Section 04 ENGINE (2-STROKE)

Subsection 07 (EXHAUST SYSTEM)

Tip seat forward.

Unfasten fuel tank straps.

Move fuel tank forward as much as possible.

Push muffler forward, rotate and pull out rear-

ward.

All Models

Pull muffler no. 11 outofbilge.

TUNED PIPE REPAIR

This procedure is given to repair tuned pipe cracks

using T.I.G. welding process.

Procedure

– Sand the cracked area to obtain bare metal.

– Perform a 1.50 mm (1/16 in) depth chamfer over

crack.

– Use pure argon gas with 5.55 mm (3/32 in)

tungsten electrode (puretung “green”, zirtung

“brown”) and AC current.

– Use a 5.55 mm (3/32 in) aluminum welding rod

(no. 4043), to fill crack.

– Sand welding slightly to remove material sur-

plus.

Test

– Usecompressedairat124kPa(18PSI)topres-

surize tuned pipe.

CAUTION: Always ensure water passages are

not blocked partially or completely while weld-

ingtunedpipe.

NOTE: Prior to verify leaks, plug all holes and pres-

surize tuned pipe while immerging it in water.

INSTALLATION

Installation is essentially the reverse of removal

procedures. However, pay particular attention to

the following.

Exhaust Manifold

Make sure gasket(s) no. 16 are properly posi-

tioned prior to finalizing manifold installation.

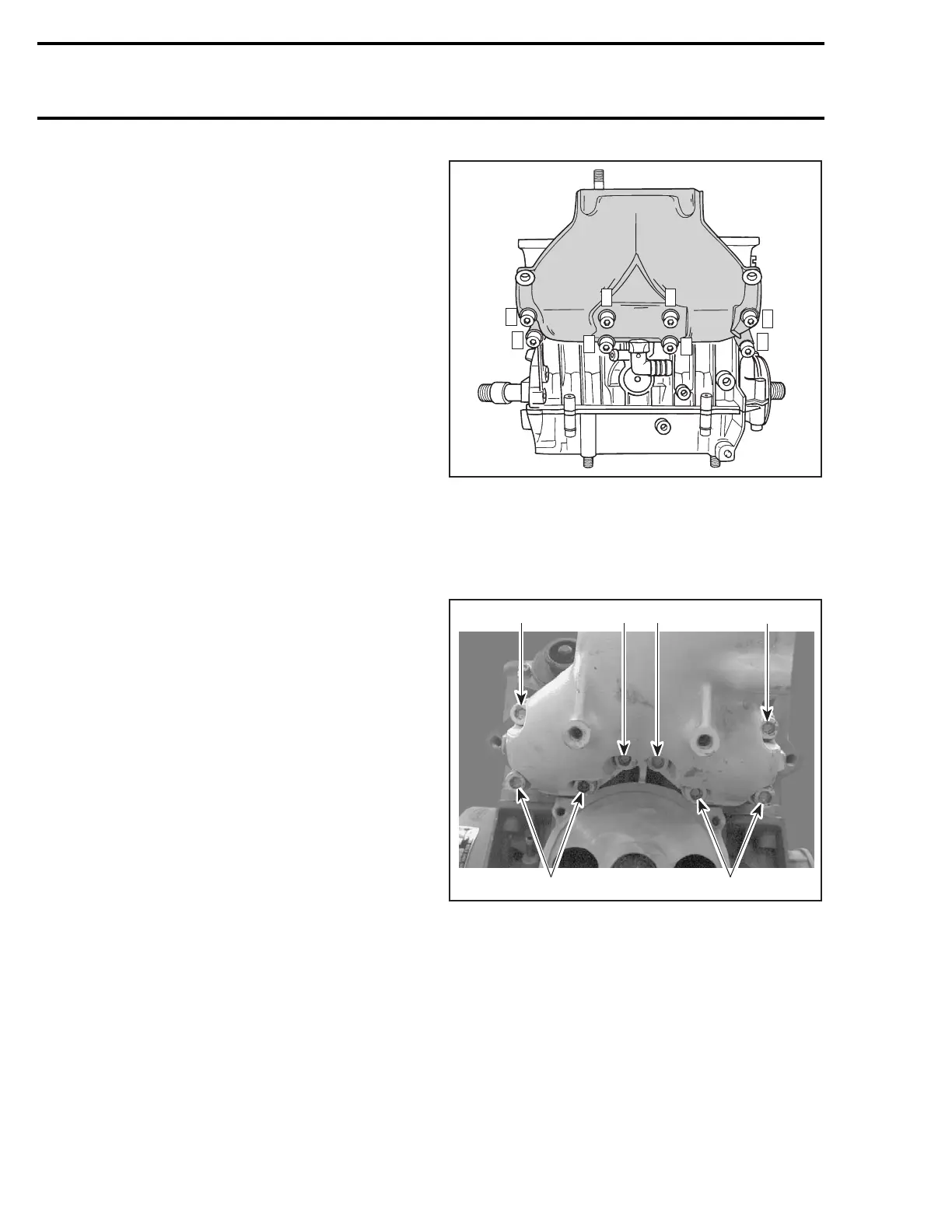

717 Engines

Apply Molykote 111 on threads of screws no. 12.

