INTRODUCTION

– Apply Loctite Primer N (P/N 293 800 041) on

threads and allow to dry.

– Put several drops of proper strength Loctite

threadlocker on female threads and in hole.

– Apply several drops of proper strength Loctite

on stud threads.

– Install stud.

– Install cover, etc.

– Apply drops of proper strength Loctite on un-

covered threads.

– Tighten nuts as required.

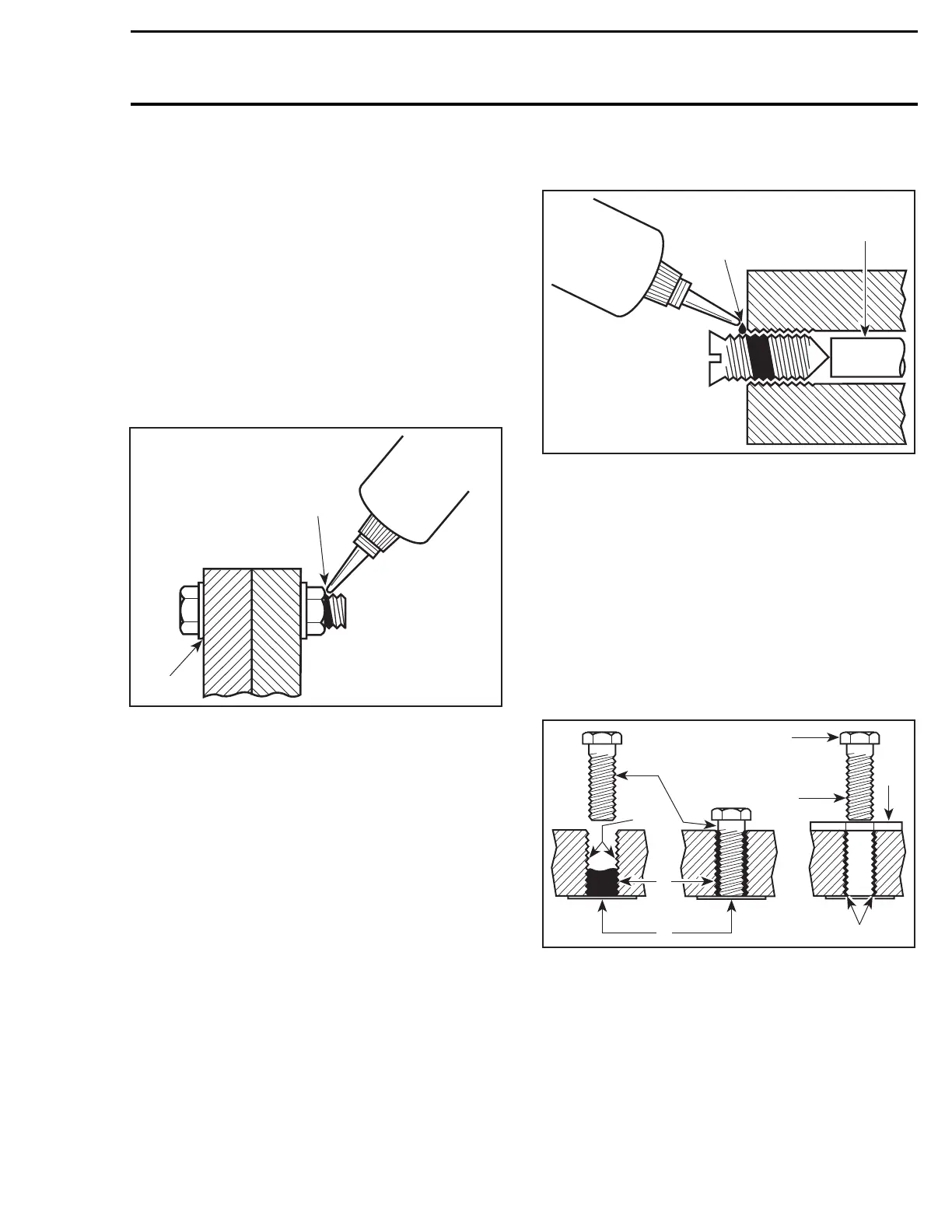

Preassembled Parts

A00A3OA

1

2

1. Apply here

2. Do not apply

– Clean bolts and nuts with solvent.

– Assemble components.

– Tighten nuts.

– Apply drops of proper strength Loctite on

bolt/nut contact surfaces.

– Avoid touching metal with tip of flask.

NOTE: for preventive maintenance on exist-

ing equipment, retighten nuts and apply proper

strength Loctite on bolt/nut contact surfaces.

