Section 04 ENGINE (2-STROKE)

Subsection 03 (MAGNETO SYSTEM)

DISASSEMBLY

717 Engines

NOTE: The magneto system can be disassembled

without removing the engine from the watercraft.

Magneto Cover

Remove screws no. 11 andwiresupportno. 12,

then withdraw magneto cover no. 1.

Magneto Flywheel and Ring Gear

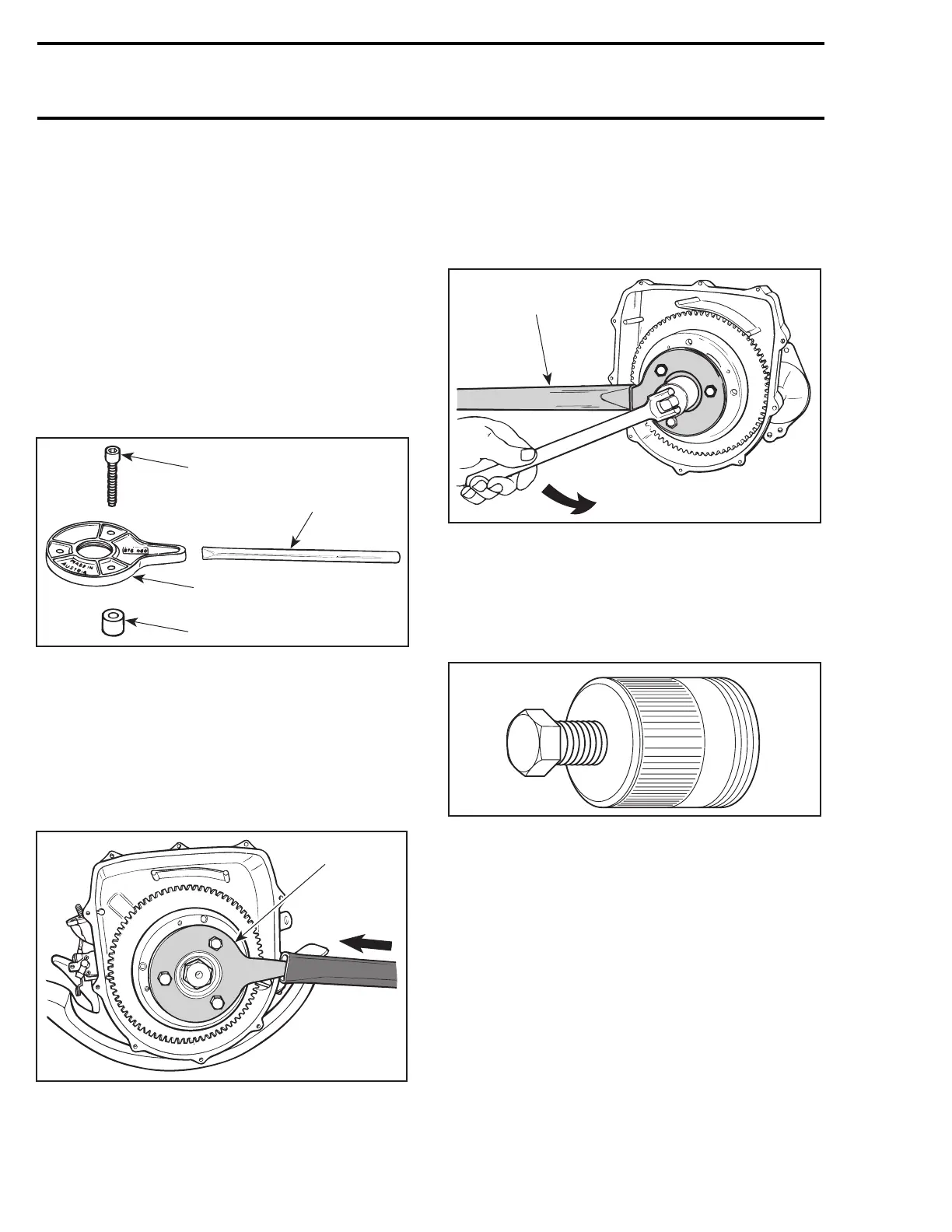

Magneto flywheel no. 2 is locked with puller plate

(P/N 420 876 080), sleeves (P/N 290 847 220) and

extension handle (P/N 295 000 125).

F01D47A

2

3

4

1

1. Screw

2. Extension handle

3. Puller plate

4. Sleeve

Using three M8 x 35 screws (P/N 420 841 591), in-

stall screws through puller plate and slide sleeves

on screws then secure puller plate on magneto fly-

wheel so that sleeves are against ring gear no. 3.

