Section 04 ENGINE (2-STROKE)

Subsection 04 (TOP END)

947 DI Engines

Due to the semi-trapez rings, it is not possible to

accurately measure ring/piston groove clearance.

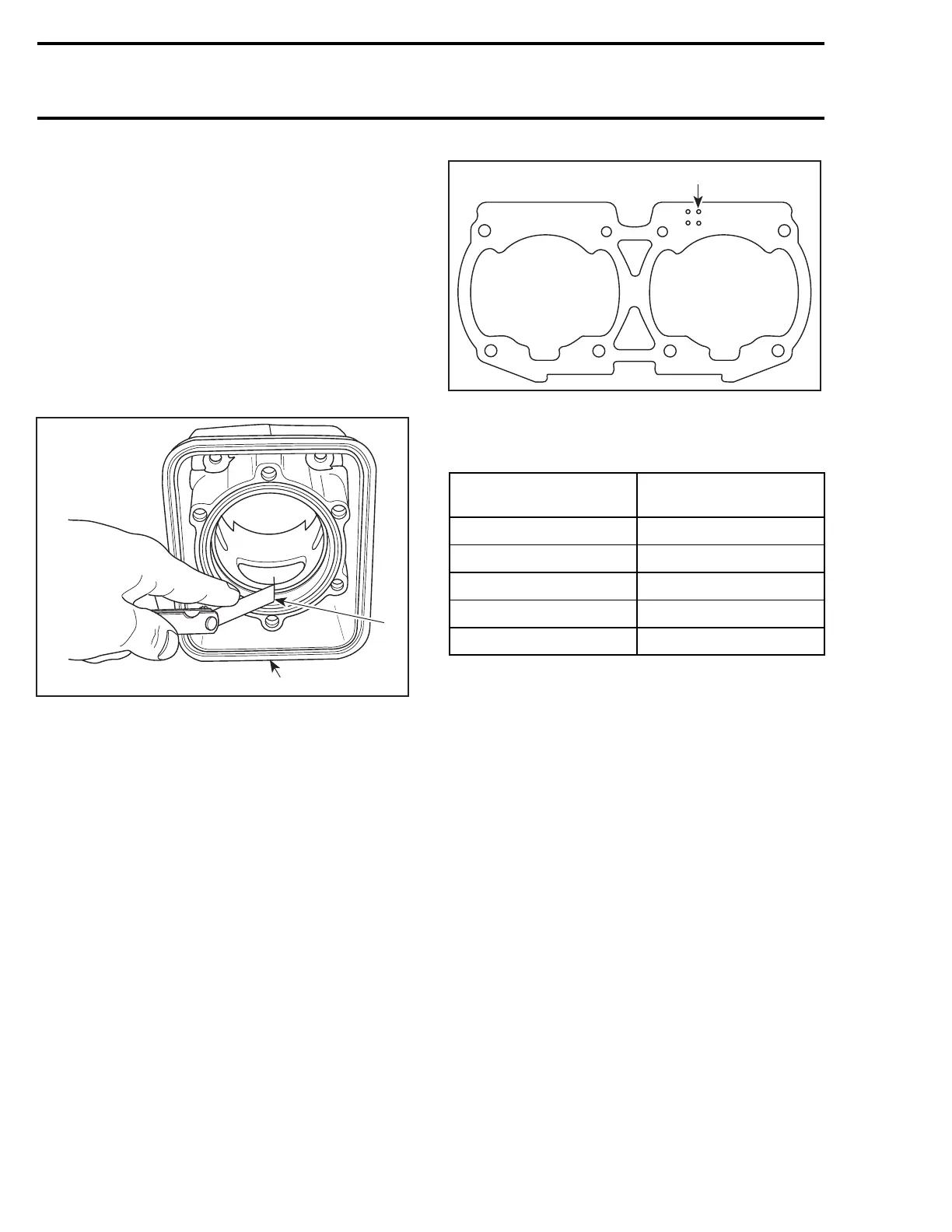

Ring End Gap

Position ring halfway between exhaust port and

top of cylinder.

NOTE: In order to correctly position ring in cylin-

der, use piston as a pusher.

Using a feeler gauge, check ring end gap. If gap

exceeds specified tolerance, rings should be re-

placed.

