Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

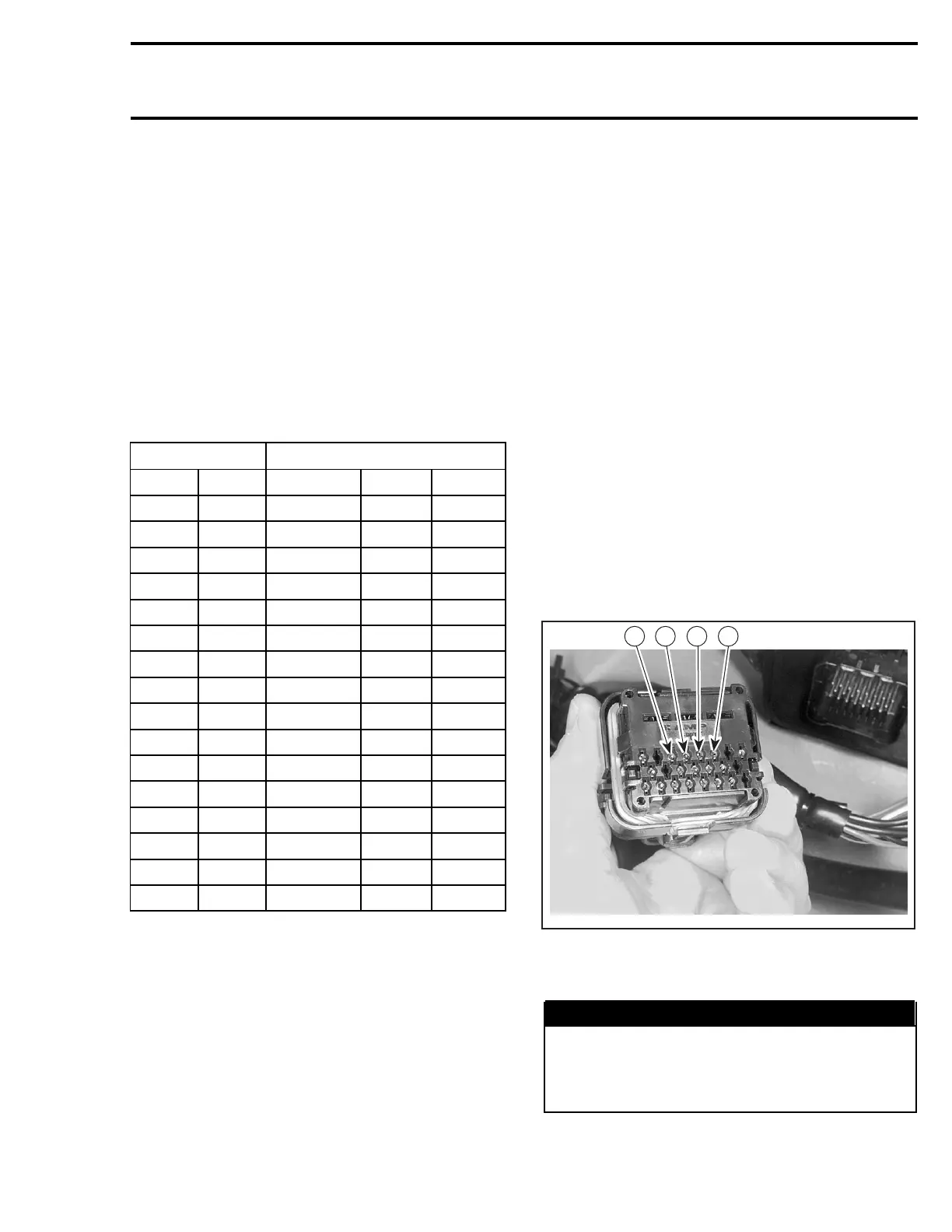

Resistance Measurement

When measuring the resistance with an ohmme-

ter, all values are given for a temperature of 20°C

(69°F). The value of a resistance varies with the

temperature. The resistance value for usual re-

sistor or windings (such as injectors) increases

as the temperature increases. However, our tem-

perature sensors are NTC types (Negative Tem-

perature Coefficient) and work the opposite which

means that the resistance value decreases as the

temperature increases. Take it into account when

measuring at temperatures different from 20°C

(69°F). Use this table for resistance variation rel-

ative to temperature for temperature sensors.

TEMPERATURE RESISTANCE (OHMS)

°C °F NOMINAL LOW HIGH

-30 -22 12600 11800 13400

-20

-4

11400 11000 11800

-10

14

9500 8000 11,000

0 32 5900 4900 6900

10 50 3800 3100 4500

20 68 2500 2200 2800

30 86 1700 1500 1900

40 104 1200 1080 1320

50 122 840 750 930

60 140 630 510 750

70 158 440 370 510

80 176 325 280 370

90 194 245 210 280

100 212 195 160 210

110 230

145

125 160

120 248 115 100 125

CONVERSION CHART FOR TEMPERATURE SENSORS

The resista

nce value of a temperature sensor may

test goo

d at a certain temperature but it might be

defec

tive at other temperatures. If in doubt, try a

ne

wsensor.

