INTRODUCTION

TIGHTENING TORQUES

Tighten fasteners to torque mentioned in exploded views and/or text, When they are not specified, refer

to following table.

WARNING

Torque wrench tightening specifications must strictly be adhered to. Locking devices (ex.: lock-

ing tabs, elastic stop nuts, self-locking fasteners, etc.) must be installed or replaced with new

ones, where specified. If the efficiency of a locking device is impaired, it must be renewed.

In order to avoid a poor assembling, tighten screws, bolts or nuts in accordance with the following pro-

cedure:

– Manually screw all screws, bolts and/or nuts.

– Apply the half of the recommended torque value.

CAUTION: Be sure to use the proper tightening torque for the proper strength grade.

NOTE: When possible, always apply torque on the nut.

– Torque to the recommended torque value.

NOTE: Always torque screws, bolts and/or nuts in a criss-cross sequence.

A00A8BS

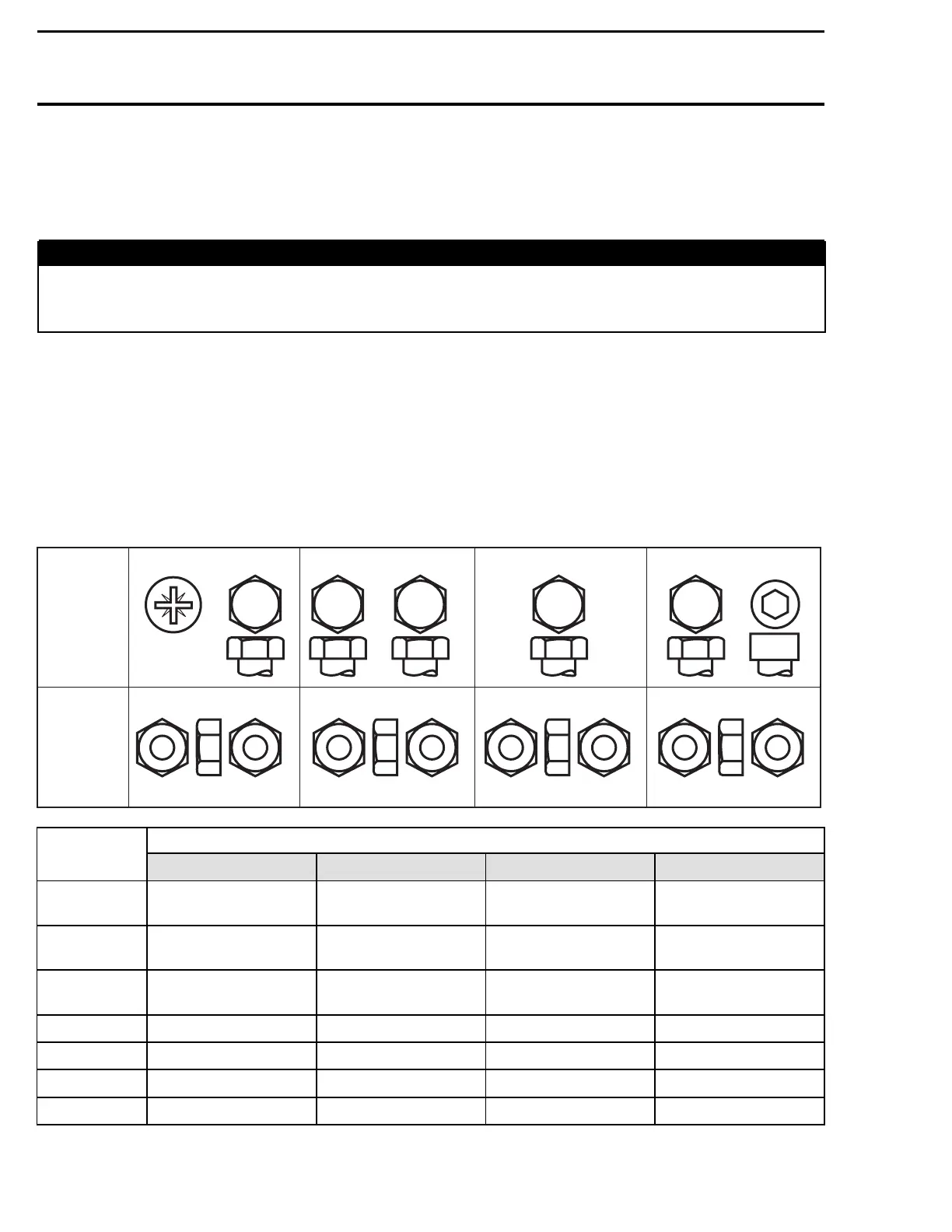

Property

class

and

head

