Section 06 ENGINE MANAGEMENT (RFI)

Subsection 03 (COMPONENT INSPECTION )

F07F15A

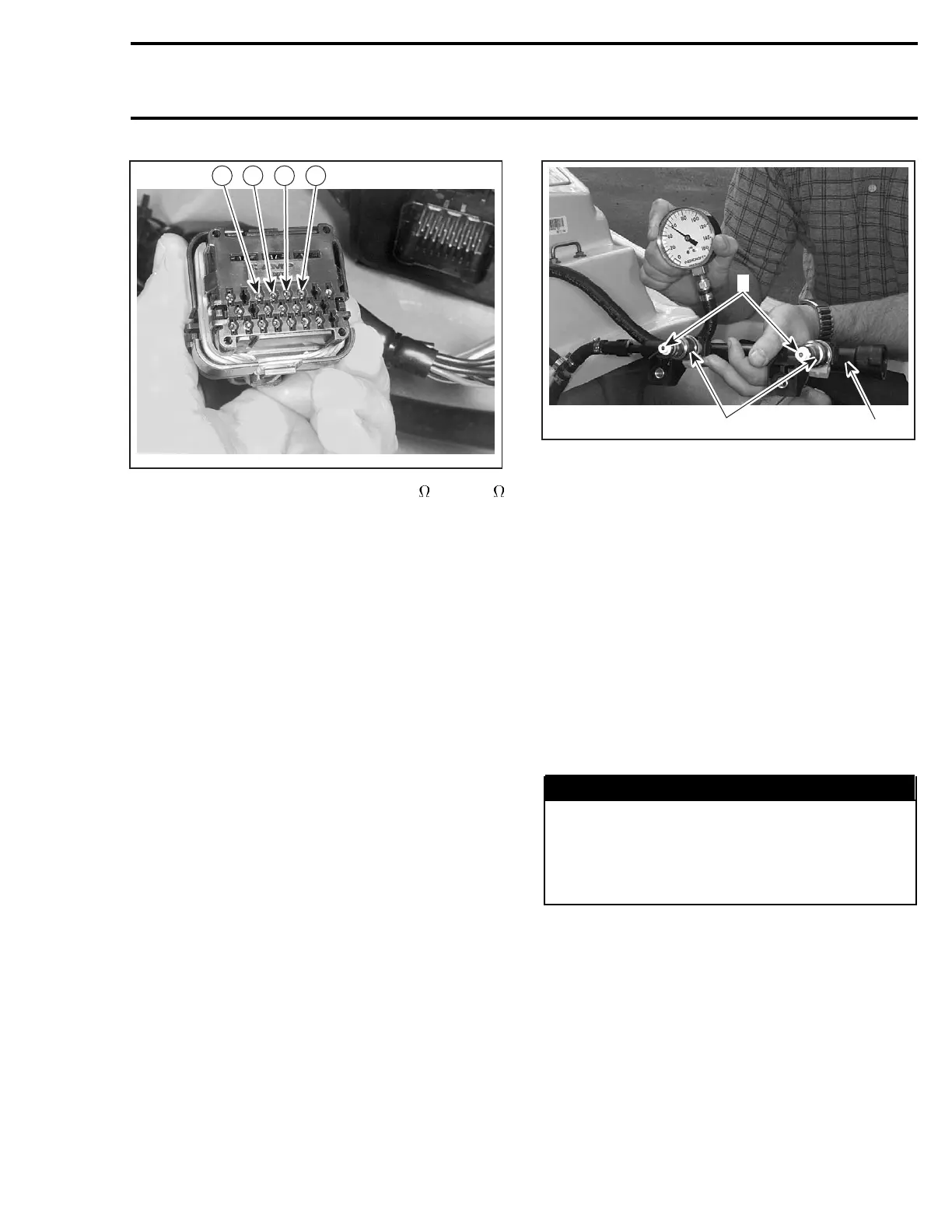

18 19 20 21

The resistance should be between 2.3 and 2.5

at temperature of 20°C(68°F).

If resistance value is incorrect, check wiring har-

ness between AMP plug connector and fuel injec-

tors for damaged wires or bad connections. Re-

pair if necessary.

Recheck resistance value at AMP plug connector

#4.

If not within specification, replace the fuel injector.