Also remember this validates the operation of the

sensor at ambient temperature. It does not val-

idate the over temperature functionality. To test

it, the sensor could be removed from the engine/

muffler and heated with a heat gun while it is still

connected to the harness to see if the MPEM will

detect the high temperature condition and gener-

ate a fault code.

When working with injectors, the resistance value

might test good while the complete current would

not flow through the wire when pulsating current

is supplied to the injector in its normal operation.

A solution would be to use a jumper wire to direct-

ly supply the injector from the MPEM. If it now

works, replace the defective wire. A Noid light

(available from after-market tool/equipment sup-

pliers) may also be used to validate the injector

operation.

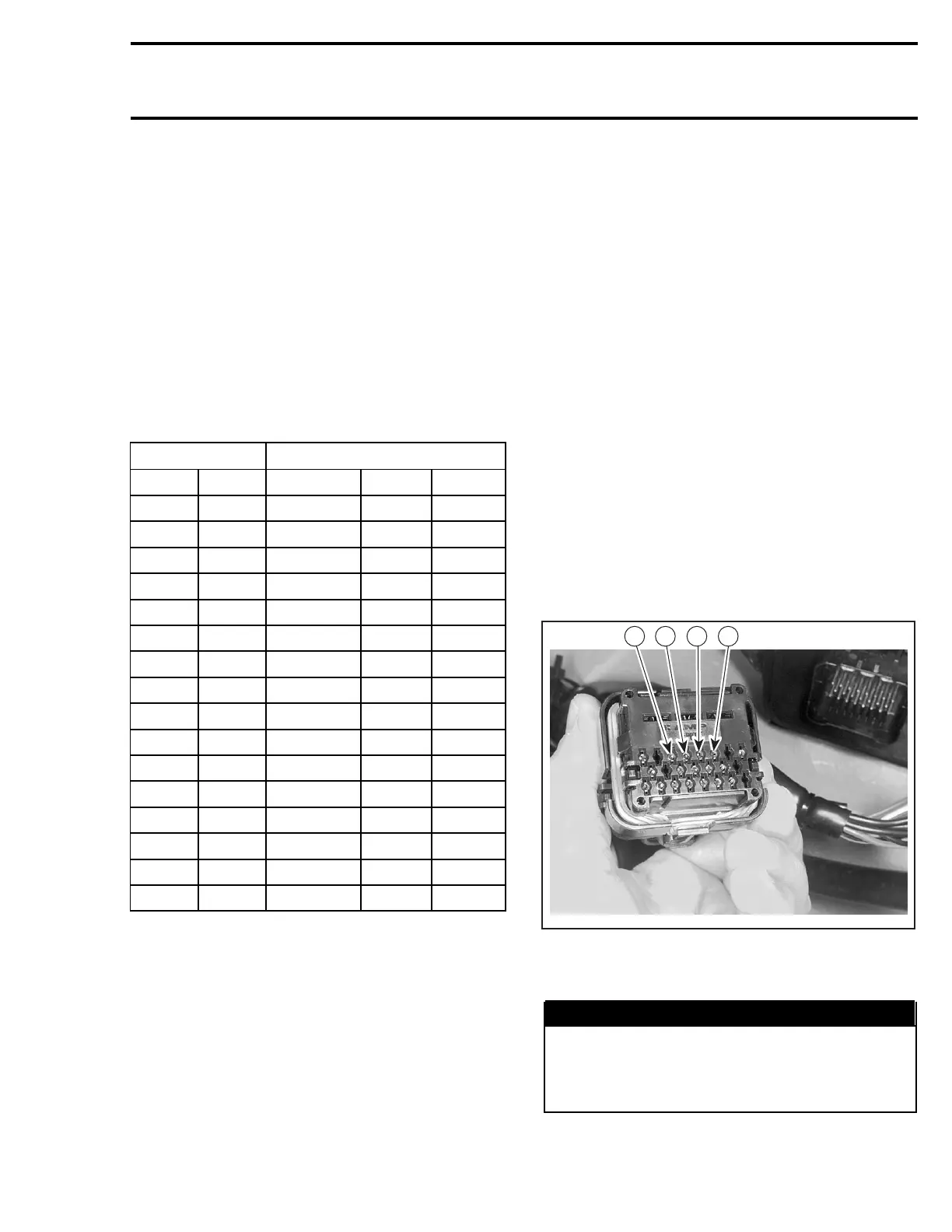

AMP CONNECTOR PIN-OUT

Use this diagram to locate the terminal numbers

on the AMP connector no. 3 and no. 4 of the

wiring harness when performing tests.

F07F15A

18 19 20 21

AMP CONNECTOR PIN-OUT (WIRING HARNESS SIDE)

QUICK FUEL PRESSURE TEST

WARNING

Read PRESSURE TEST under AIR/FUEL RAIL

further in this section for precautions and set-

up to take care of, before performing this test.

The procedure here is a quick summary.

smr2004-Complete Line Up 337

Loading...

Loading...