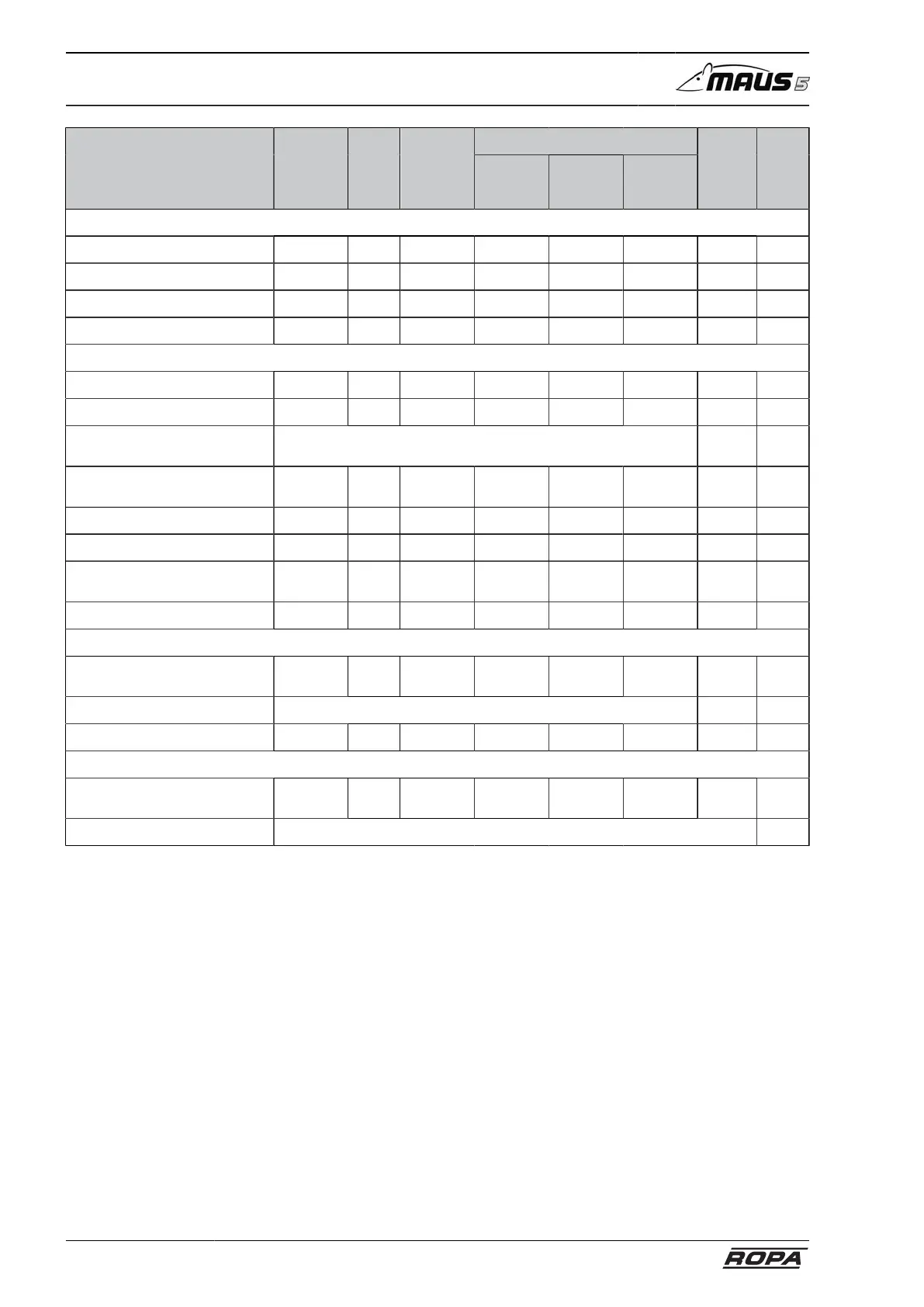

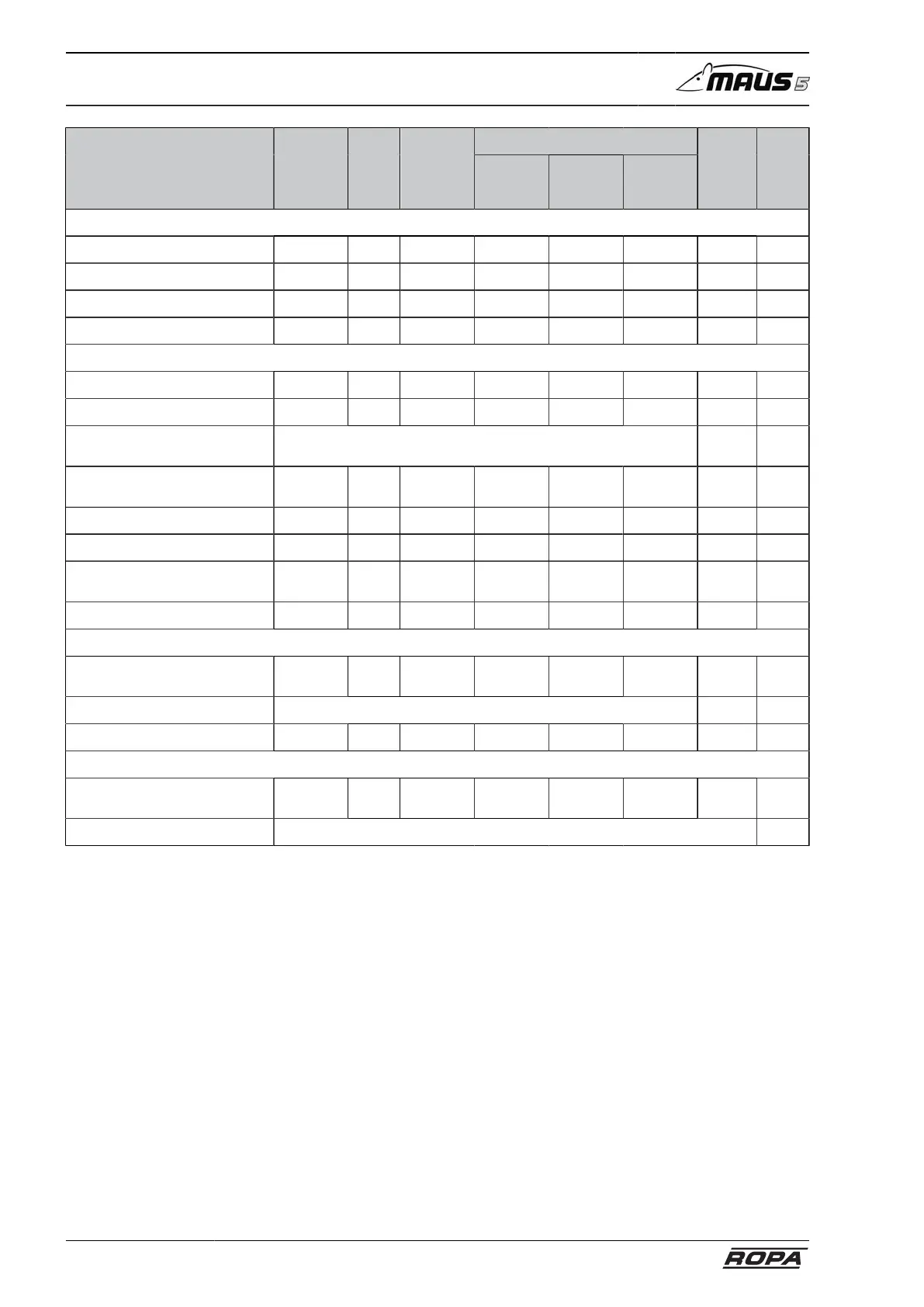

Lists/Tables/Plans/Diagrams/Maintenance Verification

Maintenance table

440 / 476

Maintenance interval

Maintenance work

before har-

vest

start

daily

after the

first 50

oper. hrs.

every 50

oper. hrs.

after the

first 500

oper. hrs.

every 500

oper. hrs.

when

needed

annu-

ally

Driver's cabin

Clean recirculating air filter X

Replace recirculating filter X

Clean fresh air intake filter X X

Renew fresh air intake filter X

Pickup

Check oil level in pickup rollers gearbox X X

Changing oil pickup roller gearbox X X X

Replace radial shaft seal in the bearing

on the gearbox side

every 300,000 t of load

X

Replace hexagon screws (M20 x 360) in

the pickup roller

X X

Check gear oil level in conveyor rollers X X

Change oil in conveyor roller gearbox X X X

Check gear oil level in 4-set pinch roller

gearbox

X X

Change oil in 4-set pinch roller gearbox X X X

Infeed conveyor

Check and if necessary adjust deflection

roller scraper

X X

Replace drive wheels Depending on soil conditions every 60,000 - 140,000 t of load. X

Check tension and adjust if necessary X X

Recleaner version sieve conveyor

Check tension of sieve conveyor and

adjust if necessary

X X

Replace drive wheels Depending on soil conditions every 100,000 - 200,000 t of loading

Loading...

Loading...