Section 04 ENGINE (2-STROKE)

Subsection 04 (TOP END)

Apply Molykote 111 on threads of cylinder head

bolts no. 14.

Torque bolts to 20 N•m(15lbf•ft) as per following

sequence in the next illustration. Repeat the

torquing sequence by retightening to 40 N•m

(30 lbf•ft).

F12D08A

12

11

7

4

8

2

3

1

6

10

9

5

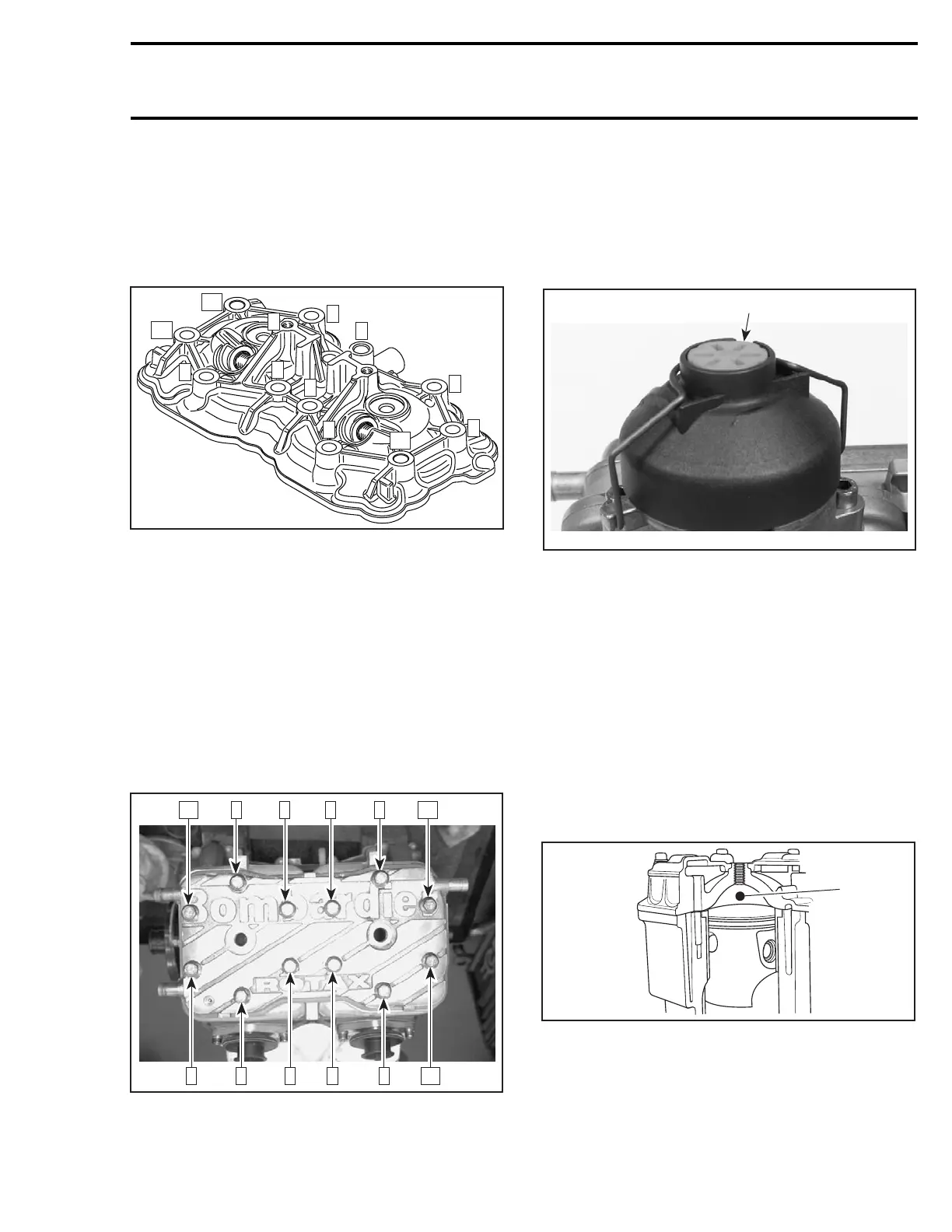

Cylinder Head Cover

717 and 787 RFI Engines

Install cylinder head cover no. 1.

Apply Loctite 243 (blue) below head of screws

no. 14.

Apply also Molykote 111 on threads of screws

no. 14.

Torque cylinder head screws no. 14 to 12 N•m

(106 lbf•in) as per following illustrated sequence.