F01D0OA

1

2

1. Top of cylinder

2. Ring end gap

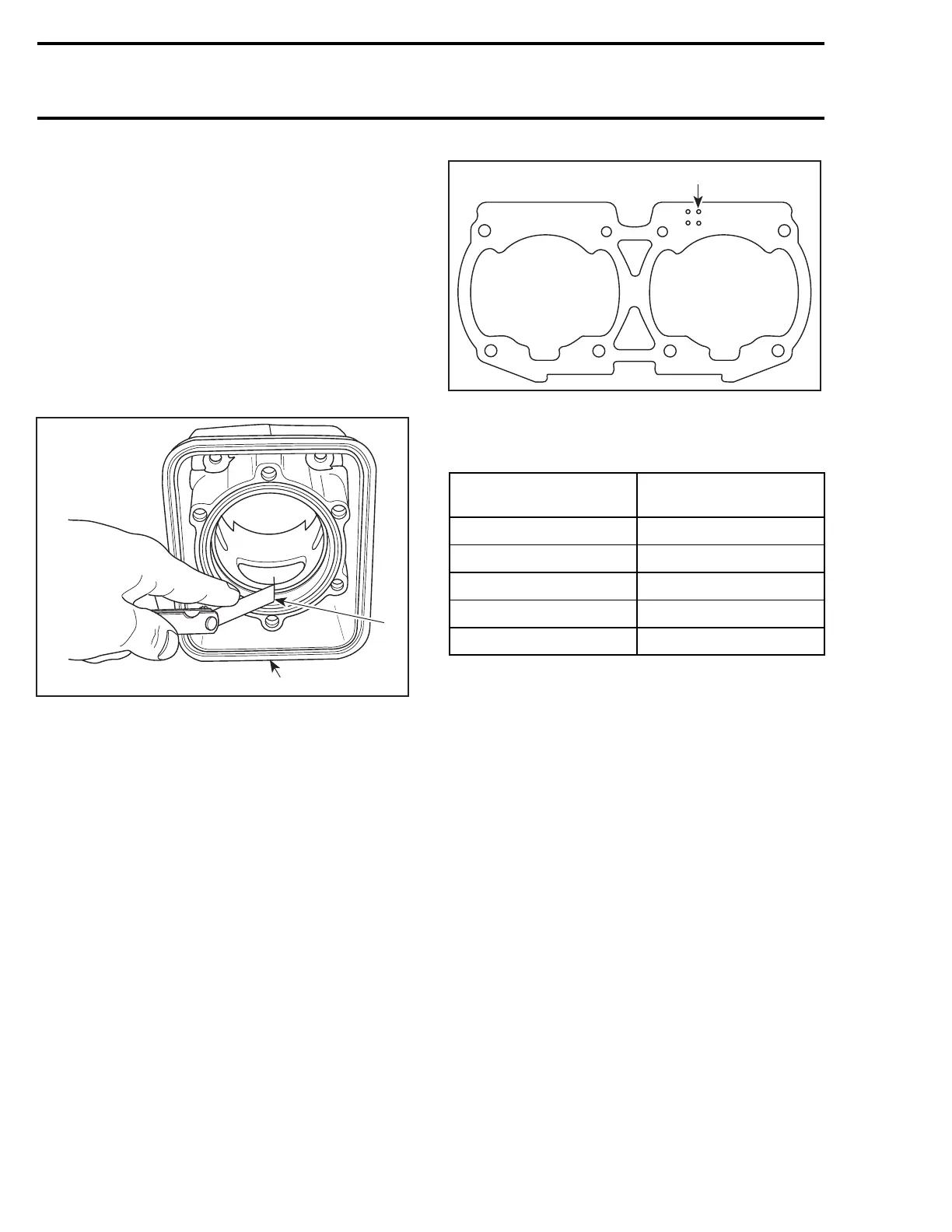

Cylinder Base Gasket

NOTE: The general procedure is to install a new

gasket of the same thickness. However, if you

do not know the gasket thickness that was in-

stalled or if a crank repair has involved replace-

ment of connecting rods, refer to the COMBUS-

TION CHAMBER VOLUME MEASUREMENT to

properly determine the required gasket thickness.

Different thicknesses of cylinder base gaskets are

used for a precise adjustment of the combustion

chamber volume.

To identify gasket thickness, refer to the identifi-

cation holes on the gasket.

F01D67A

1

TYPICAL

1. Identification holes

All Engines

GASKET THICKNESS

IDENTIFICATION

HOLES

0.3 mm (.012 in) 3

0.4 mm (.016 in) 4

0.5 mm (.020 in)

5

0.6 mm (.024 in) 6

0.8 mm (.031 in) 8

RAVE Valve

787 RFI and 947 DI Engines

Check RAVE valve bellows no. 21 for cracks.

ASSEMBLY

Assembly is essentially the reverse of disassem-

bly procedures. However pay particular attention

to the following.

RAVE Valve

787 RFI Engines

Make sure to insert O-ring no. 23 onto rod of slid-

ing valve no. 22.

The TOP position of the sliding valve no. 22 is

indicated on one side.

116 smr2004-Complete Line Up

Loading...

Loading...