Section 05 ENGINE (4-TEC)

Subsection 02 (INTAKE SYSTEM)

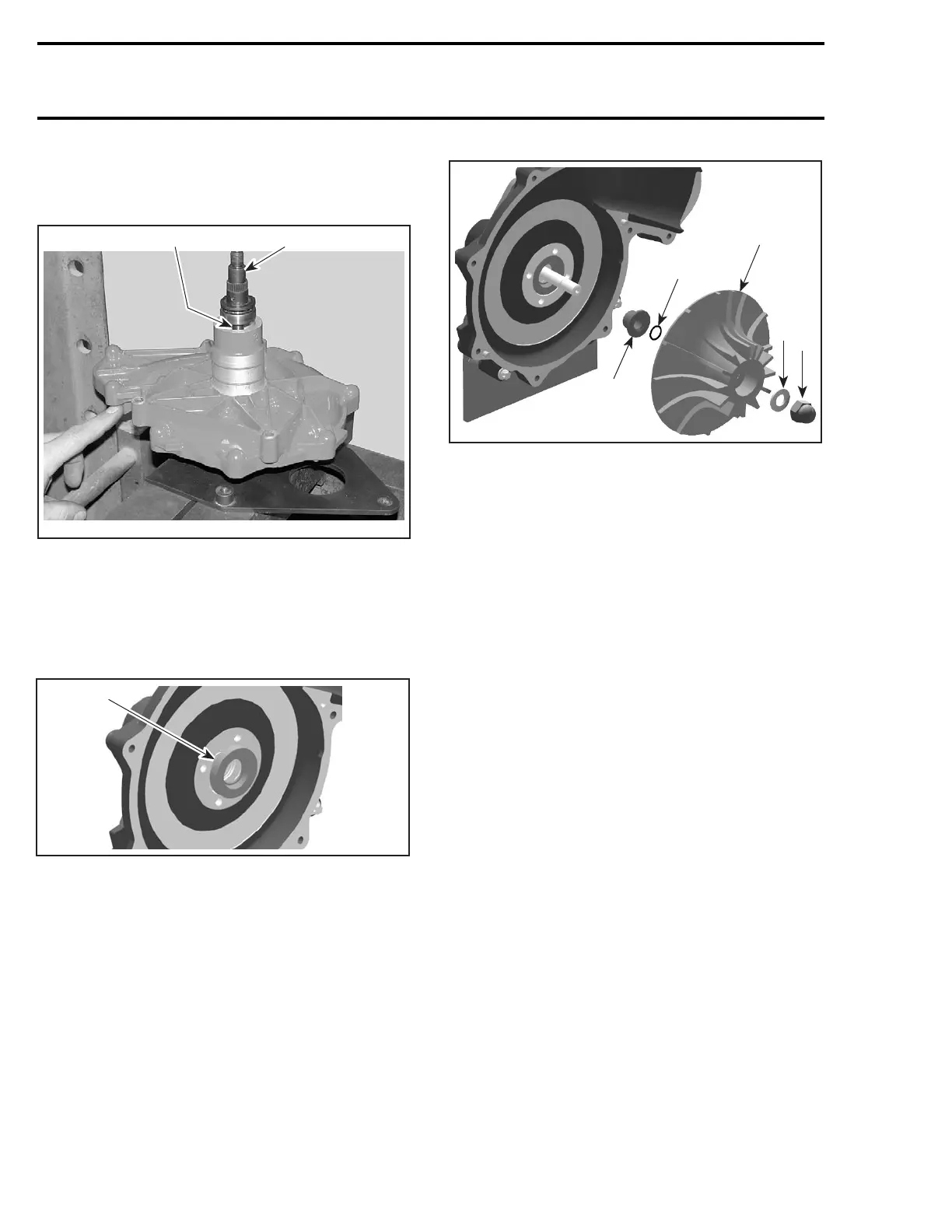

Apply engine oil on supercharger shaft. Press

shaft with distance sleeve together in supercharg-

er housing half.

1

F00B2HA

2

1. Supercharger shaft

2. Distance sleeve

Applyengineoilonsealandpushintoretaining

disc by hand.

NOTE: Always use a new oil seal when assem-

bling the supercharger.

