Section 08 ENGINE MANAGEMENT (4-TEC)

Subsection 01 (OVERVIEW)

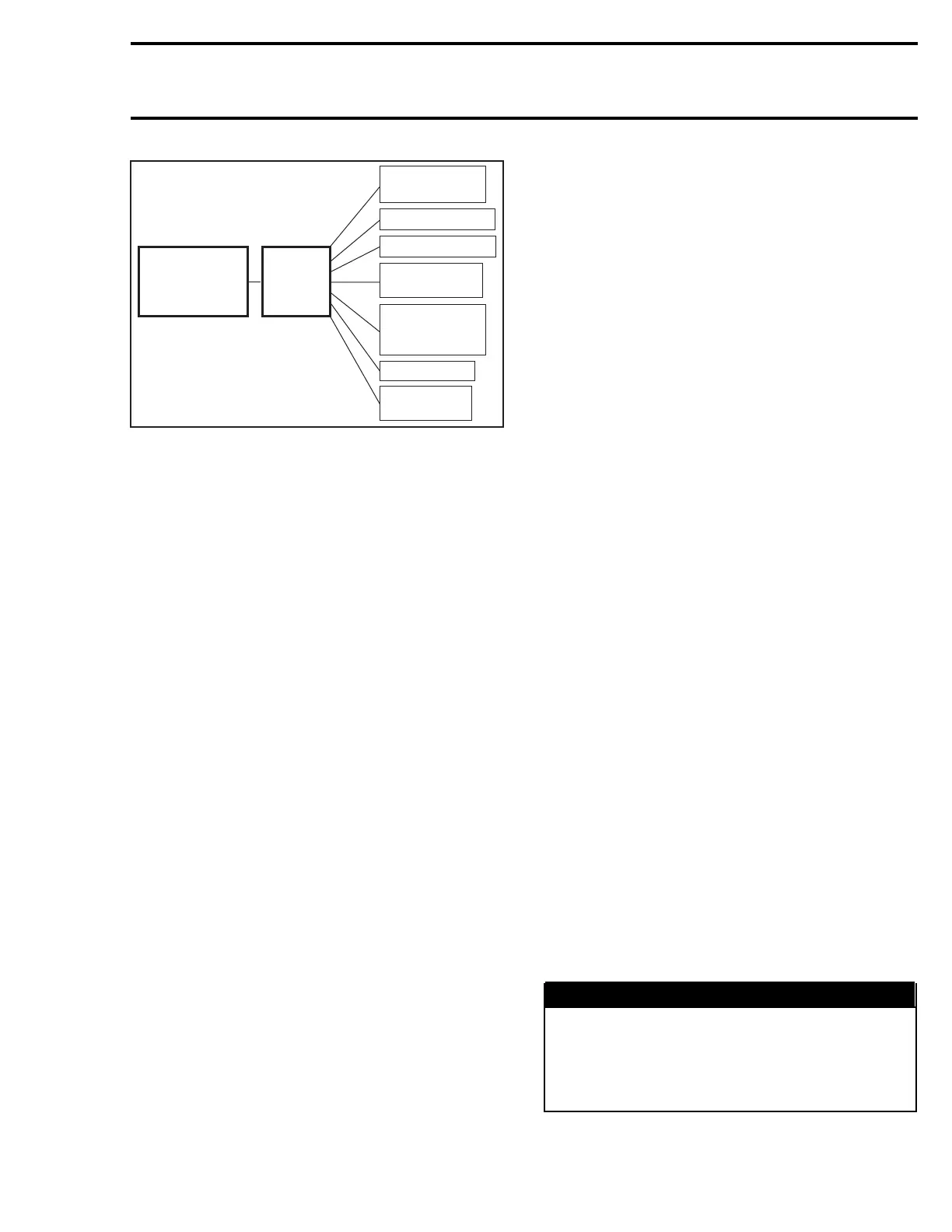

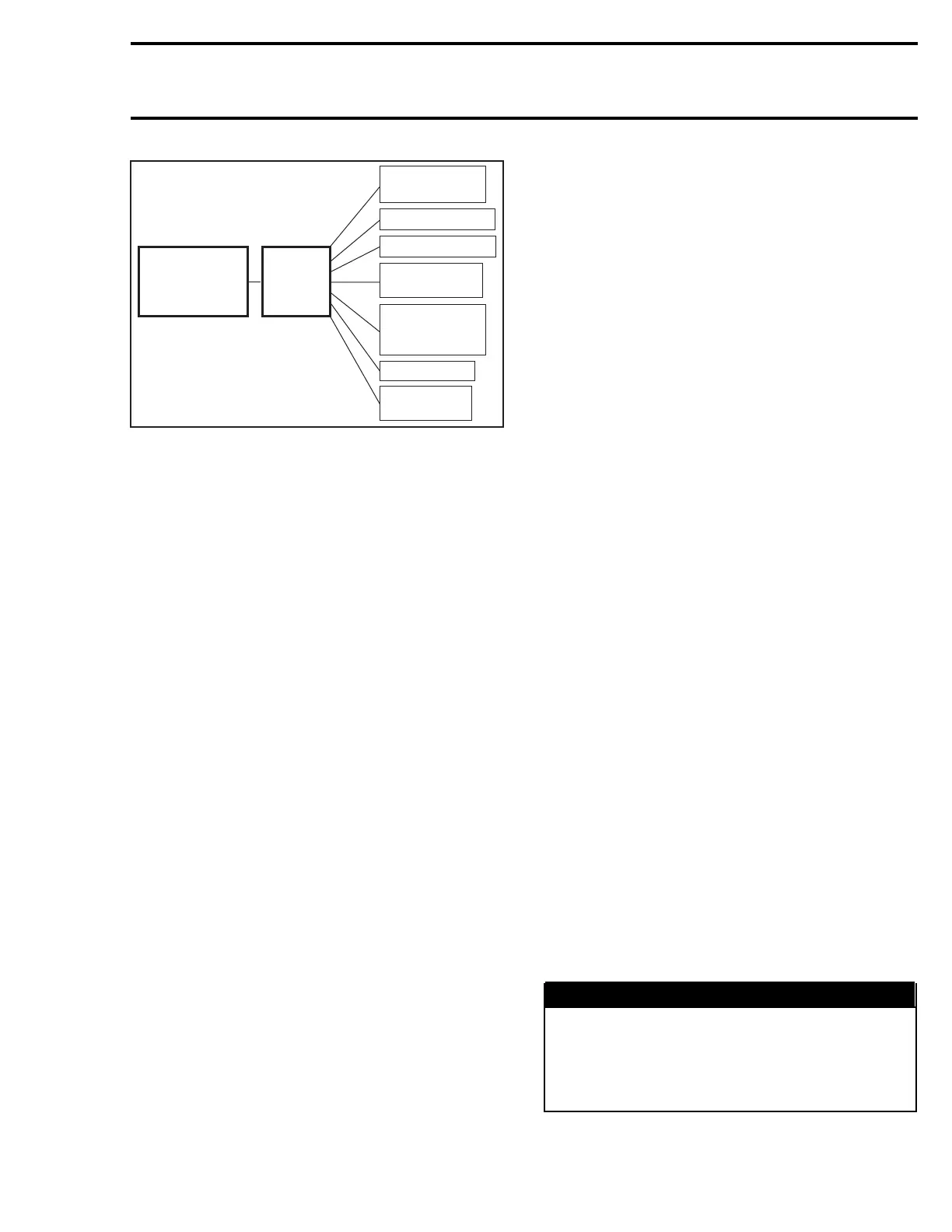

Fuel injection

system

Ignition system

Starting system

Data transfer

with VCM

DESS system

and learning

key

RPM limiter

Limp home

mode

Engine

Control

Module

(ECM)

R1503motr334A

Engine

Management

System

(EMS)

EMS FUNCTIONS

The ECM gets its power by the MPEM which is di-

rectly powered by the battery. It is responsible for

the following engine management/electrical func-

tions:

– interpreting information

– distributing information

– start/stop function

– DESS (Digitally Encoded Security System)

– ignition timing control

– injection control

– The ECM applies the proper map (injection and

ignition) for optimum engine operation in all con-

ditions.

– engine RPM limiter

– etc.

The ECM features a permanent memory that will

keep the programmed safety lanyard(s) active,

fault codes and other engine information, even

when the battery is removed from the watercraft.

EMS — GENERAL FUNCTIONS

Safety Lanyard Reminder

If engine is not started within 5 seconds after in-

stalling the safety lanyard on its post, 4 very short

beeps every 3 second interval will sound for ap-

proximately 4 hours to remind you to start the en-

gine or to remove safety lanyard. Afterwards, the

beeps will stop. The same will occur when safety

lanyard is left on its post 5 seconds after engine is

stopped.

Always ensure safety lanyard is not left on its post

after engine is stopped.

IMPORTANT: Leaving the safety lanyard on its

post when engine is not running will slowly dis-

charge the battery.

Antistart Feature

This system allows starting the vehicle only with

