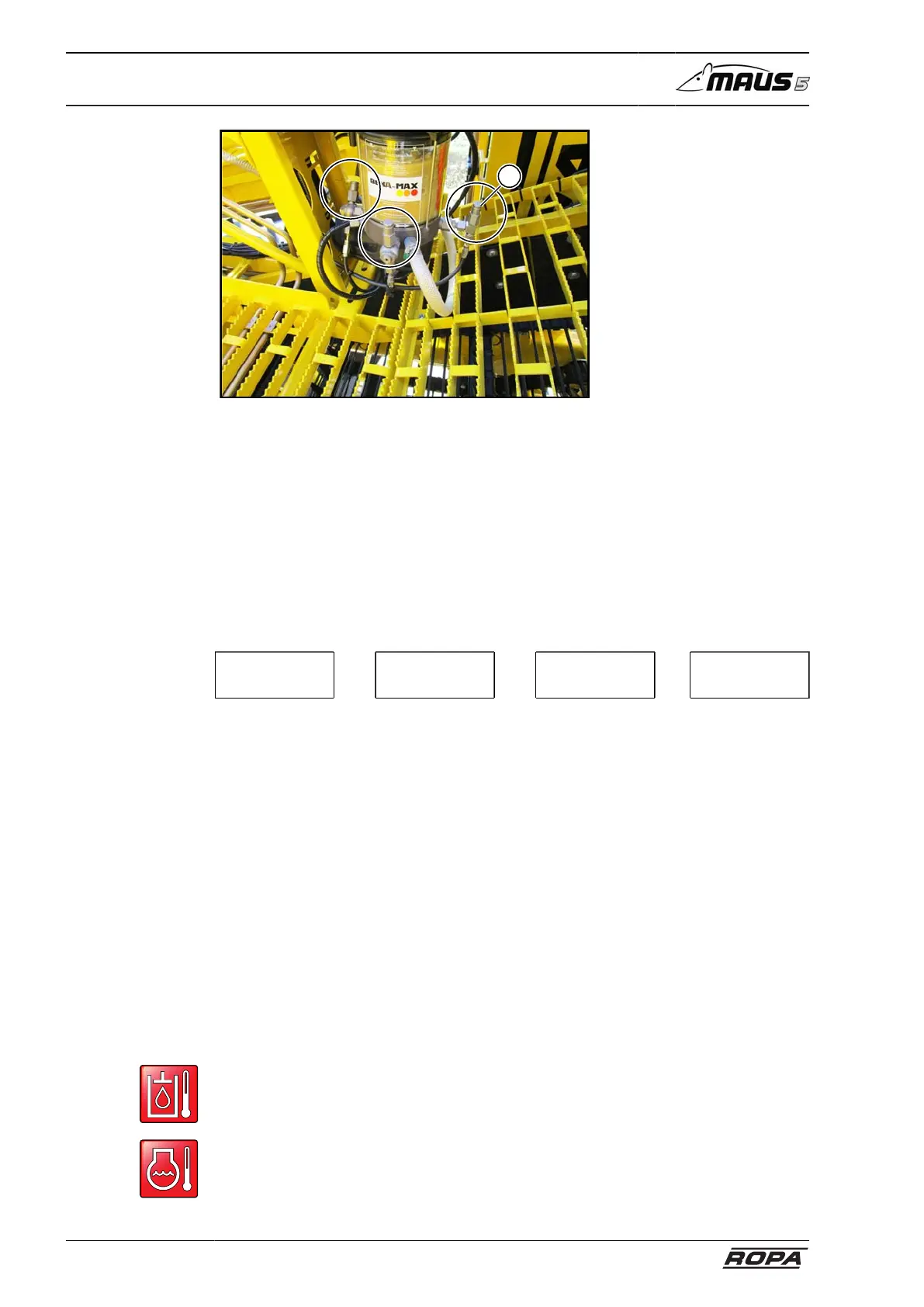

8.14 Emergency operation ventilator drives

To check whether the fan wheel of the cooling system is really running at maximum

speed, the plug (1) labelled "Y99" can be removed from the hydraulic pump as a test.

Then, the ventilator should be running at maximum speed.

If the cooling performance is not improved by this measure, then the machine may

only be operated at reduced load.

Loading...

Loading...