Adjusting Screw

A00A3PA

1

2

1. Apply here

2. Plunger

– Adjust screw to proper setting.

– Apply drops of proper strength Loctite thread-

locker on screw/body contact surfaces.

– Avoid touching metal with tip of flask.

NOTE: if it is difficult to readjust, heat screw with

a soldering iron (232°C(450°F)).

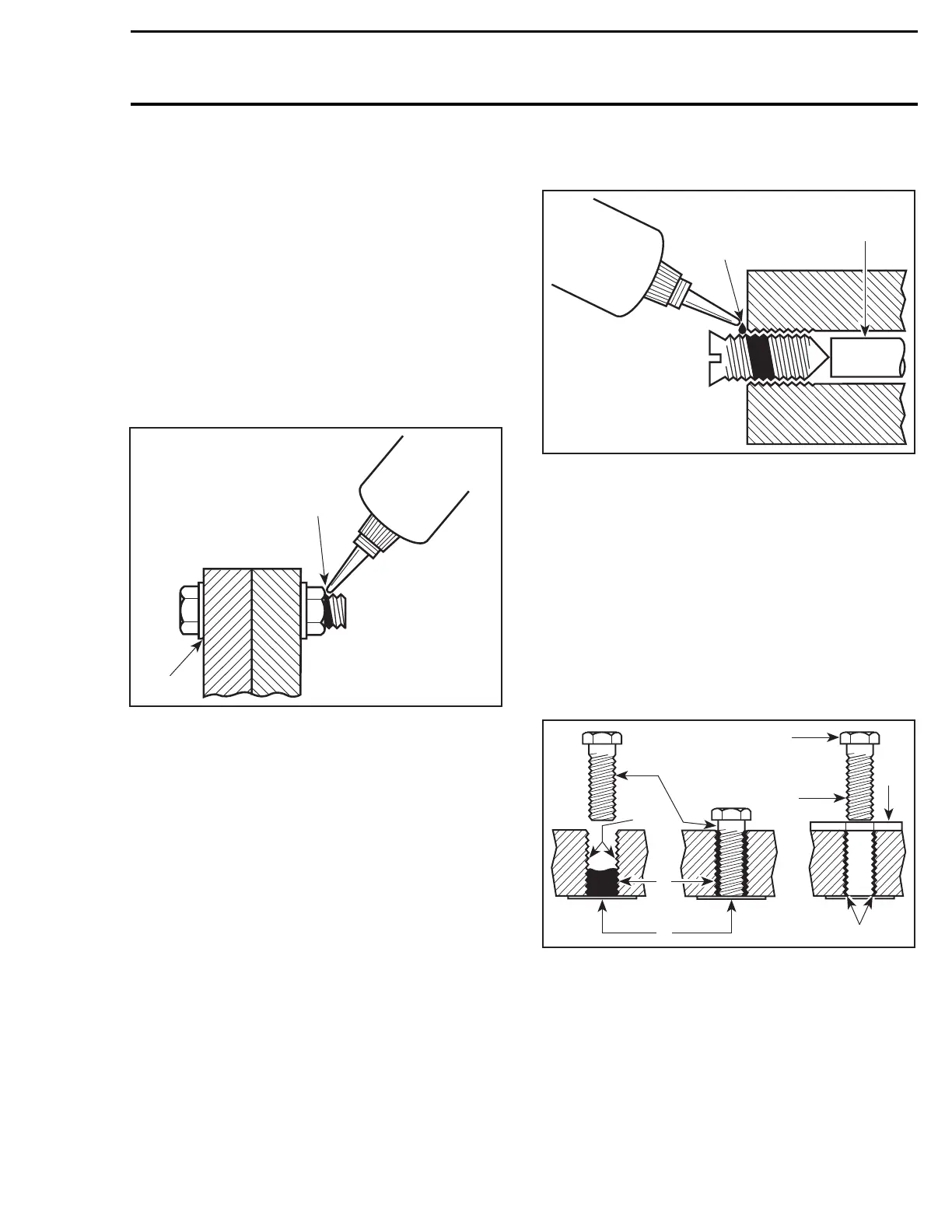

STRIPPED THREAD REPAIR

Stripped Threads

A00A3QA

5

8

6

7

1

2

3

4

1. Release agent

2. Stripped threads

3. Form-A-Thread

4. Tape

5. Cleaned bolt

6. Plate

7. New threads

8. Threadlocker

Standard Thread Repair

– Follow instructions on Loctite FORM-A-

THREAD 81668 package.

XXI

Loading...

Loading...