1

R1503motr242A

1. Oil seal

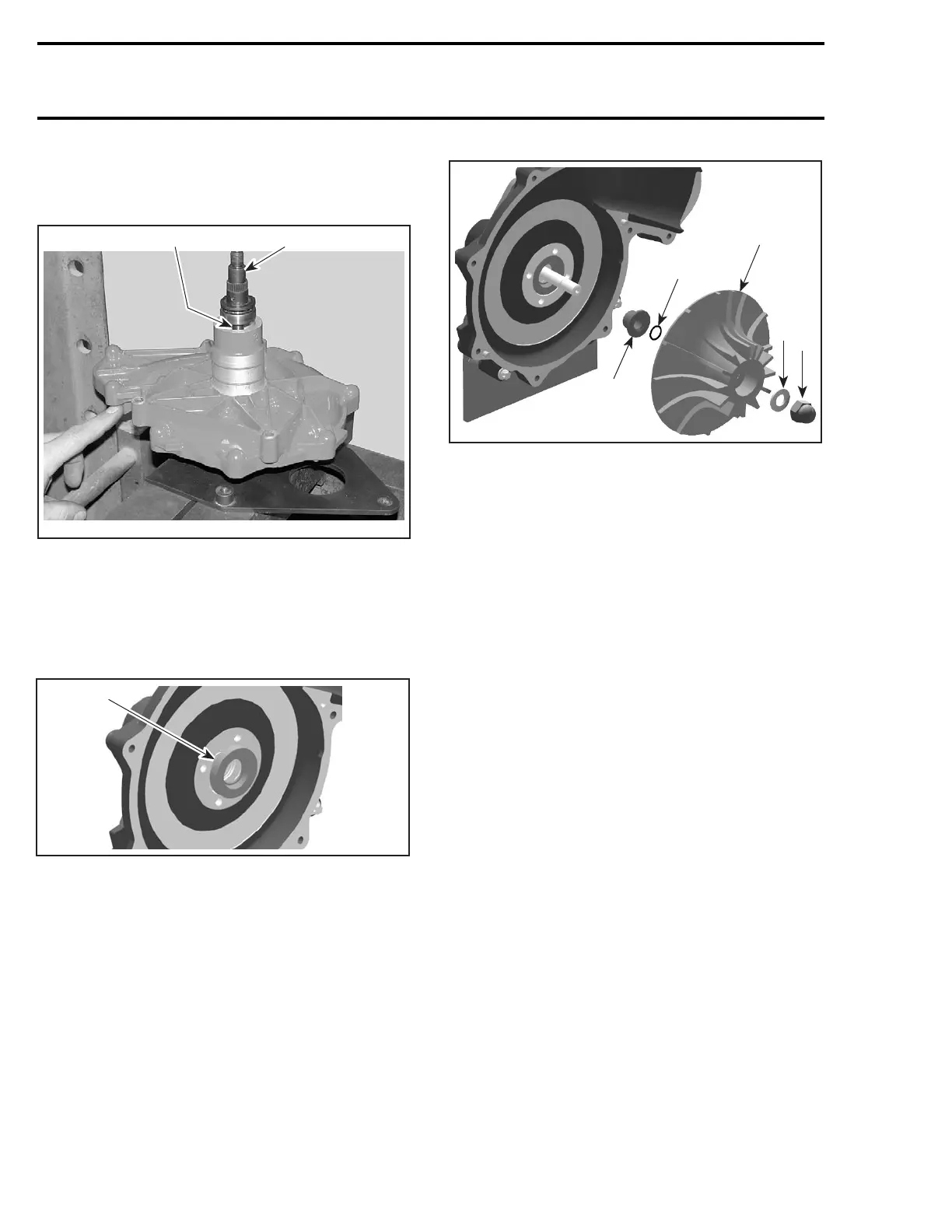

Install step collar, O-ring, supercharger impeller

and washer on supercharger shaft. Apply Loctite

243 on cap nut and temporary finger tight cap nut.

NOTE: The cap nut on the supercharger shaft has

a left-handed thread. The Loctite has to be appli

ed

in a small dose into the nut.

4

R1503motr229B

3

2

1

5

1. Step collar

2. O-ring

3. Supercharger impeller

4. Washer

5. Cap nut

Complete installation of supercharger shaft, en-

gine side as follows:

CAUTION: It is of the utmost importance that

all parts be absolutely clean. The compressor

shaft spins at up to 45 000 RPM and any debris

could cause a failure.

Install the first ceramic washer.

NOTE: On the RXP 4-TEC supercharged inter-

cooled engine, the ceramic washers differ in their

inner diameter. Install first the ceramic washer

with the bigger inner diameter. The ceramic

washer with the smaller inner diameter will be

installed on the lock washer side.

CAUTION: Manipulate ceramic washers with

care, those parts are fragile.

IMPORTANT: Apply Kluber Isoflex grease

(P/N 293 550 021) to the inner diameter of

the gear thrust surface on the shaft, ceramic

washers, needle bearings shaft surface and lock

washer.

CAUTION: No other grease can be used, other-

wise damage to bearings will occur.

Install the 40 needle bearings on the compressor

shaft.

NOTE: The 40 needle bearings comes in a wax

strip with an adhesive backing.

Remove the adhesive backing.

Install the drive gear over the needle bearings.

Install the other ceramic washer.

204 smr2004-Complete Line Up

Loading...

Loading...