Operation

Central lubricating system

275 / 476

6.19 Central lubricating system

The machine is fitted with a central lubricating system and has two lubricating circuits

in the model with sieving conveyors cleaner or three in the model with 8-set pinch

rollers cleaner.

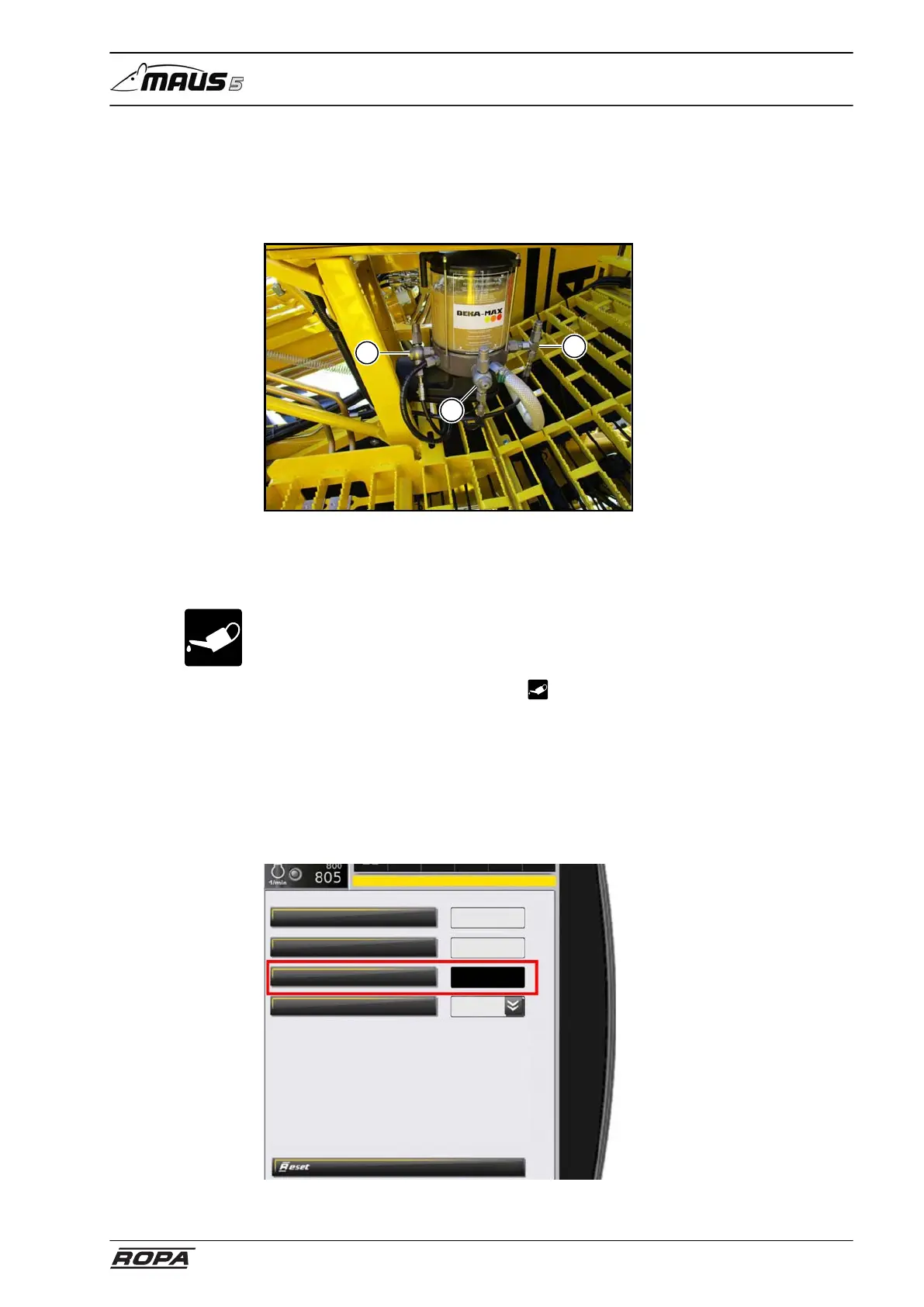

1

3

2

(1) Lubricating circuit 1 support

(2) Lubricating circuit 2 chassis

(3) Lubricating circuit 3 8-set pinch rollers cleaner

All connected lubricating points are automatically supplied with grease. The lubricating

pump supplies the grease to the main distributors, the main distributors distribute the

grease to sub-distributors, and these supply it to the individual lubricating points. As

long as the lubricating pump is running, a stirring paddle is rotating in the grease reser-

voir and the R-Touch displays the icon .

