INTRODUCTION

EPA INTERNET WEB SITE:

http:/www.epa.gov/omswww

SELF-LOCKING FASTENERS

PROCEDURE

The following describes the most common appli-

cation procedures when working with self-locking

fasteners.

Use a metal brush or a screwtap to clean the hole

properly then use a solvent (Methyl-Chloride), let

act during 30 minutes and wipe off. The solventu-

tilization is to ensure the adhesive works properly.

LOCTITE APPLICATION

PROCEDURE

The following describes the most common ap-

plication procedures when working with Loctite

products.

NOTE: Always use proper strength Loctite prod-

uct as recommended in this Shop Manual.

THREADLOCKER

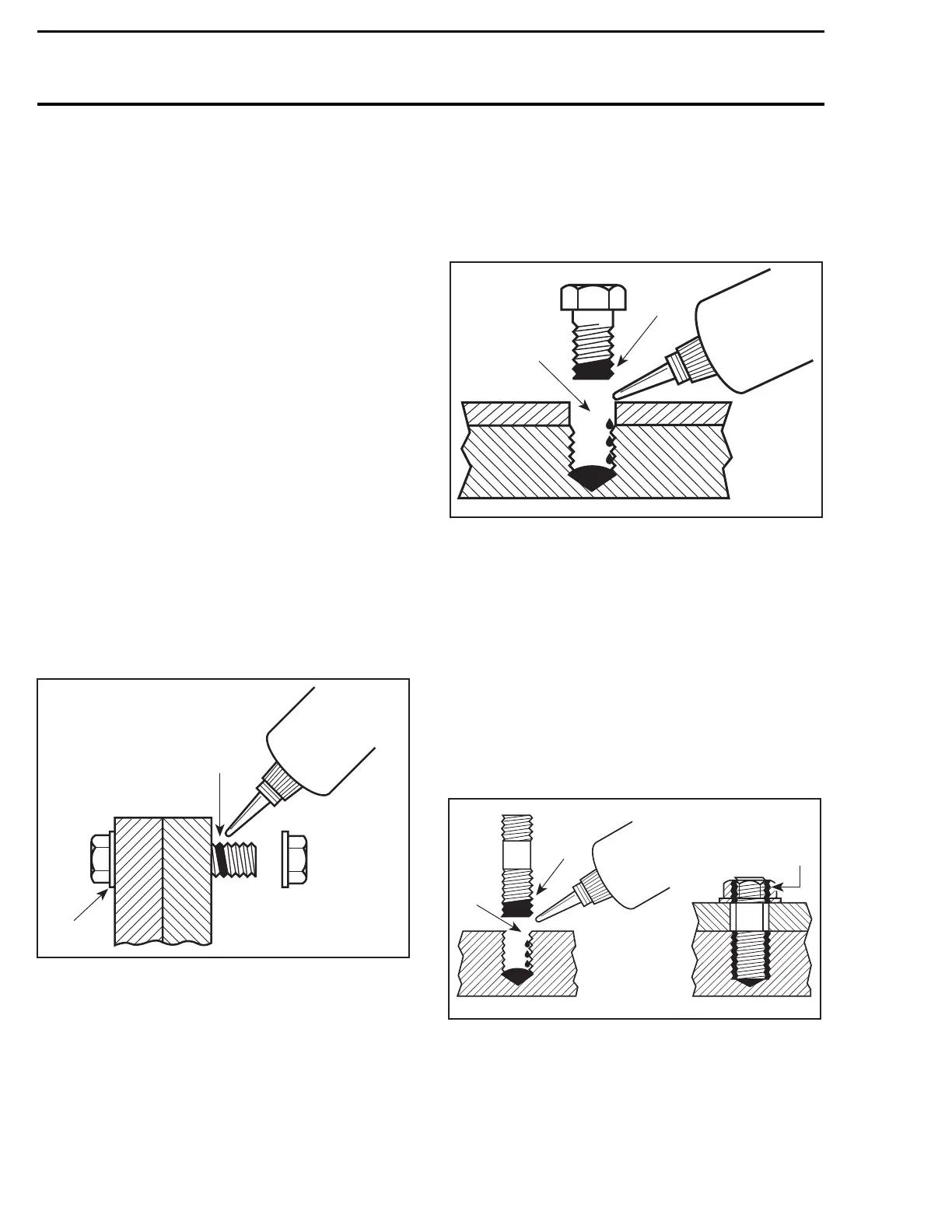

Uncovered Holes (bolts and nuts)

A00A3LA

1

2

1. Apply here

2. Do not apply

– Clean threads (bolt and nut) with solvent.

– Apply Loctite Primer N (P/N 293 800 041

)on

threads and allow to dry.

