Section 07 ENGINE MANAGEMENT (DI)

Subsection 02 (COMPONENT INSPECTION AND ADJUSTMENT)

Ensure the throttle body plate stop lever rests

against its stopper. Open throttle approximately

one quarter then quickly release. Repeat 2 - 3

times to settle throttle plate. If stopper does not

rest against its stop lever, perform throttle cable

adjustment. Refer to THROTTLE BODY in AIR IN-

DUCTION SYSTEM above.

Push the Reset button in the Setting tab of

B.U.D.S.

NOTE: There is no idle speed adjustment to per-

form. The MPEM takes care of that. If TPS are

not within the allowed range while resetting the

closed TPS, the MPEM will generate a fault code

and will not accept the setting. To solve that, per-

form the Validating TPS Synchronization in the

MPEM REPLACEMENT section above.

Start engine and make sure it operates normally

through its full engine RPM range. If fault codes

appear, refer to DI SYSTEM FAULT CODES in DI-

AGNOSTIC PROCEDURES section for more infor-

mation.

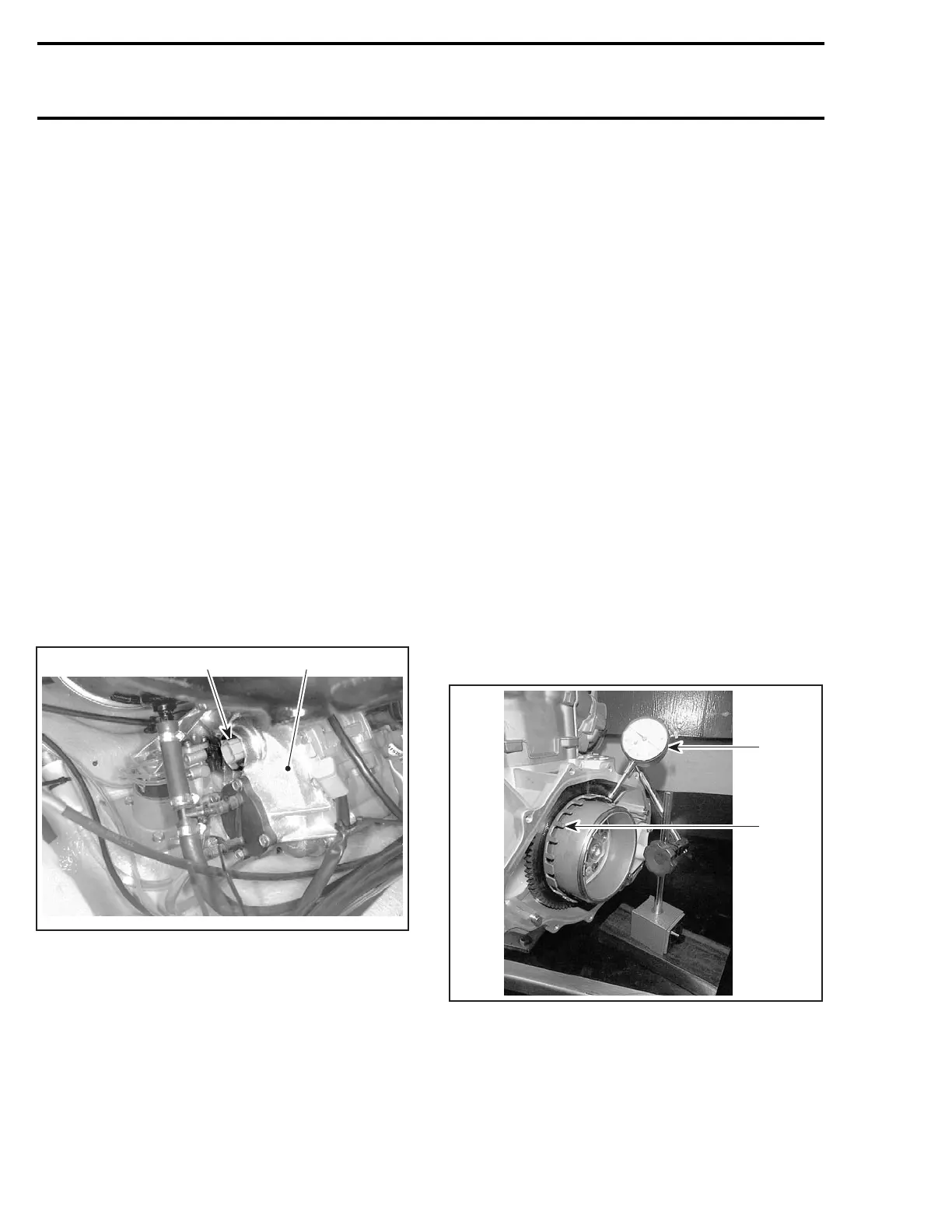

CRANKSHAFT POSITION

SENSOR (CPS)

2

F12R0OA

1

1. Magneto cover

2. CPS connector

Check for RPM display at the information center

while cranking engine (first ensure information

center is in tachometer mode). If i

tdisplaysap-

proximately 300 RPM, the CPS cir

cuitry is proper-

ly working.