Every time the machine drive is switched on the lubrication pump is switched on for

the period that the operator has selected in the "Main settings" menu. The factory set-

ting for this period is 210 seconds. The driver can extend the period to a maximum

300 seconds.

We recommend setting the lubrication period to 180 seconds (pump operating time)

for loading up to 20 tons per delivery unit. When loading delivery units up to approx. 28

tons we recommend a pump operating time of around 210 seconds, and correspond-

ingly longer times for larger delivery units.

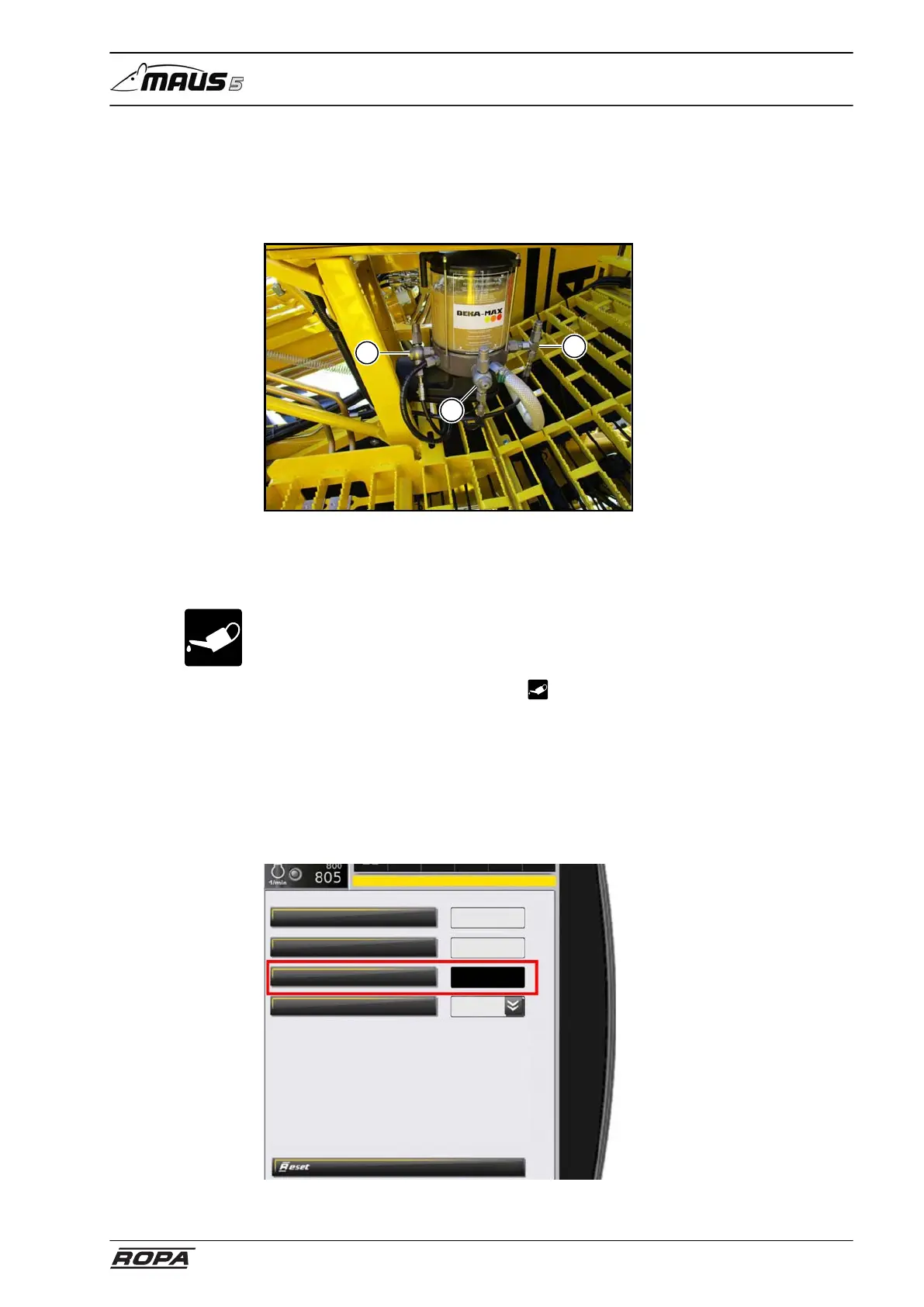

Main settings

Fuel reserve warning %

AdBlue reserve warning %

Greasing time (sec)

Reverse-automatic rollers

20

15

210

On

210

Loading...

Loading...