Repeat the procedure, retightening all screws to

24 N•m(17lbf•ft).

F01D46A

10 8 2 4 6 12

113 1 59 7

TORQUING SEQUENCE

ADJUSTMENT

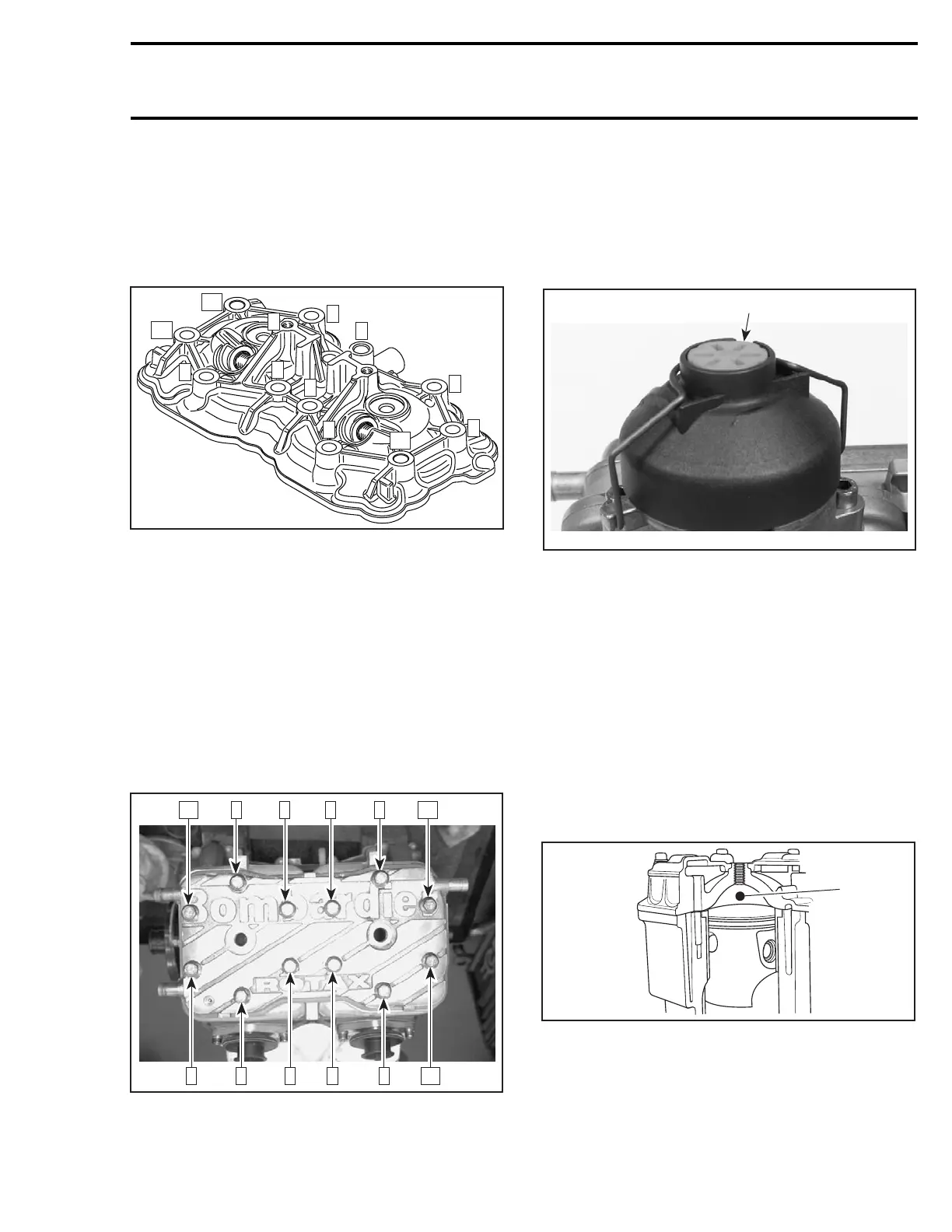

RAVE Valve

787 RFI Engines

Turn the red plastic knob no. 17 until it is flush to

the valve cover.

F00D0GA

1

1. Knob flush with the cover

Combustion Chamber Volume

Measurement

All Engines

NOTE: This procedure is required to determine

the thickness of the cylinder base gasket to be in-

stalled if a crank repair has involved replacement

of connecting rods or if you are experiencing

repetitive engine seizure.

The combustion chamber volume is the region in

the cylinder head above the piston at Top Dead

Center. It is measured with the cylinder head in-

stalledontheengine.

F01D5VA

1

1. Combustion chamber

NOTE: When checking the combustion chamber

volume, engine must be cold, piston must be free

of carbon deposit and cylinder head must be lev-

eled.

smr2004-Complete Line Up 125

Loading...

Loading...