markings

Property

class

and

nut

markings

5

5

10

10

10

10

12

12

4.8

4.8

4.8

8.8

8.8

8.8

9.8

9.8

9.8

10.9

10.9

10.9

12.9

12.9

12.9

12.9

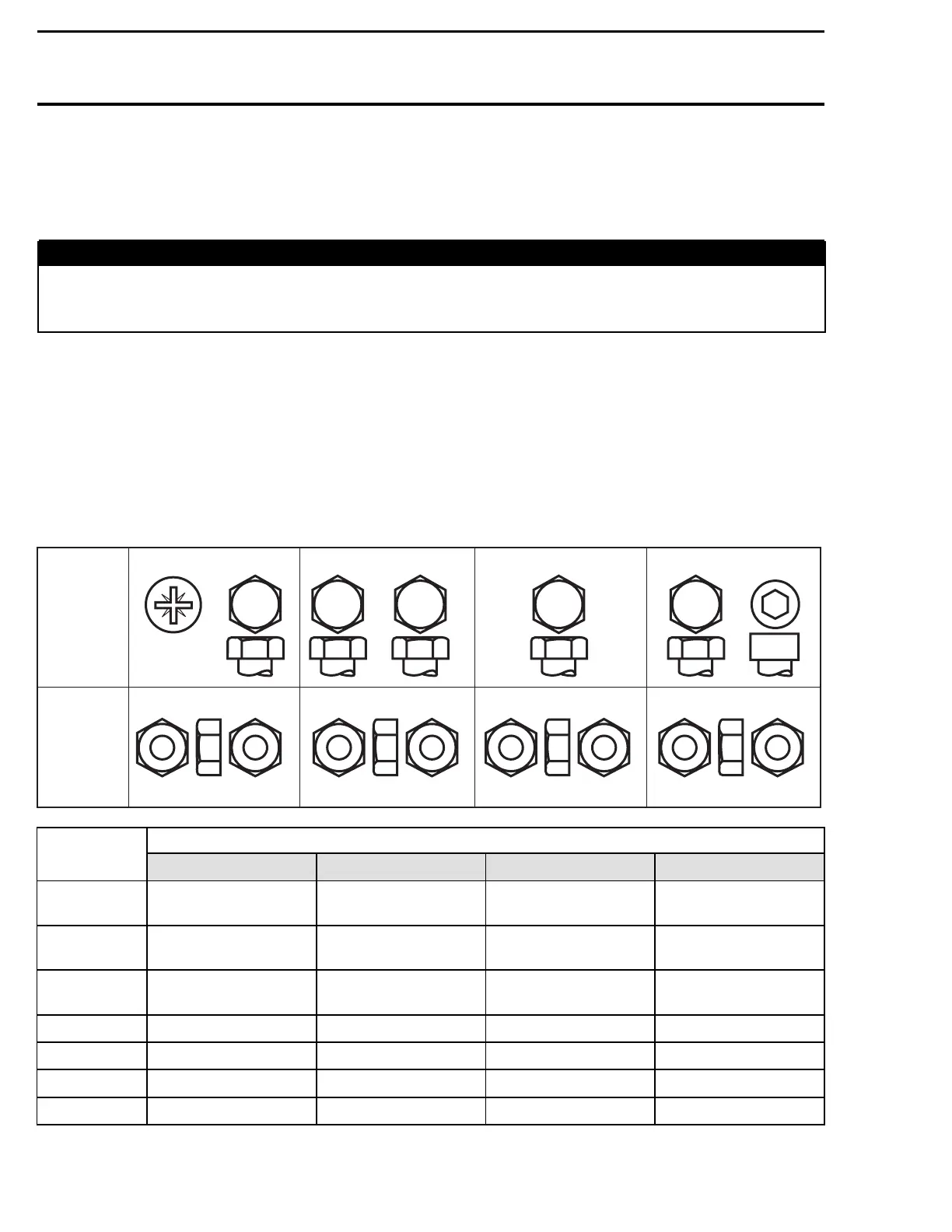

FASTENER GRADE/TORQUE

FASTENER

SIZE

5.8

Grade

8.8

Grade

10.9

Grade

12.9

Grade

M4

1.5 — 2N•m

(13 — 18 lbf•in)

2.5 — 3N•m

(22 — 27 lbf•in)

3.5 — 4N•m

(31 — 35 lbf•in)

4 — 5N•m

(35 — 44 lbf•in)

M5

3 — 3.5 N•m

(27 — 31 lbf•in)

4.5 — 5.5 N•m

(40 — 47 lbf•in)

7 — 8.5 N•m

(62 — 75 lbf•in)

8 — 10 N•m

(71 — 89 lbf•in)

M6

6.5 — 8.5 N•m

(58 — 75 lbf•in)

8 — 12 N•m

(71 — 106 lbf•in)

10.5 — 15 N•m

(93 — 133 lbf•in)

16 N•m (142 lbf•in)

M8 15 N•m(11lbf•ft) 24.5 N•m(18lbf•ft) 31.5 N•m(23lbf•ft) 40 N•m(30lbf•ft)

M10 29 N•m(21lbf•ft) 48 N•m(35lbf•ft) 61 N•m(45lbf•ft) 72.5 N•m(53lbf•ft)

M12 52 N•m(38lbf•ft) 85 N•m(63lbf•ft) 105 N•m(77lbf•ft) 127.5 N•m(94lbf•ft)

M14 85 N•m(63lbf•ft) 135 N•m(100lbf•ft) 170 N•m (125 lbf•ft) 200 N•m (148 lbf•ft)

XXIV

Loading...

Loading...