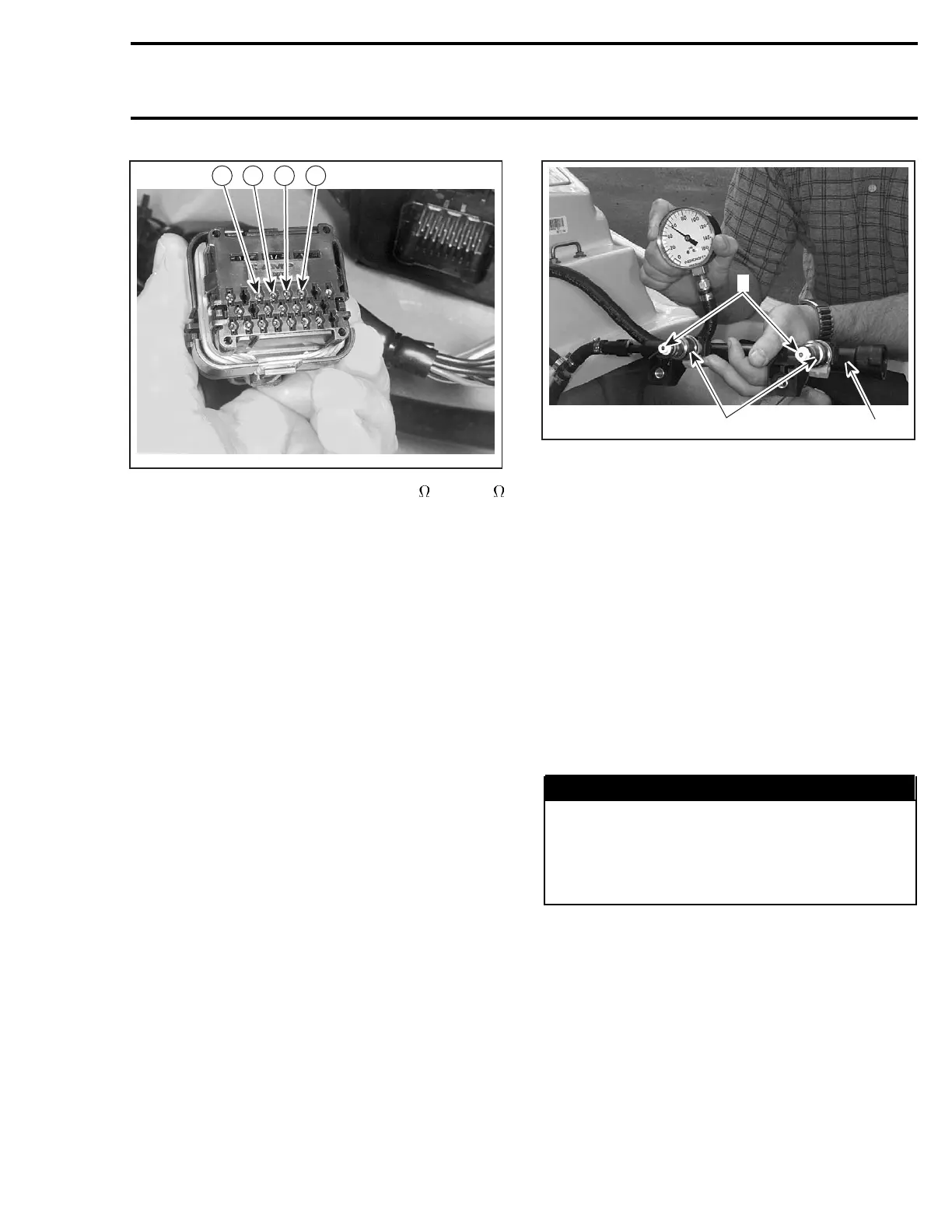

Leakage Test (fuel injectors)

To perform a leakage test, the injectors and fu-

el rail have to be removed from engine. See RE-

MOVAL in this subsection for the procedure.

NOTE: Do not detach injectors from fuel rail.

Reconnect the wire connector of the injector.

Place each injector in a clean bowl.

Install the safety lanyard cap on the switch to ac-

tivate the fuel pump.

Check for fuel leakage from the injector nozzle.

There should be less than 1 drop of fuel per

minute.

2

1

F07F16A

3

1. Fuel injectors

2. Fuel rail

3. Injector nozzles

If not within specification, replace the fuel injec-

tor(s).

LEAK TEST (SUPPLY AND

VENTILATION CIRCUITS)

Refer to FUEL SYSTEM.

HIGH PRESSURE TEST (FUEL

PUMP CIRCUIT)

Before proceeding to the pressure test ensure the

battery is fully charged. Battery voltage must be

over 12 volts.

WARNING

The fuel hose may be under pressure. Cov-

er the fuel line connection with an absorbent

shop rag. Slowly disconnect the fuel hose

toreleasethepressure. Wipeoffanyfuel

spillage inside bilge.

Press on both tabs and pull quick connect fitting

to disconnect the fuel hose from fuel rail.

smr2004-Complete Line Up 311

Loading...

Loading...