– Choose proper strength Loctite threadlocker.

– Fit bolt in the hole.

– Apply a few drops of threadlocker at proposed

tightened nut engagement area.

– Position nut and tighten as required.

Blind Holes

A00A3MA

1

2

1. On threads

2. On threads and at the bottom of hole

– Clean threads (bolt and hole) with solvent.

– Apply Loctite Primer N (P/N 293 800 041) on

threads (bolt and nut) and allow to dry for 30

seconds.

– Choose proper strength Loctite threadlocker.

– Apply several drops along the threaded hole and

at the bottom of the hole.

– Apply several drops on bolt threads.

– Tighten as required.

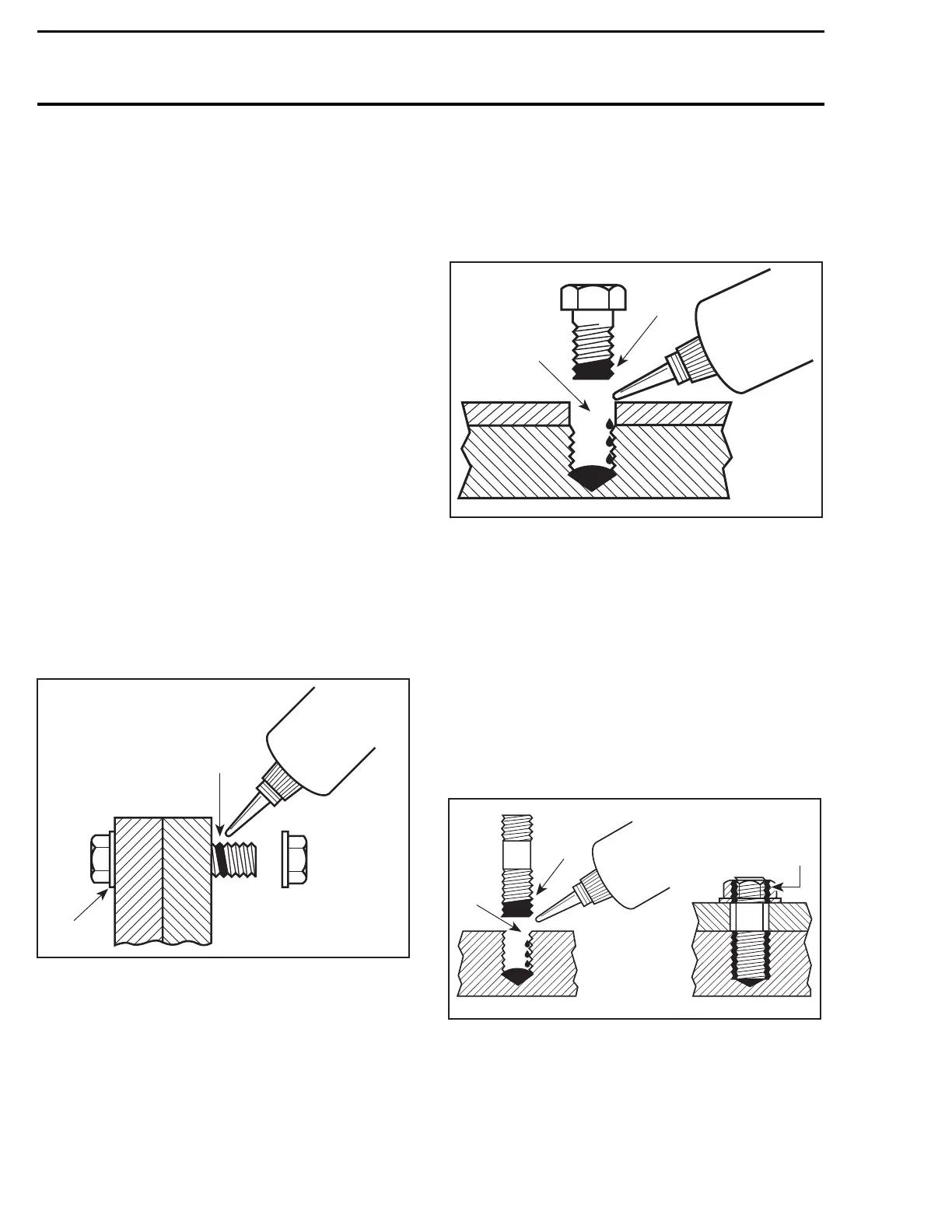

Stud in Blind Holes

A00A5RA

2

1

3

1. On threads

2. On threads and in the hole

3. Onto nut threads

– Clean threads (stud and hole) with solvent.

XX

Loading...

Loading...