Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

After performing the required resets, ensure to

clear all faults from the newly replaced MPEM.

Now, all faults must be inactive (except the Diag-

nostic Cap Missing fault).

Start the engine and increase engine speed above

5000RPMtobesurenofaultappears.

THROTTLE POSITION SENSOR

(TPS)

General

The throttle position sensor (TPS) is a potentiome-

ter that sends a signal to the MPEM which is pro-

portional to the throttle shaft angle. On the DI sys-

tem, two sensors are used for redundancy purpos-

es. The MPEM compares the signals from both

sensors and determines if there is an error and

uses the most appropriate sensor to operate the

system.

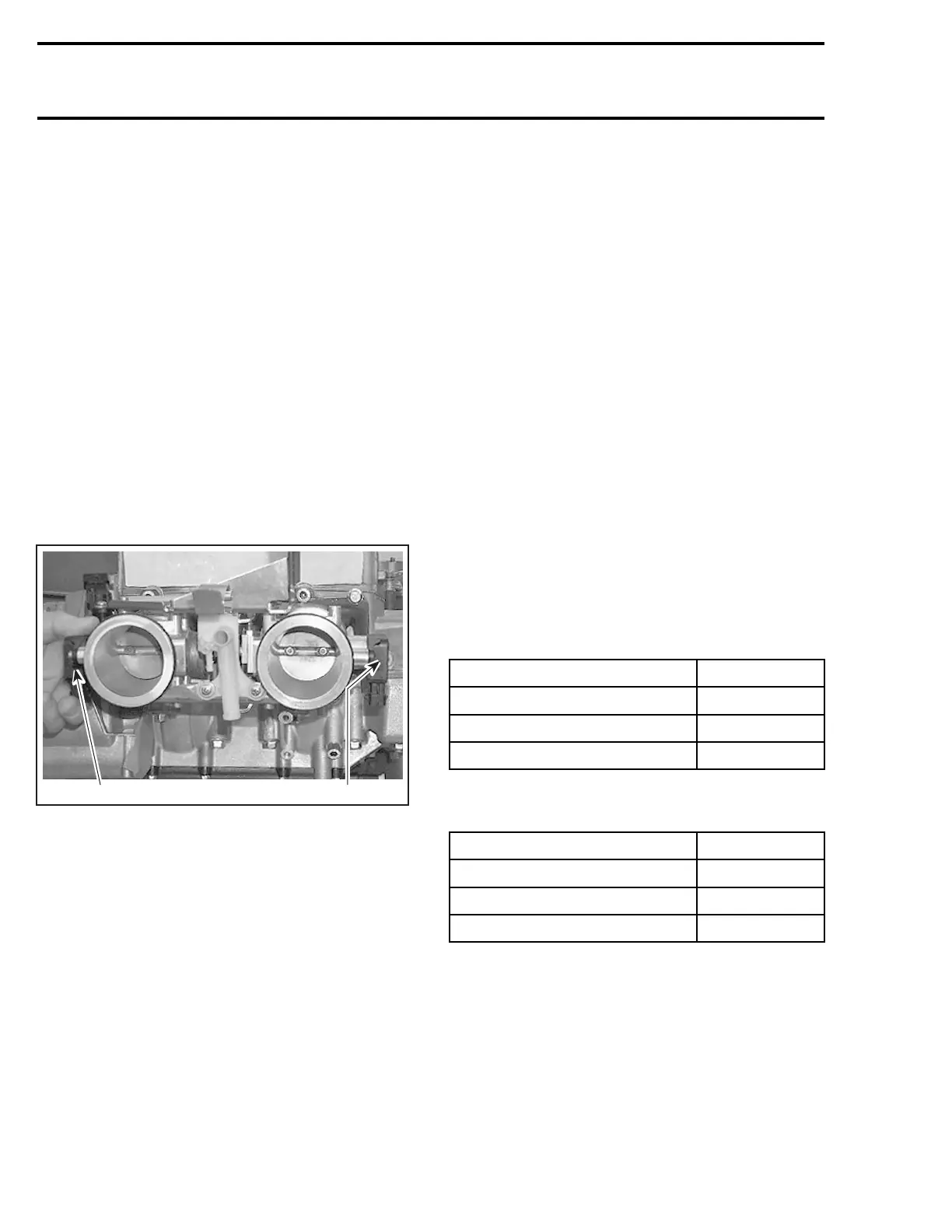

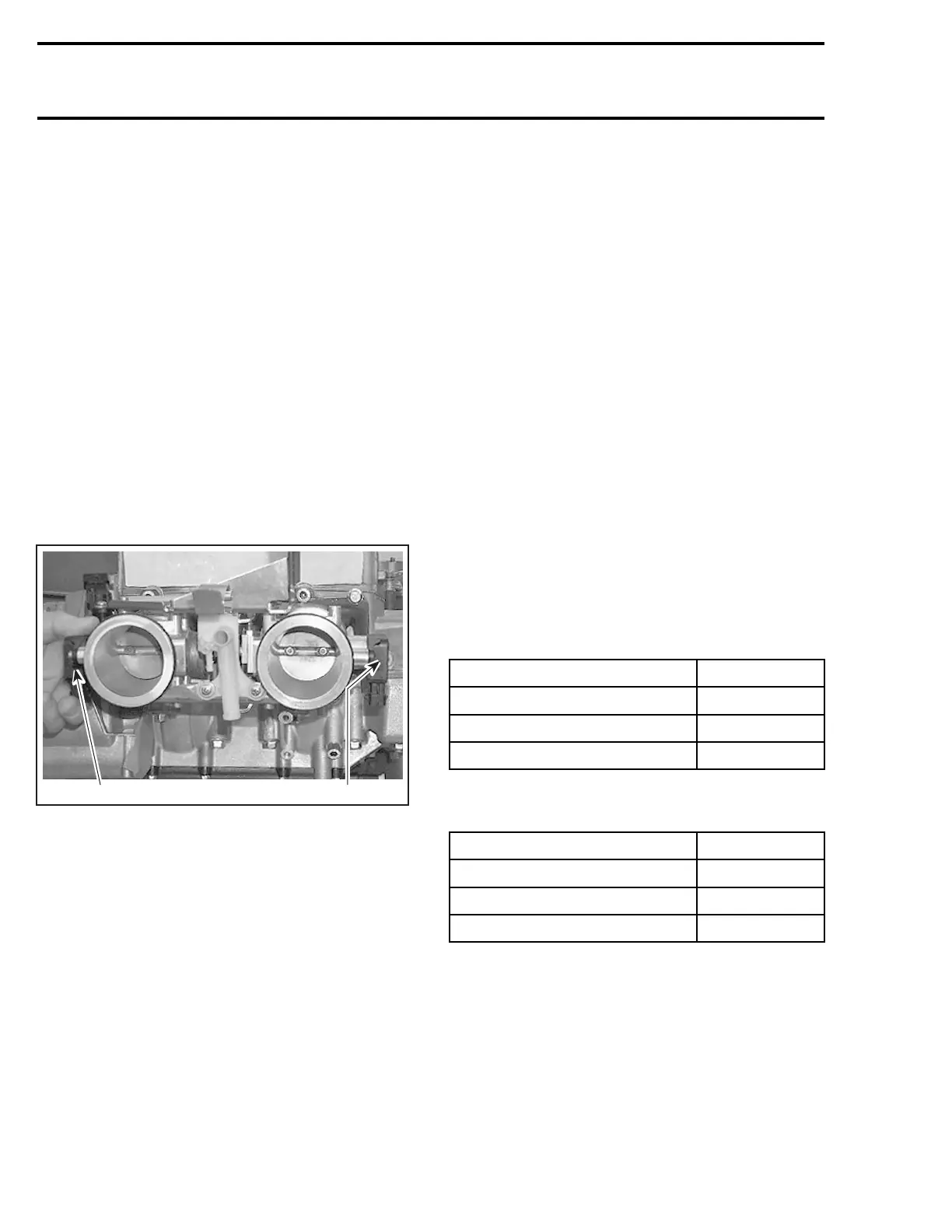

1

F12F05A

1

1. Throttle position sensor (TPS)

IMPORTANT: Prior to testing the TPS, ensure

that mechanical components/adjustments are

adequate according to THROTTLE BODY in AIR

INDUCTION SYSTEM above.

The MPEM may generate two types of fault codes

pertaining to the TPS. Refer to DI SYSTEM FAULT

CODES in DIAGNOSTIC PROCEDURES section

for more information.

Wear Test

While engine is not running, activate throttle and

pay attention for smooth operation without physi-

cal stops of the cable.

Using the vehicle communication kit (VCK) with

the B.U.D.S. software, use the Throttle Opening