safety lanyard(s) that has been programmed to op-

erate a specific watercraft. This functionality is

the DESS system. See below for details.

Digitally Encoded Security

System (DESS)

The following components are specially designed

for this system: Multi-Purpose Electronic Module

(MPEM), ECM, safety lanyard cap and safety lan-

yard post.

The safety lanyard cap contains a magnet and a

ROM chip. The magnet actually closes the reed

switch inside the post which is the equivalent

of a mechanical ON/OFF switch. The chip has a

unique digital code.

The DESS circuitry in the ECM is activated at the

factory. Therefore, a safety lanyard must be pro-

grammed to start the engine.

When ordering a new ECM from the regular parts

channel, the DESS circuitry will be activated.

NOTE: Actually, it is the memory of the ECM

whichisprogrammedtorecognizethedigitalcode

of the safety lanyard cap. This is achieved with

the VCK (Vehicle Communication Kit) (P/N 529 035

981). Refer to B.U.D.S. help system to program

a safety lanyard.

The system is quite flexible. Up to 8 safety lan-

yards may be programmed in the memory of the

watercraft ECM. They can also be erased individ-

ually.

The ECM also offers a special safety lanyard — the

Sea-Doo LK™ (learning key) — which can be pro-

grammed so that the vehicle can be run only at a

limited speed — approximately 55 km/h (35 MPH).

Such feature is ideal for first time riders or renters.

WARNING

When programming a Sea-Doo LK™ (learn-

ing key), use only a lanyard that is identi-

fied for that purpose. Otherwise, a customer

could use a vehicle with a greater speed than

he was expecting.

smr2004-Complete Line Up 397

Loading...

Loading...