Install extension handle on end of puller plate.

F01D48A

1

TYPICAL

1. Sleeves on opposite side

Using a suitable socket, unscrew retaining nut

no. 13 COUNTERCLOCKWISE when facing it.

NOTE: If socket is found too large to be inserted in

puller plate, machine or grind its outside diameter

as necessary.

F01D4BA

1

TYPICAL

1. Extension handle locking crankshaft

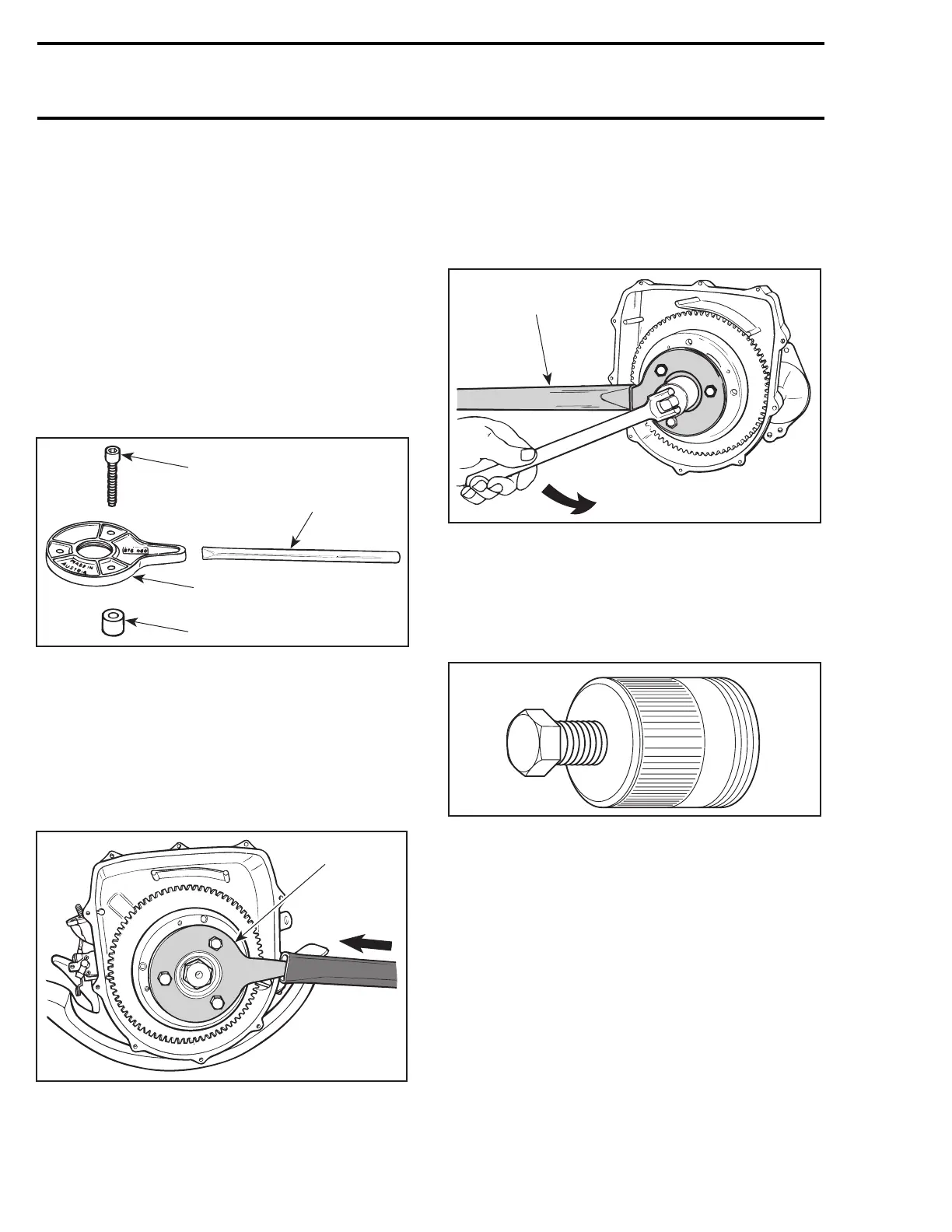

Remove nut no. 13 and lock washer no. 14 from

magneto flywheel.

Magneto flywheel is easily freed from crankshaft

with puller (P/N 529 035 547).

A00C1AA

Fully thread on puller in puller plate.

Tighten puller bolt and at the same time, tap on

bolt head using a hammer to release magneto fly-

wheel from its taper.

86 smr2004-Complete Line Up

Loading...

Loading...