display under Monitoring.

Slowly and regularly depress the throttle. Ob-

serve the needle movement. It must change

gradually and regularly as you move the throttle.

If the needle “sticks”, bounces, suddenly drops

or if any discrepancy between the throttle move-

ment and the needle movement is noticed, it

indicates a worn TPS that needs to be replaced.

NOTE: In this particular case, by comparing the

signals from both sensors, the MPEM will gener-

ate a fault code when the TPS is malfunctioning

due to specific “spots”.

To isolate the faulty TPS, disconnect one and test

the other.

Voltage Test — Both TPS

Check the MPEM voltage output on the desired

throttle position sensor.

Disconnect connector from throttle position sen-

sor and connect a voltmeter to the wiring harness.

Check the voltage readings on the PTO side as

follows.

CONNECTION VOLTAGE

Terminal 1 with engine ground 5V

Terminal 2 with engine ground 0V

Terminal 3 with engine ground 0-0.5V

Check the voltage readings on the MAG side as

follows.

CONNECTION VOLTAGE

Terminal 1 with engine ground 5V

Terminal 2 with engine ground 0V

Terminal 3 with engine ground 4.75 - 5 V

If voltage test is good, replace the TPS.

If voltage test is not good, check the resistance of

the TPS circuit.

Resistance Test

Reconnect the TPS.

358 smr2004-Complete Line Up

Loading...

Loading...