Otherwise, validate the information center is

working by activating the tachometer using the

software B.U.D.S. under Activation (first ensure

information center is in tachometer mode). If

it does not display 3000 RPM, the information

center may be faulty and needs to be tested.

If the information center correctly displayed

3000 RPM, perform the following tests.

Take into account that a CPS fault can be trig-

gered by bent or missing encoder wheel teeth.

Check the teeth condition. Also, bad connections

in magneto connector could generate electrical

noise that would make you wrongly think the CPS

is faulty. Check terminals and wires.

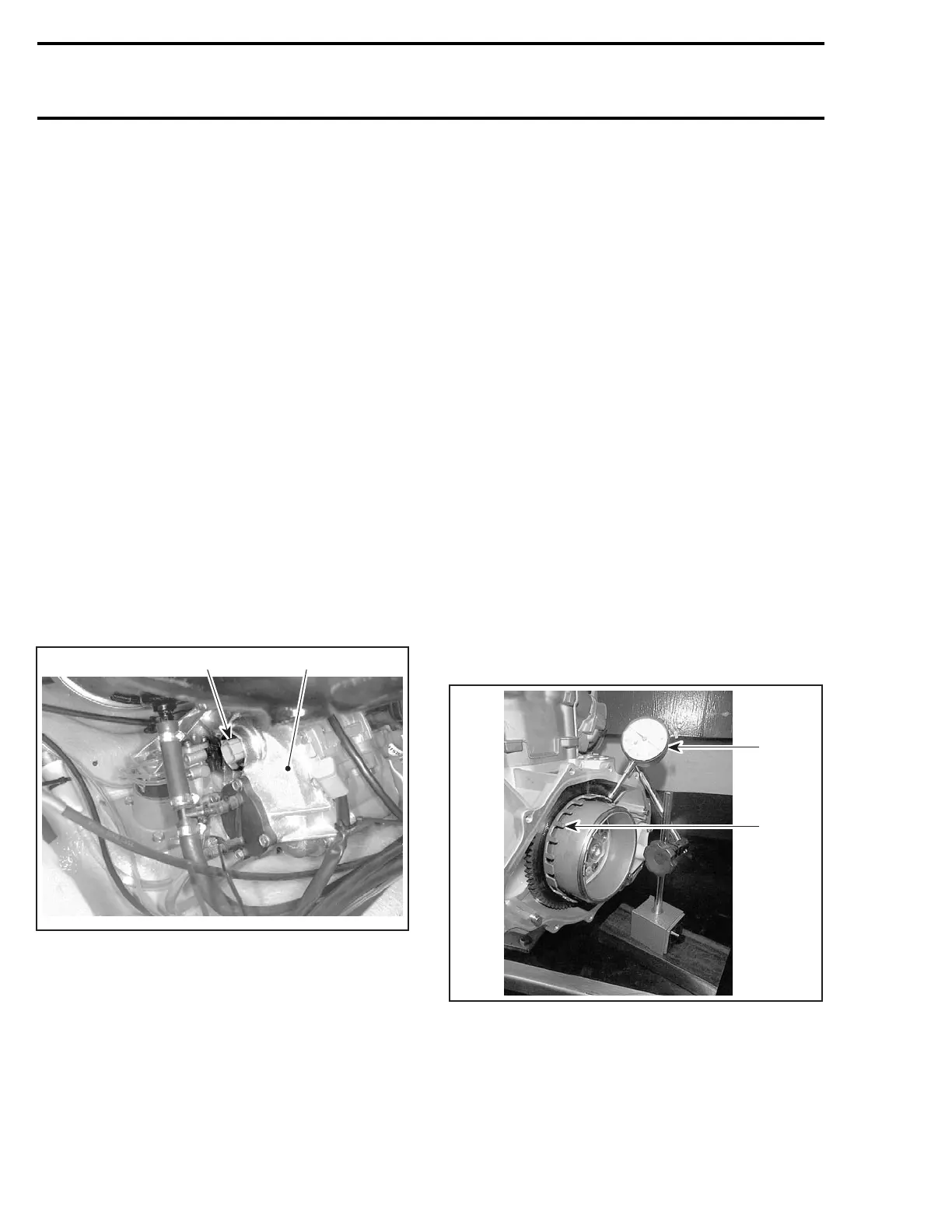

Encoder Wheel Inspection

To check the encoder wheel for bent teeth, pro-

ceed as follows.

Remove magneto cover. Refer to MAGNETO

SYSTEM in ENGINE section.

Install a dial indicator on crankcase. Position

the gauge on a tooth and set it to zero (0). Ro-

tate flywheel and check needle movement. The

maximum allowed difference between teeth is

0.15 mm (.006 in). Otherwise, straighten the

tooth or replace the encoder wheel.

F12R1HA

2

1

1. Encoder wheel

2. Dial indicator

Properly reinstall cover.

360 smr2004-Complete Line Up

Loading...

Loading...