Install exhaust manifold no. 14 and torque screws

no. 12 to 24 N•m(17lbf•ft) as per following illus-

trated sequence.

F01D59A

1 3

5

8

2

4

7

6

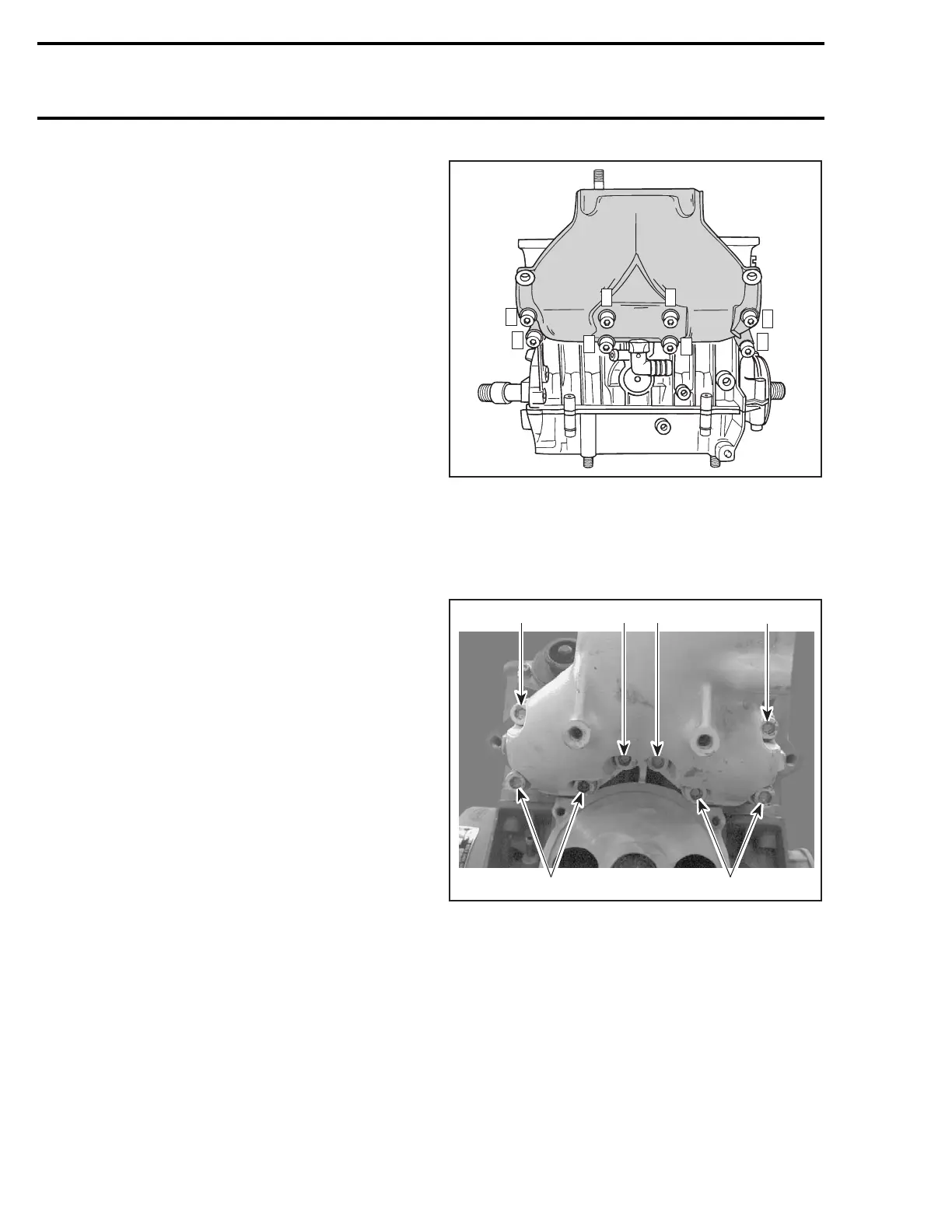

787 RFI Engines

Apply Loctite 518 on 2 screws no. 12. On the oth-

er screws no. 12, apply Molykote 111 on threads.

Install screws. Refer to the following illustration

for proper position of screws.

F01D82B

2

2

2

121

1. Screw with Loctite 518

2. Screw with Molykote 111

Torque exhaust manifold screws to 24 N•m

(17 lbf•ft) as per following illustrated sequence.

Repeat the procedure, retightening screws to

40 N•m(30lbf•ft).

174 smr2004-Complete Line Up

Loading...

Loading...