Section02MAINTENANCE

Subsection 01 (PERIODIC INSPECTION CHART)

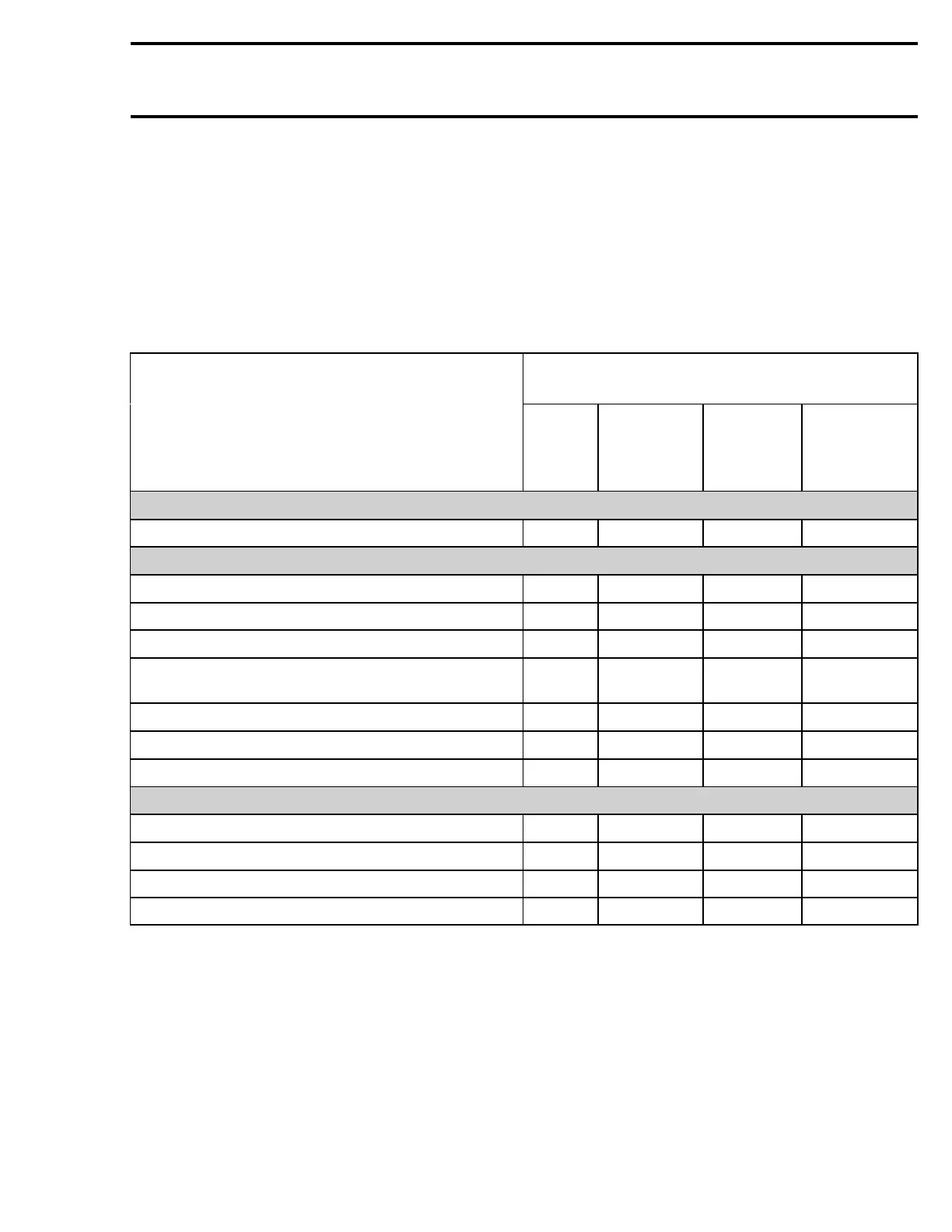

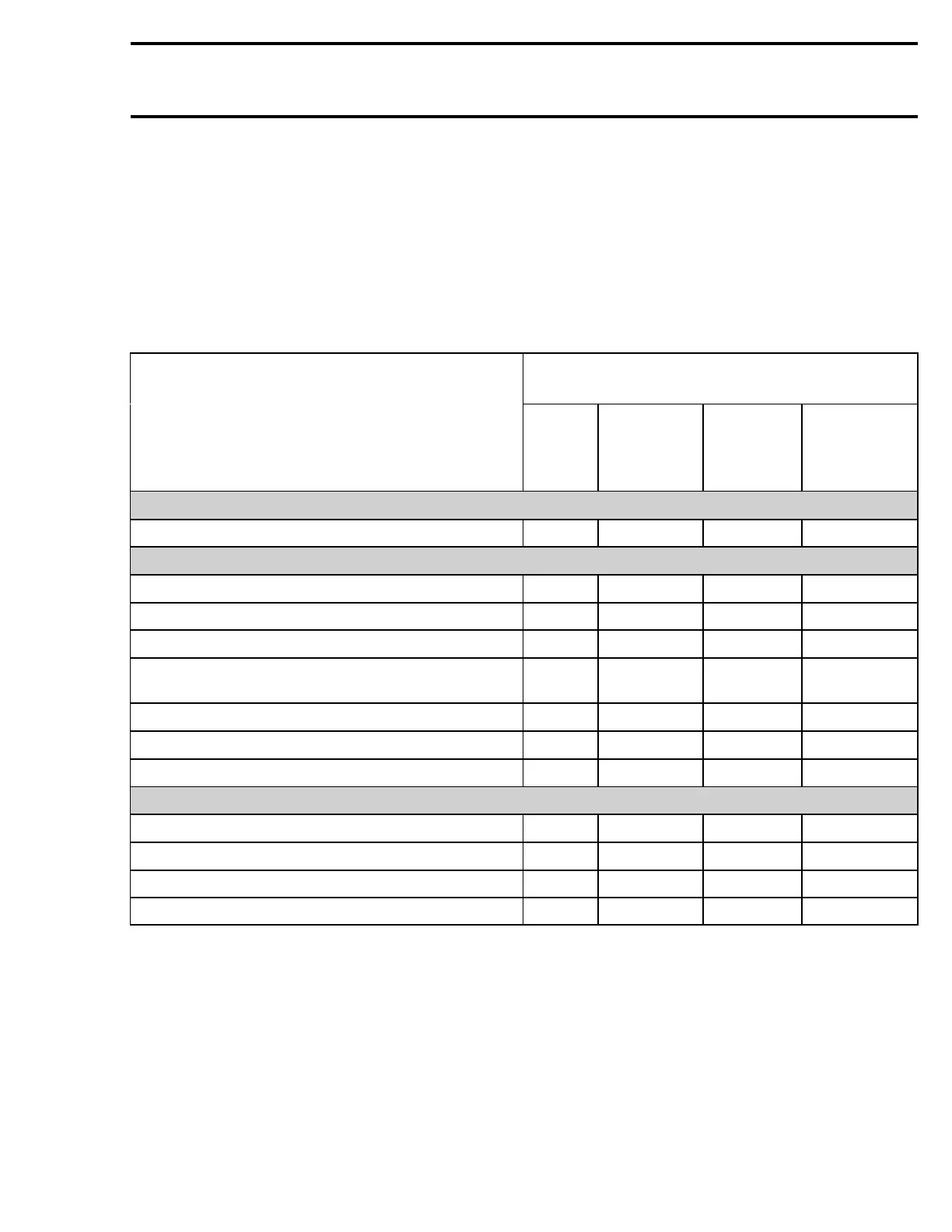

PERIODIC INSPECTION CHART

The schedule should be adjusted according to operating conditions and use.

NOTE: The chart gives an equivalence between number of hours and months/year. Perform the mainte-

nance operation to whatever time comes first.

IMPORTANT: Schedule for watercraft rental operations or higher number of hour use, will require greater

frequency of inspection and maintenance.

2-Stroke Models

DESCRIPTION

INTERVAL

I

: Inspect, verify, clean, adjust, lubricate.

Replace if necessary

C

:Clean

L

: Lubricate

R

: Replace

FIRST

10

HOURS

EVERY

25 HOURS

OR

3MONTHS

EVERY

50 HOURS

OR

6MONTHS

EVERY

100 HOURS

OR

1YEAR

GENERAL

Lubrication/corrosion protection (1) L

ENGINE

Support and rubber mount I I

Exhaust system fasteners (5) I I

RAVE valve (if so equipped) (5)

C C

Top end (leak test, piston and ring clearance)

(DI models only) (5)

(9)

Counterbalance shaft oil level (if so equipped)

I I

Spark plug

I(4) R

Ignition timing (5) I(9)

COOLING SYSTEM

Flushing

C(3)

Hose and fasteners I I

Engine drain tubes I(1)

Water flow regulator valve (if so equipped) I

smr2004-Complete Line Up 21

Loading...

Loading...